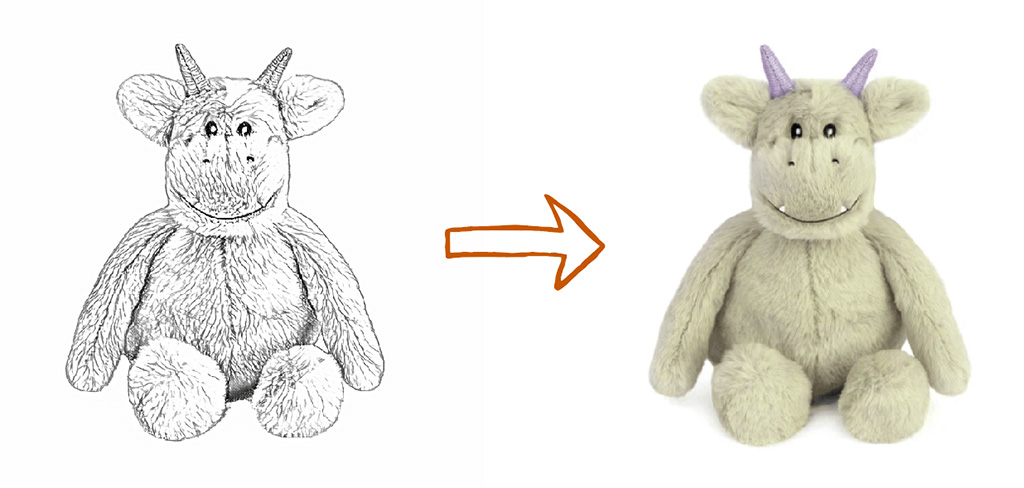

What Happens During Plush Toy Mass Production: A Step-by-Step Overview

Mass production is the stage where your plush toy design finally becomes a large-scale, high-volume product ready for global distribution. Unlike sampling—where experimentation, refinement, and adjustments happen—mass production requires precision, discipline, and strict process control to ensure every unit remains consistent with the approved prototype. A high-quality factory follows a