Accurate plush toy development begins with pattern makers—the specialists responsible for converting flat illustrations into three-dimensional soft sculptures. Their work determines whether a plush toy resembles the original design, maintains correct proportions, and performs well during mass production. Even the best materials and sewing skills cannot correct a poorly engineered pattern. Skilled pattern makers shape the entire development process: from concept accuracy and sample quality to manufacturability, cost control, and consistency across thousands of units. In this guide, we explore how expert pattern making creates high-quality plush toys and why global brands rely on professional pattern teams to bring characters to life.

How Pattern Makers Translate 2D Artwork into Precise 3D Plush Geometry?

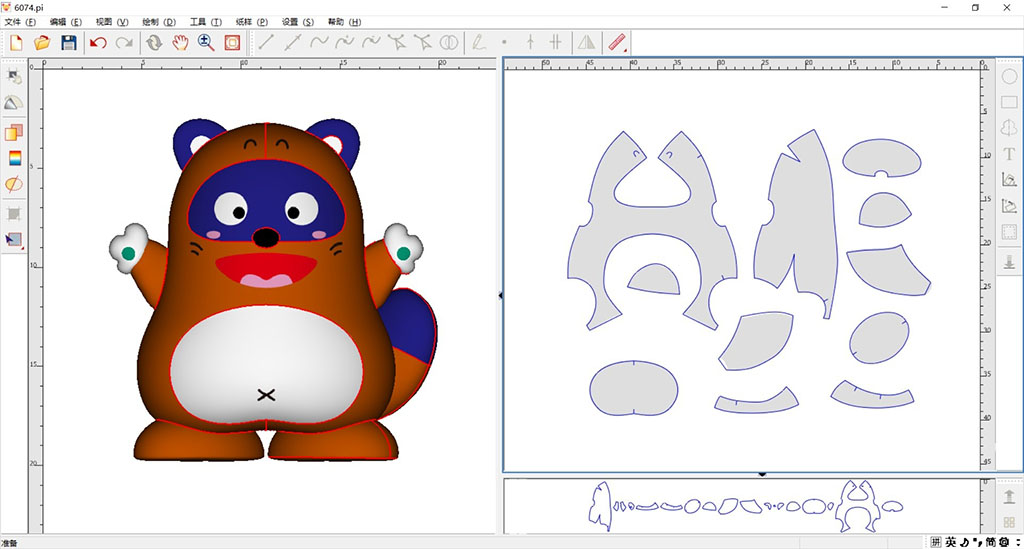

Turning a flat drawing into a volumetric plush toy is a technical and artistic skill. Pattern makers carefully study character artwork—front, side, and sometimes 3D reference—to understand how each curve, angle, and proportion should appear once translated into physical form. They break down the character into geometric shapes, determine how these shapes will wrap around stuffing volume, and design fabric panels that will form a clean, expressive silhouette when assembled.

Pattern makers must compensate for the fact that soft materials distort differently than hard materials. A jawline that looks sharp in a drawing will become rounder when stuffed; an eye that looks perfectly placed in 2D may shift lower when the head expands in 3D. Predicting such transformations is the core skill of pattern making. This interpretation determines the emotional expression and identity of the plush, especially for IP characters where accuracy is critical.

Example: How 2D Features Become 3D Shapes

| 2D Design Element | Pattern Maker Conversion | 3D Plush Impact |

|---|---|---|

| Flat cheek lines | Curved side panels | Creates round facial contour |

| Stylized big head | Multi-panel sphere pattern | Maintains uniform head volume |

| Simple body outline | Segmented torso shapes | Improves structure and posture |

| Printed expression | Embroidery placement mapping | Consistent face replication |

Without expert interpretation, the plush can look distorted, unbalanced, or unlike the original character.

What Technical Decisions Pattern Makers Make to Preserve Character Proportions?

Preserving correct character proportions is one of the most difficult aspects of plush engineering. Plush toys have volume, seams, and stuffing—none of which exist in the original 2D artwork. Pattern makers must make decisions that mathematically and visually correct for these distortions.

They evaluate:

- Head-to-body ratio adjustments once stuffing expands the shape

- Eye spacing & placement, which often shifts after rounding

- Thickness compensation where fabric pile affects visible size

- Curve smoothing, because plush silhouettes must flow naturally

- Panel segmentation, which controls how shapes form without wrinkles

These decisions ensure a character’s personality remains intact. For stylized designs—large eyes, tiny limbs, oversized heads—the pattern maker must re-engineer proportions so they remain recognizable and balanced in plush form.

Pattern Maker Proportion Control Chart

| Area Adjusted | Why It Matters | Typical Adjustment |

|---|---|---|

| Head size | Small variance changes character identity | Reduce or enlarge by 3–8% |

| Limb length | Prevents toy from looking short or uneven | Increase length for fluffier fabrics |

| Eye placement | Influences character emotion | Move upward to counter stuffing inflation |

| Body width | Affects stability and silhouette | Expand chest/torso for balance |

Precise proportioning separates professional plush development from amateur attempts.

How Fabric Behavior, Stretch, and Pile Direction Influence Pattern Drafting?

Fabric is alive—it stretches, compresses, shifts, and reflects differently depending on how it’s used. Pattern makers must understand fabric physics to draft accurate, production-ready patterns.

Key considerations include:

- Stretch direction: Plush fabrics like minky stretch horizontally, which can elongate faces or distort limbs if not compensated.

- Pile direction: Incorrect direction creates unnatural shading or inconsistent texture.

- Thickness & density: The thicker the fabric, the more external curves widen after stuffing.

- Backing strength: Weak backings require deeper seam allowances or reinforcement.

These factors change how a plush toy forms in real life. Two identical patterns will create two different plush toys if different fabrics are used—or if the same fabric is used incorrectly.

Fabric Behavior Impact Table

| Fabric Property | Pattern Maker Adjustment | Result |

|---|---|---|

| Horizontal stretch | Reduce width in panel | Prevents “wide face” distortion |

| Thick pile | Larger seam allowance | Maintains clean curve definition |

| Directional fiber | Map grain consistently | Prevents color shading issues |

| Soft backing | Add stabilizing stitching | Strengthens structural points |

Expert knowledge of textiles is essential to professional plush pattern making.

How Pattern Adjustments Reduce Distortion, Bulk, and Structural Weaknesses?

After the first prototype, pattern makers refine shapes to correct distortions caused by stuffing, seam tension, or material behavior. These adjustments are designed to:

- Smooth uneven curves

- Reduce bulk in multi-layer seam intersections

- Eliminate puckering around tight curves

- Strengthen attachment points like necks or joints

- Improve balance so the toy sits or stands correctly

Pattern refinement is an iterative engineering process. Every adjustment is intentional and based on how the toy performs in three dimensions.

Common Corrective Adjustments

| Issue Found | Adjustment Made | Outcome |

|---|---|---|

| Bulging head seam | Tighten curve radius | More even roundness |

| Crooked face | Re-map embroidery location | Symmetry restored |

| Weak limb attachment | Reinforce seam structure | Increased durability |

| Wrinkled torso | Modified dart or paneling | Smoother silhouette |

High-end plush toys often require 2–4 refinement cycles before reaching perfection.

How Skilled Pattern Makers Improve Sample Accuracy and Reduce Revision Cycles?

A strong pattern team can dramatically shorten the development timeline. When pattern makers correctly interpret artwork and fabric behaviors from the start, the first sample is already close to the final expected result. This reduces:

- Revision rounds

- Development delays

- Sample costs

- Communication back-and-forth

- Risk of misalignment between buyer and factory

Accurate early samples also help avoid mass-production issues later. Clearly defined seam rules, panel shapes, and embroidery placements reduce mistakes when training sewing teams.

Benefits of Expert Pattern Making

| Development Stage | Impact of Skilled Pattern Maker |

|---|---|

| Sample 1 | Higher accuracy, fewer redesigns |

| Sampling rounds | Reduction from 3–5 to 1–2 cycles |

| Production prep | Easier SOP development |

| Mass production | Higher consistency and fewer defects |

| Cost | Lower sampling and revision costs |

Good pattern work saves both time and money while boosting quality.

How Expert Pattern Development Enhances Manufacturability and Mass-Production Consistency?

Patterns determine not only how a plush looks but also how efficiently it can be produced. Experienced pattern makers ensure that designs transition smoothly from prototype to mass production without unexpected complications.

They optimize:

- Seam placement for ease of sewing

- Part segmentation to reduce assembly errors

- Fabric usage efficiency to reduce waste

- Stuffing zones for balanced firmness

- Reinforcement points for safety compliance

- Embroidery layering for stable facial expressions

Factories rely on these optimized patterns to train sewing lines and ensure every unit matches the approved sample. Without these refinements, production becomes inconsistent, costly, and slow.

Manufacturability Optimization Table

| Optimization Area | Pattern Maker Contribution | Mass-Production Benefit |

|---|---|---|

| Seam layout | Simplifies sewing workflow | Faster production |

| Panel count | Balanced for detail vs. efficiency | Lower labor cost |

| Attachment structure | Reinforced joints | Fewer defects |

| Fabric consumption | Efficient layout | Reduced material waste |

| Embroidery mapping | Stable placement | Consistent character faces |

Expert pattern development is the backbone of scalable plush toy production.

Conclusion

Pattern makers are the silent engineers behind every beautiful, accurate plush toy. Their craftsmanship shapes the toy’s structure, expression, safety, durability, and manufacturability. For IP-based designs, premium products, or large-volume orders, skilled pattern makers ensure that every piece—from the first sample to the final shipment—stays true to the brand’s vision.

Factories like Kinwin rely on senior pattern makers trained in global brand standards, IP accuracy, structural engineering, and high-volume manufacturing workflows. Their expertise helps brands reduce revisions, control costs, accelerate sampling, and achieve consistent, high-quality results.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com