In textiles, plush is not just a feeling. It is a specific type of fabric with a pile structure, certain fiber types, and controlled finishing. The choices you make here will decide how your toys feel, how long they last, how they behave in washing, and whether they pass global safety tests.

In this guide, I’ll explain plush material from a factory point of view, but in simple English you can share with your team. We’ll look at how plush is defined, how it is produced, what makes it soft, how it compares to minky, velboa, fleece, and velvet, which tests it must pass, and how manufacturers like us match plush materials to different toy markets.

What is plush material and how is it defined in textiles?

In textile language, plush material is a fabric with a raised pile surface that feels soft and fuzzy to the touch. It is usually made on a knitting or weaving machine with extra yarns that form this pile. For toy use, the pile is typically short to medium length and very dense, so it feels rich but still safe and durable.

In simple words:

Plush material = a fabric with tiny fibers standing up from the surface, creating a soft, furry layer on top of a stable backing.

Key points of plush definition

- Pile structure

Plush has a pile: many short fibers standing up from the base fabric. This is what you feel when you stroke the toy. - Base (backing) construction

Under the pile, there is a base fabric—usually a warp-knit or weft-knit backing in toy applications. This backing controls stretch, shape stability, and seam strength. - Fiber type

For modern plush toys, the pile fibers are usually polyester. Sometimes there are blends (for example, polyester with a bit of acrylic), but pure polyester is dominant because it is soft, colorfast, and easy to wash. - Surface height and density

Plush can be short pile, medium, or long. For toys, we mainly use short and medium for everyday plush, and long plush / faux fur only when we want a very furry effect. Density matters: a dense plush looks rich and hides the backing; a thin plush can look cheap and patchy. - Usage in toys

When we say “plush material” in toy manufacturing, we usually mean polyester pile fabric used on the surface of plush toys, not the stuffing inside. The stuffing is a separate topic.

Definition of plush material in textiles

| Aspect | What It Means in Textiles | Why It Matters for Plush Toys |

|---|---|---|

| Pile structure | Raised fibers standing up from the base fabric | Creates the soft, fuzzy touch that customers love |

| Base (backing) | Knitted or woven ground that holds the pile | Controls stretch, seam strength, and shape stability |

| Fiber composition | Usually polyester, sometimes blends | Affects softness, colorfastness, wash behavior, and safety |

| Pile height | Length of fibers: short, medium, or long | Short for baby and fine detail; longer for fluffy, dramatic look |

| Pile density & GSM | How many fibers per area; grams per square meter | High density = richer feel, better coverage, fewer bald spots |

| Toy usage definition | Plush fabric = outer material of soft toys (not stuffing) | Helps you brief factories clearly and avoid misunderstandings |

Once you see plush as a structured textile, you can ask better questions: What is the GSM? What is the pile height? Is the backing warp-knit or weft-knit? All of these answers will affect your final product.

How is plush fabric produced and finished for toy applications?

To turn yarn into plush fabric, mills go through several production and finishing steps. As a buyer, you don’t need to run a knitting machine yourself, but understanding the main steps helps you judge quality and costs more accurately.

1. Knitting or weaving the base with pile

Most toy plush fabrics are made on knitting machines, especially warp-knit or circular-knit machines. The machine feeds yarns to create:

- a base layer (the backing), and

- pile loops that stand up from the base.

In some constructions, these pile loops are later cut to form a cut pile (velour-like surface); in others, they stay as loops or go through special textures.

2. Raising and shearing

To get that smooth plush feel, mills then:

- Brush or raise the surface to lift up fibers,

- Shear the pile to a controlled height, so it is even and feels smooth,

- Sometimes double-shear to refine the surface further.

This step has a big impact on:

- how soft the fabric feels,

- how neat the surface looks,

- how well embroidery and printing will appear.

3. Dyeing and printing

Plush is usually dyed in solid colors using disperse dyes for polyester. For more complex designs, mills may:

- use printing (screen or digital),

- or patterns can be created using embossing or burnout techniques.

For toys, we need toy-grade dyes and good colorfastness to saliva, sweat, rubbing, and washing.

4. Finishing for toys

Before plush goes to toy factories, mills can add special finishes:

- Anti-pilling treatment to reduce pilling and fuzz balls,

- Brushing and sueding to improve softness,

- Backing treatments to stabilize the base and reduce stretching,

- Special finishes like anti-static or specific hand-feel.

For baby and children’s toys, we choose finishes that are safe, low-odor, and tested.

Production and finishing of plush fabric for toys

| Stage | What Happens | Effect on Fabric | Buyer Questions You Can Ask |

|---|---|---|---|

| Knitting / weaving | Create base + pile loops using polyester yarn | Decides backing stability, stretch, pile density | Is this warp-knit or weft-knit? What is GSM and density? |

| Raising & brushing | Lift fibers and create fluffy surface | Increases softness and volume | How does this plush feel compared to your standard grade? |

| Shearing & surface leveling | Cut pile to a controlled, even height | Gives smooth, clean surface; supports clear embroidery/prints | What is the pile height in mm? |

| Dyeing | Color the fabric with toy-grade dyes | Defines final color; must be colorfast | Can you show colorfastness test data (wash, rub, saliva)? |

| Printing / embossing (if any) | Add patterns or designs on the surface | Creates special designs and branding options | Is printing toy-safe and tested according to EN71/ASTM? |

| Anti-pilling & other finishes | Chemical and mechanical treatments | Reduces pilling, improves hand-feel | Does this plush have anti-pilling treatment? |

| Backing stabilization | Extra processes to strengthen backing | Reduces distortion, seam slippage | Is the backing stable enough for detailed toy shapes? |

When you understand these steps, you also understand where costs come from. Super-soft, dense, anti-pilling plush with stable backing and good colorfastness will never be at rock-bottom prices—and that is often a good thing for your brand.

What fiber compositions and pile constructions create plush softness?

Plush softness is not just magic. It comes from fiber type, fiber fineness, pile height, pile density, and the backing design working together. When these are balanced, plush feels luxurious and still passes durability tests.

Fiber composition

For toy plush, the main fiber is polyester. It is:

- soft and flexible,

- easy to dye with bright, stable colors,

- strong enough for repeated hugs and washing,

- and compatible with recycled versions (like rPET).

Sometimes mills blend in other fibers (for example, acrylic), but pure polyester is the most common and easiest to control in testing.

Fiber fineness (denier)

Denier describes how thick or fine each filament of fiber is.

- Lower denier (microfiber) = thinner fibers = softer, silkier plush.

- Higher denier = thicker fibers = more robust but less silky.

Modern ultra-soft plush, especially minky-type fabrics, often use microfibers to get that “buttery” touch.

Pile height and density

- Pile height: shorter pile feels clean and is easier to keep neat; longer pile feels fluffier but can tangle and shed more.

- Density: how many fibers are packed into a given area. More density = richer, fuller hand-feel and better coverage.

Softness also depends on how tightly the pile is packed. Thin plush with low density can feel rough and show the backing through the fibers.

Backing construction

The backing acts like the skeleton. A more stable backing:

- prevents too much stretching,

- holds seams strongly,

- supports embroidery and appliqué.

If the backing is weak, even soft pile will not save the fabric from shape distortion or seam problems.

Factors that create plush softness

| Factor | Options / Range | Effect on Softness and Feel | What You Can Specify or Ask For |

|---|---|---|---|

| Fiber composition | Polyester, recycled polyester, sometimes blends | Polyester gives soft, colorfast, washable plush; rPET supports eco story | Ask if fiber is virgin polyester or recycled (rPET) |

| Fiber fineness | Standard denier vs microfiber (low denier) | Microfiber feels silkier and “buttery”; standard denier feels more basic | Ask if this is microfiber plush or standard plush |

| Pile height | Short (1–3 mm), medium (3–6 mm), long (6+ mm) | Short = clean, baby-friendly; medium = balanced; long = fluffy and dramatic | Request pile height in mm for each design |

| Pile density & GSM | Lower GSM vs medium vs higher GSM | Higher GSM and density = richer, more expensive feel | Ask for GSM and compare samples side by side |

| Backing stability | Light knit vs dense, stable warp-knit backing | Stable backing improves durability and shape retention | Ask how stable the backing is and check for stretch |

| Finishing (brushing, sueding, anti-pilling) | Different finishing recipes and intensities | Can make same structure feel much softer or more matte | Request specific hand-feel references (e.g., like sample X) |

If you tell your factory “we want very soft plush for babies, but also low lint and easy washing,” we will choose microfiber, short or medium pile, good density, and stable backing, then test it for shedding and pilling.

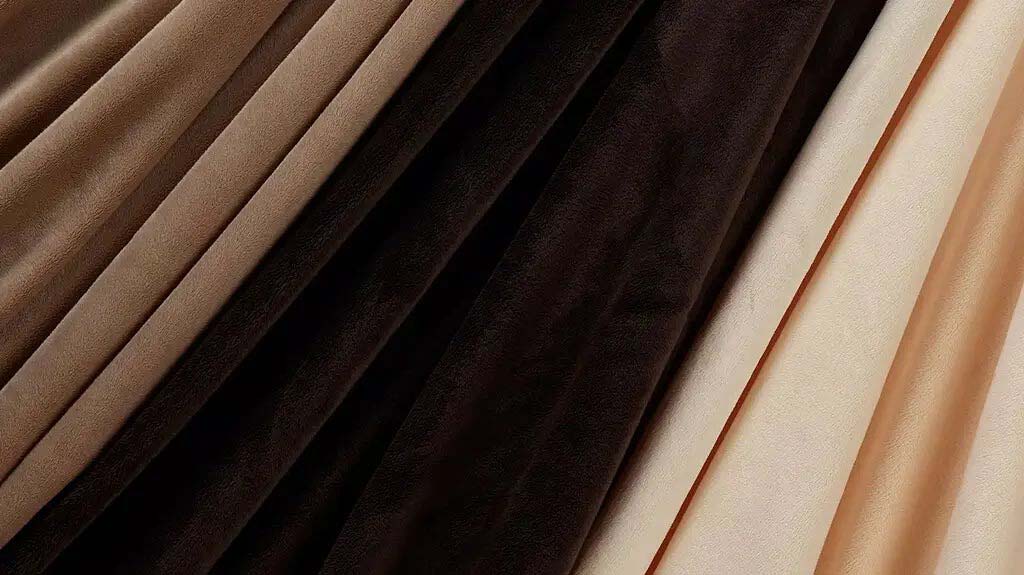

How does plush differ from minky, velboa, fleece, and velvet?

Many buyers use words like “plush,” “minky,” “velboa,” “fleece,” and “velvet” as if they were all the same. In textiles, these names describe specific constructions and finishes, even though they all live in the “soft fabric” family.

Plush vs minky

You can think of minky as a type of plush made with very fine fibers and a short, sheared pile. It is:

- extremely soft and silky,

- often has a gentle sheen,

- very popular for baby items and squishy plushies.

So, minky is plush, but not all plush is minky. General plush may be a bit less silky or use different finishing.

Plush vs velboa

Velboa is also a plush fabric but with very short, dense pile. It feels smooth and slightly firm, not fluffy. It is used when you want:

- crisp facial details,

- clean edges for embroidery and prints,

- low lint and high durability.

Velboa is perfect for faces, small plush, and logo panels. It is less “cuddly” than minky, but better for detail.

Plush vs fleece

Fleece is a brushed knit (usually polyester) but not a classic pile plush with separate upright fibers. It feels cozy and matte, like a sweatshirt or blanket.

- Plush: fuzzy pile specifically designed for toys and soft items.

- Fleece: thicker brushed surface, great for clothing, blankets, and sometimes body parts of plush, especially for budget lines.

Fleece is more cost-effective, but the feeling is different from silky plush.

Plush vs velvet

Velvet is traditionally a woven pile fabric with a very short, dense, and smooth pile, often with a strong sheen. It is widely used in fashion and home textiles.

In toys, we do use velvet-like fabrics sometimes, but more often we use knitted plush because it is:

- more stretchable and forgiving,

- easier to sew into complex 3D shapes,

- and more comfortable for hugging.

Comparison: plush, minky, velboa, fleece, velvet

| Fabric Type | Construction & Surface | Typical Feel & Look | Common Toy Uses | Key Strengths | Things to Watch |

|---|---|---|---|---|---|

| Plush (general) | Knitted pile fabric, cut or raised surface | Soft, fuzzy, can be short or longer pile | General plush toys, teddy bears, animals, cushions | Versatile; wide range of softness and densities | Quality varies widely by GSM and finishing |

| Minky | Microfiber plush, short sheared pile | Very silky, “buttery,” slight sheen | Baby plush, Squishmallow-type plush, pillows, comforters | High perceived value; extremely soft | Must control pilling and lint; higher cost than basic plush |

| Velboa | Ultra-short, very dense pile plush | Smooth, firm, crisp surface | Faces, small plushies, logo panels, detail areas | Excellent detail, low lint, high durability | Full-body velboa can feel less cuddly |

| Fleece | Brushed knit (not classic pile) | Cozy, matte, sweatshirt-like | Plush clothing, blankets, budget plush bodies | Cost-effective, warm, forgiving in wear | Low-grade fleece pills and looks old quickly |

| Velvet | Woven pile, very short and dense | Smooth, elegant, strong sheen | Some fashion-oriented plush, décor items | Luxurious appearance; sharp color | Less stretch; more difficult for complex plush shapes |

When you brief your factory, be specific: “We want minky body with velboa face,” or “We prefer short plush instead of fleece,” instead of only saying “soft fabric.” This will reduce sampling rounds and cost surprises.

What tests and standards ensure plush fabric safety and durability?

Even the softest plush material must also be safe and durable, especially when used for children’s toys. This is why we test plush fabrics according to toy standards and textile lab methods before using them in production.

Safety and regulatory tests

For toys going to Europe, the USA, and many other markets, we consider:

- EN 71 (Europe)

- EN 71-1: mechanical and physical properties (seams, small parts)

- EN 71-2: flammability

- EN 71-3: migration of certain elements (heavy metals)

- ASTM F963 (USA) – toy safety standard affecting mechanical, flammability, and some chemical aspects.

- CPSIA (USA) – defines limits for lead and certain phthalates, and requires tracking labels.

Plush fabric is a key part of these tests. The dyes and finishes must not contain banned substances, and the fabric must behave correctly under flame tests.

Textile performance tests for plush

Beyond legal safety, we perform textile performance tests to make sure plush can survive real use:

- Colorfastness (to washing, rubbing, saliva, sweat): fabric should not bleed or fade easily.

- Pilling resistance: surface should not form too many fuzz balls.

- Abrasion resistance: fabric should not wear through quickly.

- Tear and seam slippage: fabric should not tear or slip under tension at seams.

- Lint and fiber shedding: especially important for baby plush; we want low loose fiber release.

For baby and under-3 products, these tests become even more critical.

Optional certifications

Some buyers also request textile certifications like OEKO-TEX® Standard 100, especially for fabrics that will touch baby skin. This is not a toy regulation, but a textile safety label that many parents recognize.

Safety and durability tests for plush fabric

| Test / Standard | What It Checks | Impact on Plush Material | What You Should Confirm with Your Supplier |

|---|---|---|---|

| EN 71-1 (EU) | Mechanical/physical properties (seams, attachments) | Backing and seams must be strong; plush must not tear easily | Ask if plush and construction pass EN 71-1 for toys |

| EN 71-2 (EU) | Flammability | Plush must not burn too quickly or dangerously | Confirm plush is toy-grade and flammability-tested |

| EN 71-3 (EU) | Migration of elements (heavy metals) | Dyes and finishes must be free of restricted substances | Request EN 71-3 test reports for fabrics and prints |

| ASTM F963 (USA) | Toy safety (mechanical, flammability, some chemicals) | Similar demands as EN 71; plush must match test samples | Ensure your plush spec is tested for both EU and US if needed |

| CPSIA (USA) | Lead and certain phthalates, plus tracking labels | Affects prints, coatings, and some accessories on plush | Confirm any printed or coated plush is CPSIA-compliant |

| Colorfastness tests | Wash, rub, saliva, sweat | Plush should not bleed color onto skin, clothing, or mouths | Ask for colorfastness test results and rating levels |

| Pilling / abrasion tests | Surface wear and appearance after use | Plush should stay neat, not become ugly with fuzz balls | Request pilling and abrasion ratings for your key plush |

| Lint shedding checks | Loose fibers and fuzz release | Especially important for baby and under-3 plush | Ask how they control and test lint and shedding |

| OEKO-TEX® Standard 100 (opt) | Human-ecological textile safety | Lower risk of harmful substances in plush fabric | For baby lines, ask if the fabric has OEKO-TEX® status |

You do not need to memorize each test code. But you should always ask for real test reports that match your actual plush material spec, not just “similar” fabrics.

How do manufacturers select plush materials for different toy markets?

Not every plush material suits every market. A baby lovey, a budget carnival prize, a premium collectible bear, and a TikTok-friendly squishy pillow all need different plush specs. Good manufacturers select plush based on who will use the toy, how it will be sold, and what story the brand wants to tell.

Baby and toddler market

For baby products and under-3 toys, we focus on:

- Short, dense plush or minky for low lint and easy cleaning.

- Soft but firm enough backing for seam strength.

- Full embroidered faces, no hard eyes.

- Strong colorfastness to saliva and sweat.

- Optional OEKO-TEX® or similar textile safety labels.

This plush should feel very soft but also very clean and safe in laboratory tests.

Mass-market children’s plush

For general children’s plush in toy shops, supermarkets, and online platforms, we balance:

- Softness and cost using short plush, minky, or fleece combinations.

- Durability and washability, so parents can clean toys easily.

- Color variety and print options for collections and IP characters.

Here, plush needs to be pleasant to touch, but also robust to everyday play.

Collector and premium plush

For adult collectors or premium gift segments, we can upgrade to:

- Long plush or faux fur for rich look and feel.

- Special finishes (tipped fur, curly textures, high GSM).

- More complex patterns and clothing.

The plush can be less “baby-proof” but more artistic and dramatic. Age grading is often 14+.

Décor and lifestyle plush

Décor plush, cushions, and room accessories may use:

- Minky for soft pastel, lifestyle looks,

- Velvet-like plush for elegant décor,

- Neutral colors and textures that match interior trends.

Here, the plush must photograph well and stay attractive over time on sofas, beds, and chairs.

Promotional and licensing plush

For promotional items or IP collaborations, we select plush that:

- Matches brand image and character design (color accuracy and texture),

- Works at the target price point,

- Can be duplicated reliably across large campaigns.

Sometimes we use one core plush base and change color, embroidery, or print to fit different events or partners.

Plush material selection for different toy markets

| Market Segment | Typical Plush Choice | Key Priorities | Example Selection Strategy |

|---|---|---|---|

| Baby & toddler toys | Short, dense minky or short plush; sometimes velboa | Safety, low lint, washability, very soft feel | OEKO-TEX® or tested plush; embroidered faces; calm colors |

| Mass-market children’s plush | Short plush, minky, velboa details, some fleece usage | Softness, durability, competitive cost, bright colors | Mix minky for hero SKUs and short plush for others |

| Collector & premium plush | Long plush, faux fur, high-GSM plush | Rich look, unique texture, high perceived value | Use special faux fur or long plush for main characters |

| Décor & lifestyle plush | Minky, velvet-like plush, aesthetic short plush | Visual impact, comfort, on-trend colors and textures | Choose plush that photographs beautifully and resists pilling |

| Promotional & licensing plush | Reliable, mid-range plush with good color matching | Brand identity, logo clarity, cost control | Short plush or velboa for defined shapes and logos |

| Eco-focused plush lines | rPET plush (minky/short plush), recycled stuffing | Sustainability story, testable performance | Use certified rPET with clear recycled content claims |

At Kinwin, my team usually starts each project by asking three simple questions:

- Who will hug this toy?

- Where will it be sold?

- What feeling do you want your customer to have in 2–3 years, not just on day one?

Then we propose 1–2 plush options for you to compare in real samples.

Conclusion

A good plush toy is safe, soft, durable, and appealing while also offering branding opportunities. The plush material you choose—its fiber composition, pile construction, backing, finishing, and testing—will decide how your toys feel, how long they last, and how easily they pass global safety standards.

At Kinwin, we help global buyers select and standardize plush materials that match their target age groups, markets, budgets, and sustainability goals. From baby-safe short plush to high-GSM faux fur and rPET minky, my team can guide you from fabric swatch to finished shipment with clear testing and quality control. Contact us at [email protected] or visit kinwintoys.com to discuss your next plush project and explore how our factory can support your success.