From the outside, a plushie looks simple. In manufacturing, it is a system of materials: outer fabrics, inner stuffing, threads, trims, and hidden parts that all work together. If any material is chosen badly, the result can be rough touch, weak seams, safety problems, or poor reviews.

In this guide, I’ll walk you through what plushies are made of from a factory point of view, using simple English and clear tables so you can brief suppliers better, ask the right questions, and build plush lines that feel premium and pass strict safety tests.

What core materials are used to make plushies?

Every plushie is built from a few core material groups. If you understand these groups, you can quickly see where quality is high and where risk appears. At Kinwin, we always start every project by mapping these basic building blocks:

- Outer fabrics – what people see and touch.

- Inner stuffing – what controls shape, bounce, and hug feel.

- Threads and internal support – what holds everything together.

- Trims and accessories – what give expression and personality.

- Labels and packaging – what carry safety and brand information.

Outer fabrics

The outer fabric is the “face” of your plushie. Today, we mainly use polyester plush fabrics, such as minky, velboa, short plush, long plush, faux fur, and fleece. These fabrics are chosen because they are:

- Soft and pleasant to touch

- Colorfast under wash and use

- Strong enough for children’s play

- Compatible with toy safety tests

We may also use cotton knits, terry, or blends as main fabrics in baby comforters, dolls, or clothing parts.

Inner stuffing

Inside the plushie, the core material is usually polyester fiberfill (PP cotton) or recycled polyester fiberfill (rPET). For special effects, we add pellets, beads, or foam in controlled ways to change weight and structure. The stuffing is what makes a plushie feel “cheap and flat” or “full and premium.”

Threads, support, and hidden components

You rarely see them, but sewing threads, interlining, foam pieces, and pouches are critical. Strong thread and stable backings prevent seam failures and distortion. Inner pouches keep pellets safe and contained. Light foam can help ears stand up or muzzles keep their shape.

Trims and accessories

Eyes, noses, embroidery thread, appliqué fabrics, clothes, ribbons, and labels all belong to this group. They add expression and branding but must be controlled for small parts, sharp edges, and durability.

Core materials used to build plushies

| Material Group | Typical Examples | Function in the Plushie | What you should focus on as a buyer |

|---|---|---|---|

| Outer fabrics | Minky, velboa, fleece, short plush, long plush, faux fur, cotton knit/terry | Define touch, look, and first impression | Softness, lint level, wash performance, and price tier |

| Inner stuffing | Polyester fiberfill, rPET fiberfill, pellet pouches, foam | Control hug feel, volume, and weight | Softness vs firmness, weight balance, and eco options |

| Sewing threads & support | Polyester thread, interlining, foam sheets, internal pouches | Hold shape, strengthen seams, stabilize special parts | Seam strength, shape control, and consistent construction |

| Trims & accessories | Embroidery thread, safety eyes/noses, felt patches, clothing fabrics, ribbons | Provide facial features, decorations, and brand details | Safety (no small parts for babies), durability, and brand look |

| Labels & packaging | Woven labels, care labels, hangtags, swing tags, polybags, cartons | Communicate safety, care, and branding; protect product during transit | Correct info, compliance marks, and packaging that suits your channels |

When you understand these layers, you can see that a “plushie” is not one material—it is a designed material system. Good factories manage each part with clear standards instead of guessing.

How do fabrics like minky, velboa, and fleece define plush texture?

The first thing your customer feels is the outer fabric. Even if the inside stuffing is perfect, a rough or low-grade surface will make the plushie feel cheap. In modern plush manufacturing, three fabric names appear again and again: minky, velboa, and fleece.

Minky – silky, premium softness

Minky (micro-plush) uses very fine fibers with a short, sheared pile. It feels:

- Silky and “buttery”

- Smooth with a slight sheen

- Very soft even with a thin layer

Because of this, minky is popular for:

- Baby plush and loveys

- Squishmallow-style round plushies

- Pillow plush and comfort cushions

- Premium character lines

The main watch-outs are pilling and lint if you choose low-grade minky or very long pile. At Kinwin, we test each lot for pile stability, colorfastness, and wash behavior before using it for baby or high-wash products.

Velboa – crisp, smooth, detail-friendly

Velboa has ultra-short, dense pile. It feels smooth and slightly firmer than minky. Velboa is ideal when you need:

- Very clear facial lines and markings

- Clean edges for embroidery or printing

- Low lint and good durability

We often use velboa on:

- Faces and belly panels

- Small plushies with lots of tiny details

- Logo areas, badges, and shapes with sharp outlines

Sometimes a single plush uses minky for the body and velboa for the face to combine softness with precision.

Fleece – cozy and cost-effective

Fleece is a brushed knit, usually polyester. It feels:

- Matte and cozy

- Similar to a sweatshirt or blanket

- Slightly thicker and warmer

Fleece is often used for:

- Clothing on plush (hoodies, jackets, scarves)

- Budget or mid-range plush bodies

- Plush blankets and soft accessories

High-quality anti-pill fleece holds up well after many washes. Low-grade fleece pills quickly and can make the plushie look old. Correct grade choice is critical for brand image.

Comparing minky, velboa, and fleece for plushies

| Fabric | Hand-Feel & Look | Typical Applications | Key Advantages | Key Watch-outs |

|---|---|---|---|---|

| Minky | Very soft, silky, light sheen | Baby plushies, Squishmallow-style toys, pillows, premium SKUs | Strong premium feel, loved by children and adults | Must control pilling, lint, and colorfastness |

| Velboa | Smooth, ultra-short pile, crisp appearance | Faces, small plushies, detailed characters, logo areas | Excellent detail, low lint, good durability | Full-body velboa can feel slightly less “cuddly” |

| Fleece | Cozy, matte, sweatshirt-like | Plush clothing, blankets, budget plush, soft books | Cost-effective, warm, forgiving in wear | Low-grade fleece pills and looks old quickly |

When you brief a factory, do not just say “soft fabric.” Specify whether you want minky softness, velboa crispness, or fleece coziness, and for which parts of the plushie. That detail will push your quote and your samples in the right direction from the beginning.

What stuffing materials provide softness, structure, and resilience?

If outer fabric is the skin of a plushie, then stuffing is the muscle and heart. It controls how the plushie feels when hugged, how it sits or stands, and how it looks over time. Even with the same pattern and fabric, two plushies can feel completely different if the stuffing type and density are different.

Polyester fiberfill – the main champion

Most plushies in global markets use polyester fiberfill (also called PP cotton) as the primary stuffing. It is:

- Soft and bouncy

- Lightweight

- Easy to wash and dry

- Stable and low odor when high quality

We can fine-tune the feel by changing:

- Fiber fineness (denier) – finer fibers feel softer.

- Crimp and length – affect bounce and loft.

- Stuffing density – more grams = firmer, fewer grams = softer and more floppy.

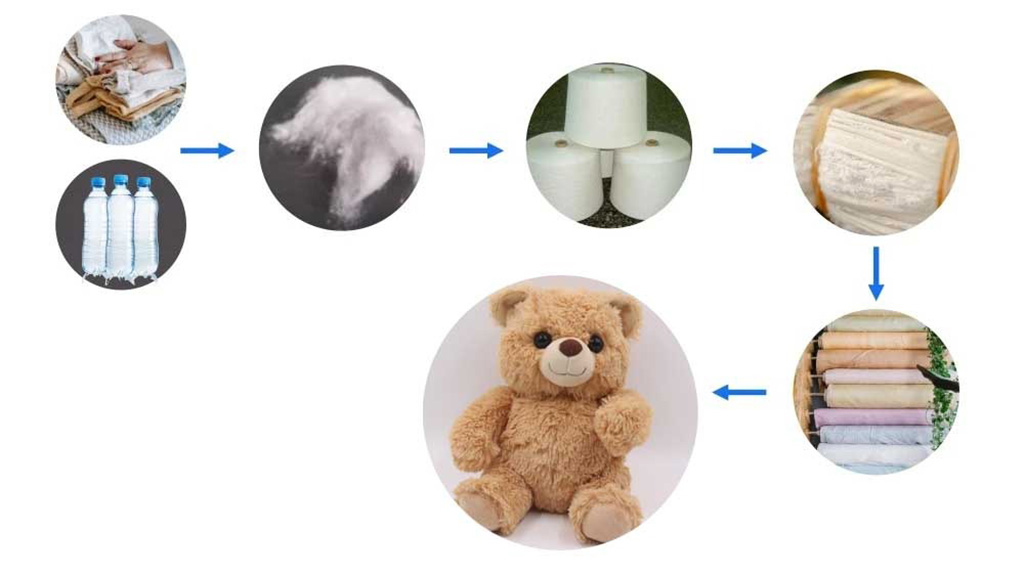

Recycled polyester fiberfill (rPET)

For eco lines, we use recycled polyester fiberfill, made from recycled plastic, often bottles. Good rPET fiberfill can feel almost the same as standard fiberfill, but supports a sustainability story. It must still pass:

- Cleanliness checks

- Odor checks

- Safety tests (EN 71, ASTM, etc.)

Pellets, beads, and foam

To change weight and structure, we sometimes add:

- Pellets/beads in pouches – to add weight in the base or belly, or to create a “bean bag” feeling.

- Foam pieces or inserts – to support muzzles, long bodies, or big heads.

Pellets must be locked into sealed inner bags and are usually not used for under-3 toys. Foam is more common in large mascots, cushions, or décor plush.

Stuffing materials and their roles

| Stuffing Type | Main Function | Feel & Performance | When to Use It |

|---|---|---|---|

| Polyester fiberfill | Core stuffing for most plushies | Light, bouncy, soft; holds shape with proper density | Everyday plushies, children’s toys, gift plush |

| Recycled polyester fiberfill | Eco alternative to regular fiberfill | Very similar to normal fiberfill; supports eco claims | Eco-focused plush lines, brands with sustainability goals |

| Pellets / beads (in pouches) | Add weight and “beanbag” effect | Heavy, shifting feel; grounding and sensory | Weighted plushies, sitting bases, sensory or adult relaxation |

| Foam pieces / cores | Provide structure | Firmer where used; keeps sharp or tall shapes | Large mascots, long cushions, character heads that must stand |

| Fiber + pellets mix | Combine softness and weight | Soft body with weighted zones | Weighted animals, base-weighted plush for stable sitting |

As a buyer, you don’t need to design the stuffing plan in detail, but it helps to say things like:

- “We want very soft, squishy feel like a pillow.”

- “We want the plush to sit stable on a shelf.”

- “We want a weighted version for older kids or adults.”

This tells us how to tune stuffing type and density inside the plushie.

How do threads, trims, and accessories affect safety and durability?

Many brands focus only on fabric and stuffing, but threads, trims, and accessories are often where safety problems appear. Eyes that fall off, buttons that loosen, or weak stitching can all cause risk and complaints. Good plushies need strong “invisible” materials as well as cute visible ones.

Sewing threads and seams

We mainly use polyester sewing thread because it is:

- Strong and slightly stretchy

- Colorfast and wash-resistant

- Stable across different climates

Seam types matter too. For plushies, we commonly use:

- Lockstitch for general seams

- Overlock to prevent fraying on edges

- Bartack stitches at stress points (like arm joints or tail bases)

If thread quality or seam type is wrong, seams can open under normal play, exposing stuffing and inner parts.

Eyes, noses, and facial features

Facial features define personality but also must be safe:

- For babies and under-3 toys, we use fully embroidered faces. No hard parts.

- For older children and collectors, we may use plastic safety eyes and noses with locking washers inside the head. These must pass pull tests.

Embroidery thread needs to be soft, colorfast, and secure. The back side of embroidery should not have big knots or sharp edges that can irritate skin or snag.

Clothing, trims, and accessories

Clothing (T-shirts, hoodies, dresses, caps), ribbons, bows, and tiny props all add value and story. But they must be designed according to age grading:

- For low ages, avoid tiny buttons, beads, or loose bows.

- For higher age grading (e.g., 14+ décor or collectors), we can add more complex details, but still need solid construction.

Labels must be sewn securely and hold correct care and safety information.

Threads, trims, and accessories – impact on plushie quality

| Component | Best Practices in Production | Impact on Safety & Durability | Tips for Buyers |

|---|---|---|---|

| Sewing thread | Use toy-grade polyester thread, correct thickness and tension | Strong seams, fewer breakages, better shape | Ask which thread is used and how seams are reinforced |

| Seam construction | Lockstitch + overlock; bartacks at stress points | Resists pulling and rough play | Request seam strength testing and photos of inside seams |

| Eyes and noses | Embroidery for under-3; safety eyes/noses for 3+ with pull test | Prevent choking hazards; pass safety standards | Decide age grading early; choose style accordingly |

| Embroidery details | Toy-grade thread, controlled density, clean back side | Long-lasting details, no sharp thread ends | Approve embroidery samples on real plush fabric |

| Clothing & trims | Secure stitching; avoid small loose parts for low ages | Prevent parts from detaching or tangling | Match complexity of accessories to age grading |

| Labels & hangtags | Firmly attached, clear printing | Meet legal requirements and brand expectations | Use labels for care info, safety marks, and branding |

When you check samples, do not only look at the face and fabric. Turn the plushie around, stretch seams gently, and tug on accessories. This simple habit will tell you quickly if a manufacturer respects safety and durability.

What global safety standards regulate plushie material selection?

No matter how soft or cute a plushie is, it must also be safe. For global markets, plushies must meet strict safety standards that directly affect which materials we can use and how we use them.

Main safety frameworks

For plush toys and plushies, the key standards include:

- EN 71 (Europe)

- EN 71-1: Mechanical and physical properties

- EN 71-2: Flammability

- EN 71-3: Migration of certain elements (heavy metals)

- ASTM F963 (USA) – Toy safety standard covering mechanical, flammability, and other hazards.

- CPSIA (USA) – Covers lead content, certain phthalates, and tracking labels for children’s products.

- Other regional rules – such as UKCA in the UK, Canadian regulations, and country-specific requirements in places like Japan or the Middle East.

In addition, many buyers request textile certifications like OEKO-TEX® Standard 100 for fabrics that touch children’s skin, especially for baby products.

How these standards affect materials

These rules mean we must carefully control:

- Fabric choice – must be toy-grade, pass flammability and chemical tests.

- Dyes and prints – must be free from banned azo dyes and should not release dangerous substances.

- Stuffing cleanliness – must be clean, low-odor, and free from contaminants.

- Trims and accessories – must not break into small parts under test forces.

- Metals and coatings – must meet limits for heavy metals and certain chemicals.

A professional factory will:

- Work with trusted fabric and stuffing suppliers that provide test reports.

- Run incoming inspections to check each batch of materials.

- Send golden samples to accredited labs for full toy testing.

- Keep material records so they know exactly what went into each batch.

Global standards and their impact on plushie materials

| Standard / Area | What It Regulates | Material Impact | What you should ask for as a buyer |

|---|---|---|---|

| EN 71-1 (EU) | Mechanical and physical properties | Seam strength, small parts from trims and accessories | Ask for seam tests and small-part risk assessment |

| EN 71-2 (EU) | Flammability | Fabric must not burn too quickly | Confirm fabric is toy-grade and flammability tested |

| EN 71-3 (EU) | Migration of certain elements (heavy metals) | Dyes, prints, coatings on fabrics and trims | Request EN 71-3 reports for relevant materials |

| ASTM F963 (USA) | Toy safety (mechanical, flammability, chemicals) | Similar controls as EN 71; materials must match tests | Ensure designs can pass both EU and US tests where needed |

| CPSIA (USA) | Lead, certain phthalates, tracking labels | Affects coatings, PVC parts, and labeling | Confirm materials and prints are CPSIA-compliant |

| OEKO-TEX® Std. 100 | Human-ecological textile safety | Limits harmful substances in fabrics | Request certificates for fabrics used in baby or premium plushie lines |

Choosing materials is not just about touch and price—it is also about legal access to markets. If you plan to sell in the EU and US, it is smart to design your plushies so they can pass both EN 71 and ASTM/CPSIA with one material set.

How are sustainable and recycled materials transforming plushie production?

In the past, most plushies were made with virgin polyester fabrics and fiberfill. Today, many brands want to balance softness, safety, and cost with sustainability goals. This is changing which materials we choose and how we talk about them.

Recycled polyester fabrics and stuffing

The most practical and scalable change is moving from virgin polyester to recycled polyester (rPET) in:

- Outer plush fabrics (minky, short plush, sometimes faux fur)

- Inner stuffing (rPET fiberfill)

Good rPET materials can match the softness and performance of traditional plush while reducing use of new fossil-based plastic. To support serious claims, we look for:

- GRS (Global Recycled Standard) or similar certifications

- Clear documentation of recycled content percentage

With this, brands can honestly say things like:

- “Fabric and stuffing made with recycled polyester”

- “Contains xx% recycled content”

Natural and organic fabrics in plushies

Some plushies use organic cotton, bamboo viscose, or other eco-textiles for:

- Baby comforters and flat plush

- Clothing on plushies

- Patch panels or mixed-material designs

These fibers can support a natural, skin-friendly message, but they require extra testing for:

- Shrinkage after washing

- Colorfastness to saliva, sweat, and wash

- Pilling and surface wear

They are often used together with synthetic plush, not as a full replacement, to keep softness and durability.

Eco-minded trims, labels, and packaging

Sustainability is not only inside the plushie. Many brands also adjust:

- Labels and hangtags – recycled polyester labels, recycled paper hangtags, soy inks.

- Plastic reduction – less or no single-use plastic where possible.

- Cartons – FSC-certified or recycled corrugated boxes.

These changes are simpler to implement and still send a strong message to end customers and retail partners.

Honest communication

The most important rule: eco claims must be honest and backed by evidence. Customers and retailers are more careful now. If you claim “eco plush” but cannot provide any real proof, you risk losing trust.

Sustainable and recycled material options for plushies

| Area | Eco Option | Benefits | Considerations |

|---|---|---|---|

| Outer plush fabric | rPET minky / short plush / faux fur | Reduces virgin polyester usage; keeps softness | Needs certified supply; quality and hand-feel must be tested |

| Stuffing | rPET polyester fiberfill | Similar hug feel as standard fiberfill | Verify cleanliness, loft, and odor; align with lab testing |

| Baby-contact zones | Organic cotton knit/terry, bamboo viscose | Natural feel, strong story for baby ranges | Extra tests for shrinkage, colorfastness, and pilling |

| Trims & labels | Recycled polyester labels, recycled hangtags | Visible eco detail, easy to communicate | Ensure printing remains clear and durable |

| Packaging | FSC or recycled cartons, reduced plastic | Supports retailer and brand sustainability goals | Balance between product protection and material reduction |

| Communication | Clear recycled content claims, real certificates | Builds trust and long-term brand value | Avoid vague terms like “green” without specifics or proof |

At Kinwin, we often start with small eco steps—for example, shifting stuffing to rPET while keeping tried-and-tested fabrics, then gradually moving to rPET plush once the brand is comfortable with performance and cost.

Conclusion

A good plush toy is safe, soft, durable, and appealing while also offering branding opportunities. The materials behind a plushie—fabrics, stuffing, threads, trims, and labels—decide not only how it feels in the hand but also how it passes safety tests, supports sustainability goals, and represents your brand.

At Kinwin, we help global buyers choose and control plushie materials that fit their target market, budget, safety requirements, and eco ambitions. From standard polyester plush to recycled fabrics and rPET stuffing, my team can guide you from material selection to final shipment. Contact us at [email protected] or visit kinwintoys.com to discuss your next plush project and explore how our factory can support your success.