Verifying a stuffed animal manufacturer’s quality and compliance is one of the most critical steps in protecting your brand, your customers, and your long-term business growth. From my experience working with international buyers, most sourcing problems do not come from price—but from weak systems, unclear standards, and unverified claims.

A professional manufacturer should be able to demonstrate how quality and compliance are built into daily operations, not just shown through certificates or sales presentations. This article breaks down how buyers can verify these capabilities step by step, starting with the foundation: quality management systems.

What Quality Management Systems Indicate a Reliable Stuffed Animal Manufacturer?

A reliable stuffed animal manufacturer is defined less by promises and more by how its quality management system operates every day. Strong factories rely on structured processes that prevent defects instead of reacting to them after production.

The first system to examine is Incoming Quality Control (IQC). This determines how fabrics, fillings, accessories, threads, and packaging are inspected before entering production. A serious factory will have written inspection standards, sampling ratios, defect classification, and supplier rejection procedures. If raw materials are not controlled, final product quality becomes unpredictable.

Next is In-Process Quality Control (IPQC). During sewing, stuffing, embroidery, and assembly, inspectors should check seam strength, stitch density, symmetry, filling weight, and attachment security. IPQC is especially critical for stuffed animals because most safety risks—loose parts, weak seams, incorrect filling—originate during production, not at the final stage.

Final Quality Control (FQC) and Outgoing Quality Control (OQC) confirm that finished stuffed animals meet approved samples, packing requirements, and labeling rules. Factories with mature systems use AQL standards, maintain inspection records, and separate non-conforming goods instead of mixing them into shipments.

Beyond inspection points, look for documentation discipline. Quality manuals, SOPs, inspection records, corrective action reports, and defect trend analysis indicate that quality is managed systematically, not emotionally.

| Quality System Area | What Buyers Should Verify | Why It Matters |

|---|---|---|

| IQC | Material inspection standards & records | Prevents defects at source |

| IPQC | In-line inspection checkpoints | Controls sewing & safety risks |

| FQC / OQC | AQL-based final inspections | Ensures shipment consistency |

| Documentation | SOPs, QC logs, CAPA reports | Shows process maturity |

| Responsibility | Dedicated QC team, not shared roles | Avoids conflict of interest |

When these systems are clearly defined, consistently executed, and traceable with records, the factory is far more likely to deliver stable quality across repeated orders, not just a good first sample.

How Can Buyers Assess Safety Standards and Compliance for Target Markets?

Assessing safety standards and compliance is where many buyers make costly assumptions. A stuffed animal that looks well-made can still fail market access if it does not meet region-specific safety regulations. From my experience, professional buyers always evaluate compliance by target market, not by generic claims like “we follow international standards.”

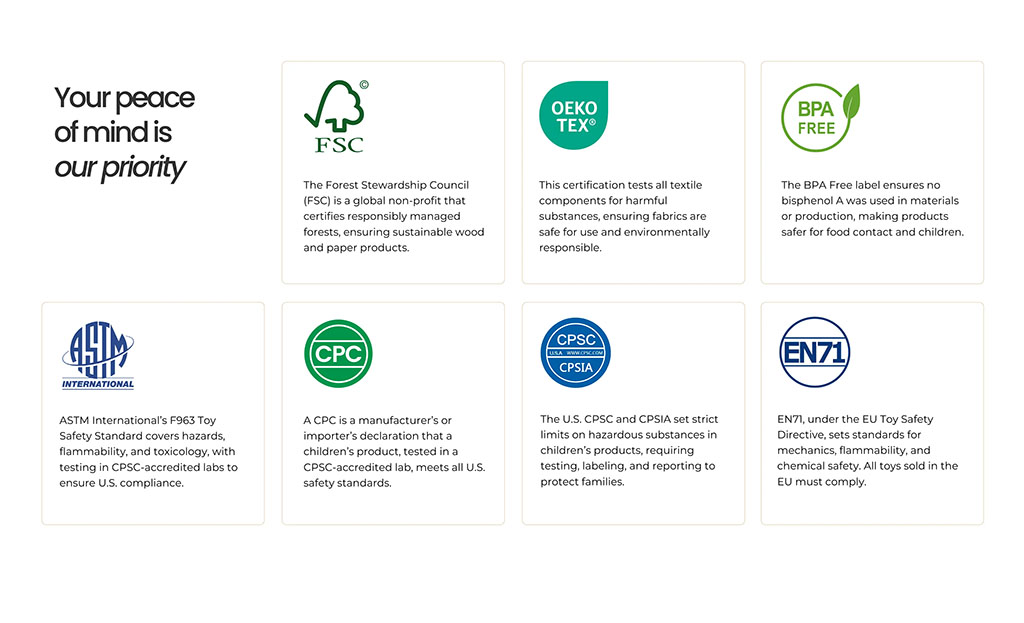

The first step is to confirm which markets the factory regularly serves. A manufacturer exporting mainly to the U.S. should be deeply familiar with ASTM F963, CPSIA, CPC documentation, and CPSC-accepted lab testing. A factory focused on Europe should clearly understand EN71 parts 1–3, REACH chemical limits, and CE technical documentation. Factories serving Japan or Korea should reference ST standards or KC requirements. Real compliance shows in how confidently and precisely these standards are explained.

Next, review how safety is built into design and material selection, not just tested at the end. Ask how the factory evaluates choking hazards, seam strength, attachment security, and filling accessibility during pattern making and sampling. A strong manufacturer can explain how age grading affects eye types, embroidery choices, and internal construction.

Chemical safety is another critical area. Buyers should ask how dyes, prints, fillings, and accessories are screened for restricted substances such as lead, phthalates, formaldehyde, and azo dyes. Factories with mature systems maintain approved material lists and require supplier test reports before use.

Finally, assess how compliance is maintained across production, not just for one sample. Ask how design changes, supplier substitutions, or process adjustments trigger re-evaluation. Factories that treat compliance seriously have internal checkpoints to prevent unapproved changes from entering mass production.

| Compliance Area | What Buyers Should Check | Risk If Ignored |

|---|---|---|

| Target market standards | ASTM, EN71, CPSIA, REACH, etc. | Shipment rejection |

| Age grading control | Design rules by age group | Choking hazards |

| Chemical safety | Material screening & test data | Legal violations |

| Design-stage safety | Built-in safety review | Late-stage failures |

| Change management | Re-checks after revisions | Inconsistent compliance |

When a factory can clearly explain how it manages safety before, during, and after production, buyers gain confidence that compliance is not accidental—it is systematic and repeatable.

What Certifications and Test Reports Should Be Verified Before Production?

Before any stuffed animal enters mass production, buyers should verify certifications and test reports as evidence of capability, not as marketing decoration. From my experience, the key is to distinguish between factory-level certifications (which reflect system control) and product-level test reports (which confirm item-specific compliance).

Start with factory certifications. Standards such as ISO 9001 indicate structured quality management, while BSCI, SMETA, or Sedex reports show social compliance and ethical labor practices. These do not replace product testing, but they signal whether a factory operates with discipline and accountability. Ask for the latest audit dates, scope, and corrective action status—outdated or partial audits reduce their value.

Next, verify material and component certifications. For stuffed animals, this often includes OEKO-TEX for fabrics, GRS for recycled fillings, and supplier test reports for dyes, prints, and accessories. These documents reduce chemical risk before a single unit is produced.

Most critical are product-level safety test reports relevant to your target market. For the U.S., confirm ASTM F963 and CPSIA (including lead and phthalates). For the EU, request EN71-1/2/3 and REACH SVHC screening. Ensure reports are issued by accredited, market-accepted laboratories and match the actual construction, materials, and age grading of your product.

Finally, check timing and linkage. Test reports must align with the approved sample version and remain valid through production. Any design or material change after testing should trigger re-testing.

| Document Type | What to Verify | Why It Matters |

|---|---|---|

| Factory certifications | Valid scope, recent audit | Shows system maturity |

| Material certificates | Fabric/filling compliance | Prevents chemical risk |

| Product test reports | Correct standards & labs | Market access approval |

| Report validity | Dates & sample linkage | Avoids invalid tests |

| Change control | Re-test triggers defined | Maintains compliance |

When certifications and reports are verified early—and tied tightly to samples and specs—buyers prevent last-minute failures, shipment delays, and costly rework. This discipline sets the foundation for predictable, compliant production.

What Certifications and Test Reports Should Be Verified Before Production?

Before any stuffed animal enters mass production, buyers should verify certifications and test reports as evidence of capability, not as marketing decoration. From my experience, the key is to distinguish between factory-level certifications (which reflect system control) and product-level test reports (which confirm item-specific compliance).

Start with factory certifications. Standards such as ISO 9001 indicate structured quality management, while BSCI, SMETA, or Sedex reports show social compliance and ethical labor practices. These do not replace product testing, but they signal whether a factory operates with discipline and accountability. Ask for the latest audit dates, scope, and corrective action status—outdated or partial audits reduce their value.

Next, verify material and component certifications. For stuffed animals, this often includes OEKO-TEX for fabrics, GRS for recycled fillings, and supplier test reports for dyes, prints, and accessories. These documents reduce chemical risk before a single unit is produced.

Most critical are product-level safety test reports relevant to your target market. For the U.S., confirm ASTM F963 and CPSIA (including lead and phthalates). For the EU, request EN71-1/2/3 and REACH SVHC screening. Ensure reports are issued by accredited, market-accepted laboratories and match the actual construction, materials, and age grading of your product.

Finally, check timing and linkage. Test reports must align with the approved sample version and remain valid through production. Any design or material change after testing should trigger re-testing.

| Document Type | What to Verify | Why It Matters |

|---|---|---|

| Factory certifications | Valid scope, recent audit | Shows system maturity |

| Material certificates | Fabric/filling compliance | Prevents chemical risk |

| Product test reports | Correct standards & labs | Market access approval |

| Report validity | Dates & sample linkage | Avoids invalid tests |

| Change control | Re-test triggers defined | Maintains compliance |

When certifications and reports are verified early—and tied tightly to samples and specs—buyers prevent last-minute failures, shipment delays, and costly rework. This discipline sets the foundation for predictable, compliant production.

How Can On-Site Audits and Third-Party Inspections Validate Manufacturer Claims?

On-site audits and third-party inspections are the most effective ways to separate real capability from well-prepared presentations. While documents and samples are important, audits reveal whether quality and compliance are consistently executed under normal production conditions.

On-site factory audits allow buyers to verify claims about production scale, QC discipline, and compliance culture. During an audit, focus on how procedures are actually followed on the floor—not just what is written in manuals. For example, check whether IQC records match incoming materials, whether IPQC inspections occur at defined stations, and whether non-conforming goods are physically segregated. Consistency between policy and practice is the key signal of reliability.

Process audits are especially valuable for stuffed animals because risks are often process-driven. Auditors should examine seam strength control, attachment methods for eyes and accessories, stuffing density controls, and needle management systems. A factory that can explain why a control exists (not just that it exists) demonstrates true operational understanding.

Third-party inspections—such as pre-production checks, DUPRO (during production) inspections, and pre-shipment inspections—add independent verification. Using internationally recognized inspection companies reduces bias and provides standardized reporting. These inspections should be aligned with AQL levels, safety checkpoints, and your approved PPS.

Finally, assess how the factory responds to audit findings. Professional manufacturers treat findings as improvement inputs, issuing corrective and preventive actions (CAPA) with timelines and responsible owners. Defensive attitudes or superficial fixes are warning signs.

| Verification Method | What Buyers Should Validate | Why It’s Critical |

|---|---|---|

| On-site audits | Practice matches procedures | Confirms execution |

| Process review | Sewing, stuffing, attachments | Identifies safety risks |

| Third-party inspections | AQL, PPS alignment | Independent assurance |

| Reporting quality | Clear photos & data | Actionable decisions |

| CAPA response | Root cause & follow-up | Long-term improvement |

When audits and inspections are planned as part of an ongoing quality strategy—not a one-time hurdle—they provide buyers with continuous visibility and control, greatly reducing compliance and shipment risks.

How Does Ongoing Quality Monitoring Ensure Long-Term Compliance and Consistency?

Ongoing quality monitoring is what transforms a one-time compliant shipment into a stable, repeatable supply relationship. Even strong factories can drift without continuous oversight—materials change, staff turnover happens, and processes evolve. Buyers who maintain visibility and controls over time are far more likely to receive consistent quality and avoid sudden compliance failures.

Effective monitoring starts with defined quality KPIs agreed by both sides. These typically include defect rates by category (sewing, stuffing, appearance, safety), rework percentages, on-time delivery, and test pass rates. When KPIs are reviewed regularly, issues are identified early—before they escalate into shipment delays or recalls.

Next is change management discipline. Any modification to materials, suppliers, construction methods, or tooling should trigger a formal review. Professional factories log changes, assess risk, and—when required—conduct partial or full re-testing. Buyers should require written notification and approval for changes that could affect safety or compliance.

Regular periodic inspections and audits reinforce standards. This may include scheduled third-party inspections, annual factory audits, or rotating spot checks. The goal is not policing, but verification that systems still function as designed. Factories that welcome these checks typically operate with confidence in their processes.

Finally, strong partnerships use data-driven feedback loops. Defect trends are analyzed, root causes identified, and corrective actions tracked to closure. Over time, this approach reduces variation, lowers cost of quality, and builds trust on both sides.

| Monitoring Area | Ongoing Practice | Long-Term Benefit |

|---|---|---|

| Quality KPIs | Regular performance reviews | Predictable outcomes |

| Change control | Formal approval & re-testing | Compliance stability |

| Periodic inspections | Scheduled & spot checks | Early risk detection |

| Data analysis | Trend & root-cause review | Continuous improvement |

| Collaboration | Shared improvement plans | Strong partnership |

When ongoing monitoring is embedded into the relationship, quality and compliance become managed processes, not assumptions—supporting scalable growth and reliable market access.

Conclusion

Verifying a stuffed animal manufacturer’s quality and compliance requires more than certificates or attractive samples—it demands a structured evaluation of systems, evidence, and execution. By reviewing quality management systems, market-specific safety controls, certifications, sampling discipline, audits, and ongoing monitoring, buyers can confidently identify partners capable of delivering compliant, consistent products over time. This approach reduces risk, protects brand reputation, and supports sustainable, long-term sourcing success.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com