One of the most common questions brands ask is:

“Why is the price of custom plush toys different from one supplier to another?”

Custom plush pricing is not random. It is influenced by structure, materials, features, order volume, development effort, and logistics decisions. If these factors are clearly understood, pricing becomes predictable and easier to control.

In this guide, I’ll break down the key elements that influence custom plush toy cost—so you can plan your project with clarity and confidence.

Let’s begin with one of the biggest cost drivers: size and structure.

How Do Size and Structural Complexity Influence Plush Toy Costs?

Size and structural design are among the most direct cost drivers in plush toy manufacturing. A 20cm plush is not simply twice the cost of a 10cm plush. Cost increases are influenced by material usage, labor time, and construction difficulty.

First, size directly affects material consumption.

Larger plush toys require more fabric, more filling, and often stronger stitching to maintain shape. Fabric is usually priced per meter, so increased surface area raises raw material cost.

Second, larger size increases stuffing cost and shipping weight.

More filling means higher internal material usage. Heavier products also increase freight cost per unit.

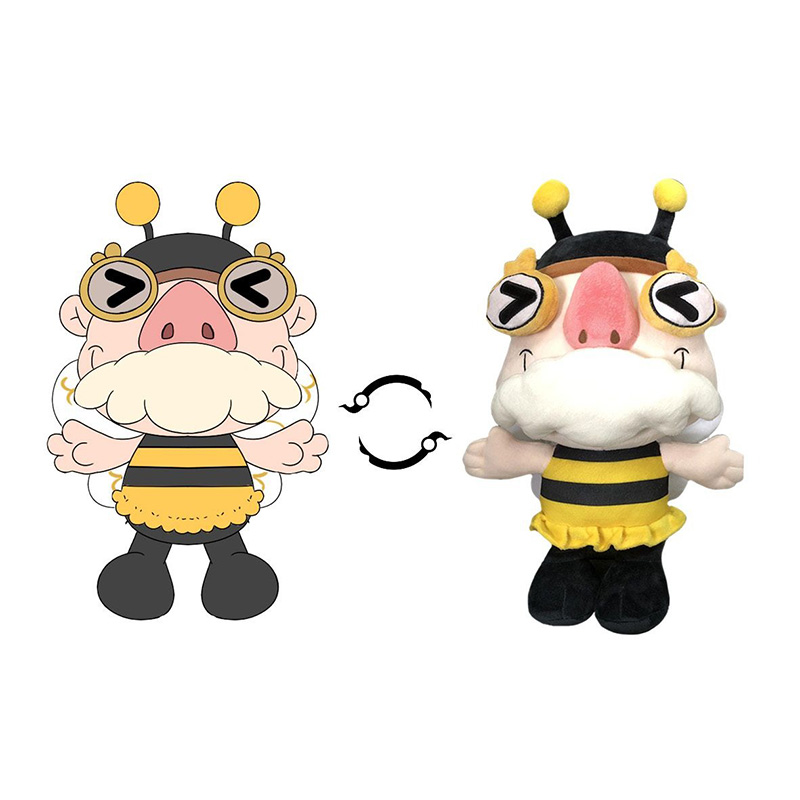

Third, structural complexity impacts labor time.

A simple plush with minimal panels is faster to sew. But a plush with multiple body sections, layered components, or sculpted shaping requires more cutting, sewing, and assembly time.

Fourth, complex shapes require more pattern development.

Curved heads, 3D noses, shaped limbs, or multi-panel bodies demand more advanced pattern making and more testing during sampling.

Fifth, stability features add cost.

If a plush needs to sit upright or hold a specific posture, internal weight bags or structural support may be added.

Here is a simplified cost impact overview:

| Cost Factor | Simple Design | Complex Design | Cost Impact |

|---|---|---|---|

| Size | Small (15cm) | Large (35cm) | Higher fabric & stuffing |

| Panel count | Few panels | Many panels | Increased labor |

| Shape | Basic round | Sculpted 3D | Higher pattern cost |

| Internal support | None | Weighted / structured | Added material |

| Sewing time | Short | Longer | Labor increase |

For buyers, this means pricing discussions should not focus only on “size.” Structure matters just as much.

At Kinwin, when clients request quotations, we review size, panel count, and internal structure together before estimating price. This ensures pricing reflects real production effort—not guesswork.

Understanding how size and complexity influence cost helps brands optimize design early and control budget without sacrificing product appeal.

What Role Do Fabric Type and Material Selection Play in Pricing?

After size and structure, fabric selection is usually the second largest cost driver in custom plush production. Many buyers focus only on color, but fabric type directly affects both material cost and manufacturing complexity.

Not all plush fabrics are priced the same.

First, pile length and density matter.

Short-pile fabrics such as velboa are generally more cost-efficient. Long-pile or faux fur fabrics use more fiber and require more finishing processes, which increases price.

Second, fabric quality grade influences cost.

Higher-density backing, stronger weave, and softer surface textures cost more but improve durability and appearance.

Third, specialty fabrics increase sourcing cost.

Organic cotton, RPET recycled polyester, or specialty dyed fabrics often carry premium pricing due to certification and limited supply.

Fourth, color customization adds expense.

If your brand requires a custom-dyed Pantone color instead of stock fabric, dye lot production minimums apply, increasing material cost.

Fifth, multi-fabric designs increase complexity.

Using several fabric types in one plush increases cutting time, panel matching, and sewing difficulty.

Here is how fabric choice influences cost:

| Fabric Type | Cost Level | Why |

|---|---|---|

| Velboa | Lower | Efficient production, stable texture |

| Minky | Medium | Softer feel, slightly higher fiber density |

| Faux Fur | Higher | Long pile, more processing |

| Organic Cotton | Higher | Certified sourcing cost |

| RPET Fabric | Higher | Recycled material premium |

| Custom Dyed Fabric | Higher | Dye lot minimum requirement |

Beyond outer fabric, internal materials also matter.

Filling materials vary in cost depending on:

- Fiber grade

- Resilience level

- Certification requirements

Higher-grade fiber maintains shape longer but costs more than basic polyester filling.

For brands targeting premium markets, investing in better fabric improves hand feel and customer perception. For promotional projects, selecting cost-efficient fabric may optimize budget.

At Kinwin, we often provide fabric recommendations based on your target market and price positioning. This helps balance appearance, durability, and cost efficiency before production begins.

Understanding material selection early prevents unexpected budget increases later.

How Do Custom Features Such as Embroidery and Accessories Add to Cost?

Once size and fabric are defined, the next major pricing factor is customization. The more unique the design features, the more production steps are required. Each additional detail increases labor time, material cost, or machine setup.

Many brands want their plush toy to stand out. That’s a good strategy—but it’s important to understand how these custom elements influence price.

First, embroidery complexity affects cost.

Embroidery pricing is usually based on stitch count. A small, simple logo may require only a few thousand stitches. A detailed face or multi-color design can require tens of thousands of stitches, increasing machine time and thread usage.

Second, color changes in embroidery add setup time.

Each thread color change requires machine adjustment. More color layers mean longer production cycles.

Third, printing adds process steps.

Screen printing, heat transfer printing, or digital printing each require separate production procedures. Placement accuracy and drying time also affect labor cost.

Fourth, accessories increase assembly time.

Hats, scarves, clothing, ribbons, bags, or attached tags require additional sewing and inspection steps.

Fifth, plastic components or safety eyes influence compliance cost.

If hard accessories are used, additional safety testing may be required, especially for children’s markets.

Sixth, sound modules or interactive features significantly increase cost.

Electronic components, battery compartments, and assembly time add both material and labor expense.

Here’s a simplified view of how custom features impact pricing:

| Custom Feature | Cost Impact Level | Why |

|---|---|---|

| Simple embroidery | Low | Minimal stitch count |

| Detailed embroidery | Medium–High | Higher stitch density |

| Multi-color embroidery | Higher | Machine color changes |

| Screen printing | Medium | Additional process step |

| Clothing / accessories | Medium–High | Extra sewing time |

| Plastic parts | Medium | Compliance testing |

| Sound modules | High | Electronics & assembly |

For buyers, the key is prioritization.

Ask yourself:

- Which design elements are essential for brand identity?

- Which features add emotional value?

- Which details may not justify the added cost?

At Kinwin, we help clients evaluate feature impact early during quotation. Sometimes a small design adjustment—like simplifying embroidery density or combining fabric panels—can reduce cost significantly without affecting brand appeal.

Custom features are powerful tools for differentiation. But controlling feature complexity helps keep pricing within target margins.

How Do Order Quantity and MOQ Impact Unit Price?

One of the biggest misunderstandings in plush toy pricing is this:

“Why is the unit price so much higher for small orders?”

The answer lies in cost distribution.

Custom plush manufacturing includes both fixed costs and variable costs. When order quantity increases, fixed costs are spread across more units—reducing the unit price.

Here’s how order quantity affects pricing:

First, material purchasing efficiency.

Fabric mills and filling suppliers often have minimum order quantities. Larger plush orders allow factories to purchase materials more efficiently, reducing per-unit cost.

Second, machine setup cost distribution.

Embroidery machines, printing setups, and cutting templates require preparation time. Whether you produce 300 pieces or 5,000 pieces, setup time is similar. Larger orders reduce the setup cost per unit.

Third, labor efficiency improves with scale.

Production lines operate more smoothly when running continuous large batches. Frequent stop-and-start small runs increase inefficiency.

Fourth, packaging and labeling economies.

Bulk printing of tags, labels, and packaging reduces cost per piece.

Fifth, shipping optimization.

Larger quantities allow better container utilization, lowering freight cost per unit.

Here’s a simplified cost comparison example:

| Order Quantity | Fixed Cost Distribution | Estimated Unit Price Trend |

|---|---|---|

| 300 pcs | High per unit | Higher |

| 500 pcs | Moderate | Medium |

| 1,000 pcs | Lower | More competitive |

| 3,000+ pcs | Efficient | Best unit cost |

MOQ (Minimum Order Quantity) exists because factories must maintain production efficiency and material purchasing practicality.

However, MOQ can sometimes be flexible depending on:

- Fabric stock availability

- Simplicity of design

- Existing production schedule

- Long-term partnership potential

At Kinwin, we discuss MOQ based on real production feasibility rather than rigid policy. For growing brands, we often help balance lower MOQs with realistic pricing structures.

For buyers, understanding the relationship between volume and cost helps with planning. If your goal is to reduce unit price, increasing order volume is often more effective than negotiating aggressively.

Scaling smartly is usually the best pricing strategy.

What Sampling, Development, and Mold Fees Should Be Considered?

When discussing plush pricing, many buyers focus only on unit price. But custom plush projects also include upfront development costs that should be clearly understood before starting.

These costs are not hidden charges. They reflect the real work required to transform an idea into a manufacturable product.

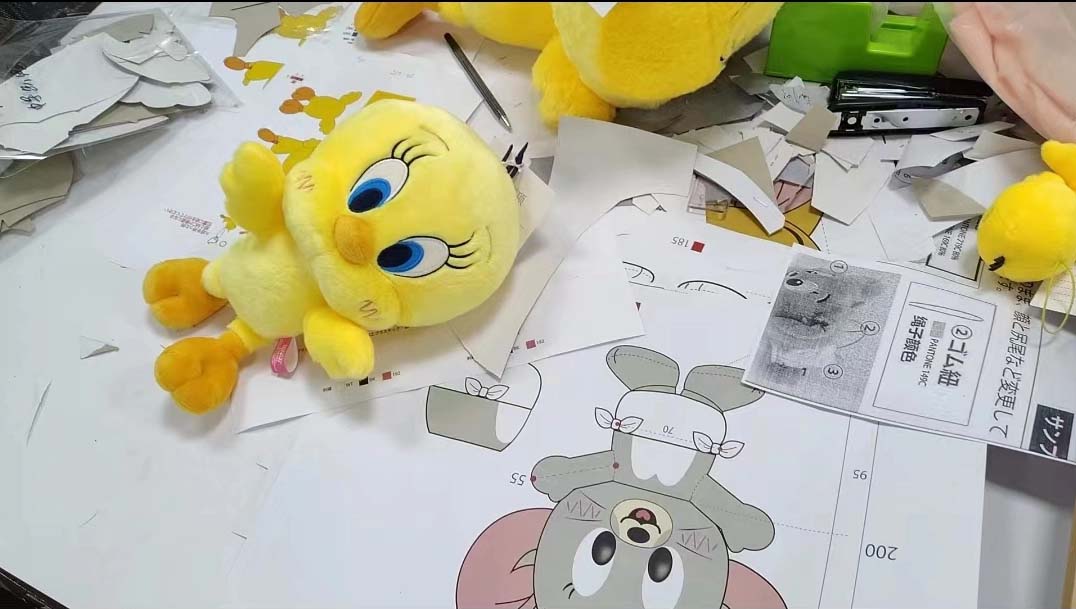

First, sampling fees.

Sampling includes:

- Pattern development

- First prototype sewing

- Material testing

- Internal structure adjustment

- Embroidery file programming

Sampling requires skilled pattern makers and multiple test adjustments. This is labor-intensive work, especially for new designs.

Sampling fees vary depending on:

- Design complexity

- Number of panels

- Custom embroidery requirements

- Special structure or accessories

Second, development and pattern fees.

For highly complex designs, pattern development may require:

- Multiple rounds of 3D adjustments

- Structural reinforcement testing

- Balance and posture correction

Some factories separate pattern development fees from sample sewing fees, especially for advanced projects.

Third, embroidery digitizing fees.

Before embroidery begins, artwork must be converted into machine-readable stitch files. Detailed logos or character faces require professional digitizing, which adds cost.

Fourth, mold or tool fees (when applicable).

Most plush toys do not require molds. However, if your design includes:

- Plastic safety eyes with custom shapes

- Silicone parts

- Custom injection-molded accessories

Then tooling or mold fees may apply. These are usually one-time costs for creating production tools.

Here’s a simplified overview:

| Development Element | When It Applies | Cost Type |

|---|---|---|

| Basic sample fee | Standard plush | One-time |

| Complex pattern development | Sculpted 3D design | One-time |

| Embroidery digitizing | Custom logo/face | One-time |

| Mold/tooling fee | Plastic or silicone parts | One-time |

| Revision rounds | Major design changes | Additional |

In many cases, sampling fees are partially refundable once bulk orders reach a certain volume. Policies vary by factory.

At Kinwin, we clearly break down sampling and development costs before starting. If bulk orders proceed, we often offset or credit part of the sample fee depending on volume.

For buyers, development fees should be viewed as an investment in precision and accuracy. A well-developed prototype reduces production errors and long-term cost risks.

Understanding upfront development costs prevents misunderstandings later in the process.

How Do Packaging, Testing, and Logistics Affect Total Landed Cost?

Many buyers compare factory unit prices without calculating the total landed cost. But in reality, packaging, compliance testing, and logistics can significantly affect the final cost per piece.

Understanding these hidden or indirect costs helps brands avoid budget surprises.

First, packaging choices directly impact cost.

Basic packaging (such as polybag + care label) keeps cost low.

Retail-ready packaging (color box, window box, custom hangtag, barcode label, inner tray) increases material and assembly cost.

Special packaging like vacuum packing may reduce shipping cost by lowering volume, but it adds handling steps.

Second, safety testing and certification fees.

If your plush toy is entering markets like the U.S. or EU, third-party testing is often required. This may include:

- CPSIA testing (U.S.)

- EN71 testing (EU)

- ASTM compliance

- Chemical and flammability tests

Testing fees depend on:

- Number of materials used

- Whether previous reports can be reused

- Market-specific requirements

For highly customized designs with multiple fabrics and accessories, testing cost may increase.

Third, freight cost and shipping method.

Freight cost depends on:

- Shipment volume (CBM)

- Gross weight

- Shipping method (sea, air, express)

- Destination country

Larger plush toys increase volume cost significantly. Even if material cost is moderate, high shipping volume can increase landed cost.

Fourth, import duties and taxes.

Depending on your country, customs duties may apply. Plush toys usually fall under specific HS codes, and duty rates vary by region.

Here’s a simplified cost structure overview:

| Cost Category | Low-Cost Option | Higher-Cost Option | Impact |

|---|---|---|---|

| Packaging | Polybag | Retail color box | Increased material & labor |

| Testing | Existing reports | New multi-material testing | Certification expense |

| Shipping | Sea freight | Air freight | Freight multiplier |

| Volume size | Small plush | Large plush | Higher CBM cost |

| Accessories | Minimal | Multi-component | Higher inspection & testing |

For buyers, total landed cost =

Unit manufacturing cost + packaging + testing + freight + duties.

At Kinwin, we discuss packaging plans, testing requirements, and freight estimates during quotation stage, so clients can see the full picture—not just factory price.

Transparent cost planning leads to better profit planning.

Conclusion

Custom plush toy pricing is influenced by multiple factors—size, structure, materials, customization features, order quantity, development effort, packaging, compliance testing, and logistics.

When these elements are clearly defined early, pricing becomes predictable and manageable.

Instead of asking only “What is the unit price?”, a better question is:

“How is the total cost structured, and where can we optimize without reducing quality?”

If you are planning a custom plush project and want a clear, structured quotation breakdown, our team at Kinwin is ready to support you.

Contact: [email protected]

Visit: https://kinwintoys.com