Choosing a teddy bear manufacturer in China is not just about finding a factory that can sew plush. From my experience working with brand owners, retailers, and wholesale buyers, teddy bears are a special category because buyers expect stable face expression, consistent hand-feel, and long-term repeatability. A factory that performs well on general plush may still struggle with teddy bear details, especially when you scale into large orders.

Teddy bears also carry higher emotional value than many other plush items. Small differences in fur texture, nose placement, or stuffing balance can change how “premium” or “cheap” a bear feels. That directly affects retail positioning, customer reviews, and reorder confidence.

Before comparing prices or requesting samples, the first thing buyers should confirm is simple: does the factory have the right experience and specialization for teddy bear production, not just “plush toys” in general?

What Manufacturing Experience and Teddy Bear Specialization Should Buyers Look For?

When I evaluate teddy bear manufacturers, I never start with equipment lists. I start with category specialization, because teddy bears require a combination of soft material control, precise pattern balance, and consistent finishing that many general plush factories do not master.

The first thing to look for is teddy bear-specific production experience, not just years in business. A factory might claim 10–15 years of manufacturing history but produce mostly promotional plush, keychains, or simple shapes. Teddy bears often involve longer-pile fabrics, more visible seam lines, stricter symmetry expectations, and higher consumer sensitivity to touch. A factory that produces teddy bears regularly will understand these demands naturally.

Next, buyers should check whether the factory has handled different teddy bear styles, because each style stresses different skills. For example, a classic jointed teddy bear requires stronger seam reinforcement and precise limb alignment. A baby-safe teddy bear requires stronger small-part control and safer facial design (often embroidered). A premium gift teddy bear often needs higher-grade fabric, cleaner finishing, and better packaging readiness. If a factory only knows one teddy bear style, it may struggle when your market requirements change.

Another important indicator is whether the factory has experience with repeat programs. Teddy bears often become long-term SKUs for brands and retailers. If a manufacturer cannot reproduce the same look and hand-feel across seasons and dye lots, you will face reorder risk. Factories with repeat teddy bear programs usually have better material tracking, reference sample control, and stable workmanship.

Finally, a strong teddy bear manufacturer should be able to explain how they control teddy bear “feel”. Hand-feel is not subjective in professional production. It comes from consistent fabric selection, controlled pile direction, stuffing density, and finishing steps such as brushing and lint removal. Factories that can explain these controls clearly are usually the ones that deliver stable teddy bear quality.

| Specialization Signal | Weak Manufacturer Pattern | Strong Teddy Bear Manufacturer Pattern | Buyer Benefit |

|---|---|---|---|

| Category focus | Makes many unrelated products | Teddy bear is a core category | Higher consistency |

| Style coverage | Only simple plush shapes | Classic, baby-safe, premium bears | Better market fit |

| Repeat order experience | One-off projects | Long-term teddy bear programs | Stable reorders |

| Material handling | Generic fabric sourcing | Pile direction & batch control | Premium hand-feel |

| Quality mindset | “Looks similar” approach | Expression & symmetry control | Better retail acceptance |

For buyers, teddy bear specialization is the foundation of everything else—sampling, QC, lead time, and pricing. If a factory is not truly experienced in teddy bear production, you may still get a “nice first sample,” but bulk orders often show drift in face consistency, fabric feel, and finishing quality. A specialized teddy bear manufacturer reduces this risk from the start.

How Do Design, Pattern Making, and Sampling Skills Affect Teddy Bear Quality?

In teddy bear manufacturing, design and pattern making determine quality long before sewing begins. From my experience, many teddy bear quality issues—crooked faces, uneven arms, unstable sitting posture—are not sewing problems. They are pattern and structural design problems.

Teddy bears are structurally deceptive. They look simple, but they rely heavily on balance and symmetry. The head-to-body ratio, limb length, neck angle, and even ear position influence how friendly, premium, or childish a teddy bear feels. Factories with weak design interpretation often copy artwork visually without understanding three-dimensional balance, leading to samples that look acceptable in photos but feel wrong in hand.

Professional teddy bear factories approach design translation systematically. They break the bear into functional zones—head volume, shoulder slope, torso depth, limb rotation—and design patterns to support these volumes naturally. This is especially important when using longer-pile fabrics, where small pattern errors are magnified after stuffing and brushing.

Pattern making skill directly affects facial consistency. In teddy bears, eyes and nose placement tolerance is extremely small. A few millimeters off can change expression entirely. Skilled pattern teams design face panels that lock feature positions structurally, instead of relying on manual adjustment during sewing.

Sampling skill is the final proof of design capability. Strong factories use sampling to validate structure, not just appearance. They test stuffing density, joint movement (if applicable), and posture stability. More importantly, they document pattern revisions after each sample, ensuring that improvements are repeatable—not accidental.

Another key indicator is sample convergence speed. Experienced teddy bear manufacturers usually achieve acceptable accuracy within fewer revisions because their initial pattern logic is sound. Factories that need many rounds of correction often lack deep teddy bear design experience.

| Capability Area | Weak Factory Behavior | Strong Teddy Bear Factory Behavior | Quality Impact |

|---|---|---|---|

| Design translation | Visual copying | 3D balance interpretation | Natural proportions |

| Pattern logic | Flat pattern tracing | Volume-based patterning | Stable structure |

| Facial construction | Manual adjustment | Pattern-locked positioning | Consistent expression |

| Sampling purpose | “Looks OK” approval | Structural validation | Long-term stability |

| Revision handling | Trial-and-error | Documented pattern updates | Repeatable quality |

For buyers, design and pattern capability is where teddy bear quality is truly decided. Factories that invest in experienced pattern makers, structured sampling logic, and documented revisions are far more likely to deliver teddy bears that look consistent, feel premium, and remain stable across large production runs.

What Quality Control Systems Ensure Consistency in Large Teddy Bear Orders?

When teddy bear orders scale from samples to thousands of units, quality control becomes the deciding factor between a successful repeat program and a costly correction cycle. From my experience, teddy bears expose QC weaknesses faster than many other plush categories because small inconsistencies are immediately visible and tactile.

The first requirement is a locked reference system. Professional factories treat the approved sample as a physical standard, not just a photo. This reference is used at every stage—from cutting and sewing to stuffing and finishing. Factories that rely only on pictures or written notes often drift over time, especially across multiple production lines.

Incoming material inspection (IQC) is especially critical for teddy bears. Fabric pile length, density, color tone, and backing stability must be consistent. Even slight differences between fabric batches can change hand-feel and appearance. Strong factories record fabric batch data and reject materials that fall outside approved ranges.

In-process quality control (IPQC) is where teddy bear consistency is protected. QC teams check seam alignment, limb symmetry, facial placement, and stuffing balance during production—not only at the end. This prevents errors from multiplying across hundreds of units before detection.

Final quality control (FQC) focuses on overall expression and feel, not just defects. Teddy bears are emotional products. Professional QC includes squeeze tests, posture checks, and visual comparison against the reference sample. Bears that technically pass sewing standards may still fail emotional consistency checks.

Another key system is line-to-line consistency control. In large orders, production often runs across multiple lines. Factories with strong QC rotate inspectors, standardize work instructions, and cross-check outputs to ensure one line does not produce “a different bear” from another.

| QC System Area | Weak Factory Practice | Strong Teddy Bear QC Practice | Buyer Benefit |

|---|---|---|---|

| Reference control | Photos only | Physical approved sample | Visual stability |

| Material inspection | Basic color check | Pile & density control | Consistent hand-feel |

| In-process QC | End-of-line only | Stage-by-stage checks | Early error prevention |

| Final inspection | Defect-focused | Expression & feel checks | Retail acceptance |

| Multi-line control | Line-by-line variation | Cross-line standardization | Large-order consistency |

For buyers, strong QC systems mean confidence. Factories that can clearly explain how they control reference samples, materials, process checks, and emotional consistency are far more capable of delivering large teddy bear orders that match approved standards—not just at the beginning, but throughout the entire production run.

How Important Are Safety Certifications and Compliance for Teddy Bear Exports?

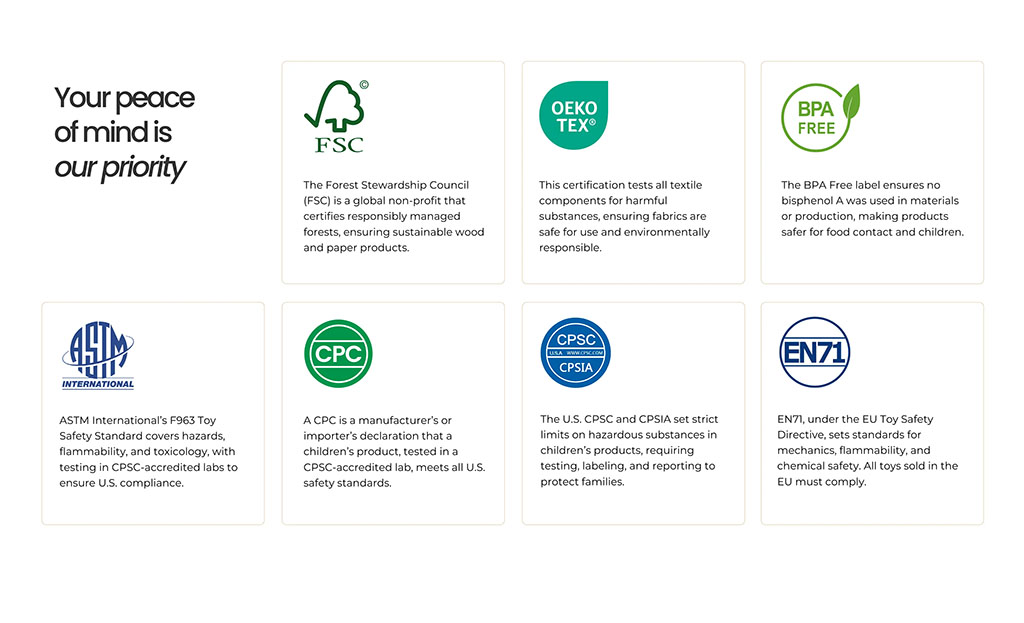

For teddy bears, safety compliance is not just a regulatory requirement—it is a core quality signal. From my experience, buyers who treat certification as a paperwork task often face delays, re-testing, or even shipment rejection. Teddy bears are usually positioned for children, gifting, or emotional comfort, which places them under higher scrutiny than many novelty plush items.

The first layer is market-specific toy safety regulations. For the U.S. market, teddy bears must comply with CPSIA and ASTM F963 requirements, including lead content, phthalates, seam strength, and small parts control. For the EU, EN71 and the Toy Safety Directive apply, with additional REACH chemical restrictions. Professional manufacturers understand that teddy bears—especially those with plastic eyes, noses, or accessories—require careful component-level testing.

Age grading is another critical point. Many teddy bears are intended for young children, sometimes under 3 years old. This affects design choices directly. Factories with strong compliance awareness proactively recommend embroidered eyes, reinforced seams, and secure stuffing structures when age grading is low. Factories that wait for buyers to point this out often lack safety-first thinking.

Material traceability also matters. Teddy bears use large fabric surfaces, which means chemical compliance of fabrics and dyes becomes important. Strong manufacturers can explain how they control fabric sourcing, batch testing, and restricted substance limits—not just provide a generic certificate.

Documentation discipline separates reliable exporters from risky ones. Test reports must match the actual production materials and construction, not just “similar samples.” Factories that manage compliance professionally link test reports to production batches and keep records ready for audits or retailer checks.

| Compliance Area | Weak Factory Approach | Strong Teddy Bear Exporter Approach | Buyer Advantage |

|---|---|---|---|

| Safety standards | Certificate-only focus | Market-specific understanding | Fewer re-tests |

| Age grading | Buyer decides later | Design-for-age guidance | Lower recall risk |

| Component safety | Afterthought | Built-in design choices | Faster approval |

| Material compliance | Generic statements | Traceable fabric control | Regulatory confidence |

| Documentation | One-time testing | Batch-linked records | Retail readiness |

For buyers, safety compliance should be evaluated as part of manufacturing capability, not a separate checkbox. Teddy bear manufacturers who integrate safety thinking into design, material choice, and QC are far more reliable partners—especially for long-term export programs.

What Production Capacity and Lead Time Capabilities Support Retail and Wholesale Needs?

For teddy bear programs, production capacity is not just about “how many pieces a factory can make.” From my experience, what really matters is whether capacity is stable, predictable, and aligned with retail and wholesale timelines. Many sourcing problems happen when buyers assume high capacity equals reliability.

The first factor is effective capacity, not theoretical numbers. A factory may claim large monthly output, but buyers should confirm how much of that capacity is allocated to teddy bear production specifically. Teddy bears often require longer pile fabrics, more careful sewing, and extra finishing steps, which reduces real throughput compared to simple plush items.

Lead time control is equally critical. Retail and wholesale buyers usually work backward from launch dates, promotions, or seasonal peaks. Reliable teddy bear manufacturers build lead times around confirmed material readiness, sampling freeze dates, and production buffers, not optimistic estimates. Factories that quote short lead times without explaining how materials and lines are scheduled often struggle to deliver on time.

Another key point is scalability under repeat orders. Strong factories can ramp up volume for reorders without changing construction quality or delivery rhythm. This requires stable labor teams, standardized work instructions, and backup capacity planning. Factories that rely heavily on temporary labor often show quality fluctuation when volumes increase.

Buyers should also assess how factories handle order mix pressure. During peak seasons, teddy bear orders compete with other plush categories. Reliable manufacturers separate production lines or planning windows for key teddy bear clients, protecting lead time even during busy periods.

| Capacity Indicator | Weak Manufacturer Pattern | Strong Teddy Bear Manufacturer Pattern | Buyer Outcome |

|---|---|---|---|

| Claimed output | Total factory number | Teddy bear–specific capacity | Realistic planning |

| Lead time quoting | Optimistic estimates | Buffer-based schedules | On-time delivery |

| Scaling ability | Quality drops at volume | Stable repeat performance | Reorder confidence |

| Labor stability | Temporary-heavy workforce | Trained, fixed teams | Consistent quality |

| Peak season control | First-come chaos | Planned line allocation | Retail reliability |

For buyers, the right teddy bear manufacturer is one that can commit to timelines with explanation, not promises. Factories that understand retail calendars, protect teddy bear capacity, and manage growth carefully are far better partners for both wholesale programs and long-term retail SKUs.

How Can Communication, Transparency, and Factory Audits Confirm the Right Manufacturer Choice?

At the final selection stage, many teddy bear manufacturers may appear similar on paper. From my experience, communication quality, transparency level, and audit readiness are often what truly separate reliable long-term partners from short-term suppliers.

Communication quality shows up first in how questions are handled. Strong factories answer clearly, confirm understanding, and explain trade-offs. They do not avoid difficult topics such as tolerance limits, risk points, or capacity constraints. Weak factories tend to give short confirmations without substance, which leads to misalignment once production starts.

Transparency is the second signal. Reliable teddy bear manufacturers are open about production processes, material sourcing, QC checkpoints, and even past challenges. Transparency does not mean perfection—it means honesty. Factories that proactively point out risks and propose solutions are usually more trustworthy than those that promise “no problem” to everything.

Factory audits—whether in-person or third-party—are the final validation step. During audits, buyers should look beyond cleanliness and equipment. Pay attention to workflow logic, reference sample control, QC documentation, and staff familiarity with teddy bear standards. A factory that can explain why things are done a certain way usually has internal control.

Audit behavior itself is revealing. Factories confident in their systems welcome audits and prepare structured information. Factories that resist audits, limit access, or rush visits often have gaps they prefer not to expose.

Finally, post-audit follow-up matters. Strong manufacturers respond to audit feedback with corrective plans and timelines. This shows long-term partnership thinking, not just order-driven behavior.

| Evaluation Area | Risk Signal | Strong Manufacturer Signal | Buyer Advantage |

|---|---|---|---|

| Communication | Vague confirmations | Clear explanations & feedback loops | Fewer misunderstandings |

| Transparency | Avoids limitations | Open about risks & solutions | Better planning |

| Audit openness | Restricts access | Welcomes inspection | Trust building |

| Process clarity | “That’s how we do it” | Logical workflow explanation | Operational confidence |

| Follow-up action | No response | Documented improvements | Long-term stability |

For buyers, the right teddy bear manufacturer is not the one that says “yes” the fastest, but the one that communicates clearly, operates transparently, and proves control under audit. These traits protect your brand far beyond the first order.

Conclusion

Selecting the best teddy bear manufacturer in China requires evaluating specialization, design skill, QC discipline, compliance awareness, capacity planning, and transparent communication. When these elements align, buyers gain consistent quality, reliable delivery, and long-term confidence in every teddy bear program.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com