Professional stuffed animal production is not a simple sewing task—it is a structured manufacturing process built to deliver consistency, safety, and scalability. From my experience working with global buyers, the biggest difference between professional factories and basic workshops lies in how each step is defined, controlled, and connected.

Many quality issues seen in mass production can be traced back to early-stage decisions. When processes are unclear or rushed, problems compound as production moves forward. Professional manufacturers focus on building a solid foundation first, ensuring every downstream step runs smoothly.

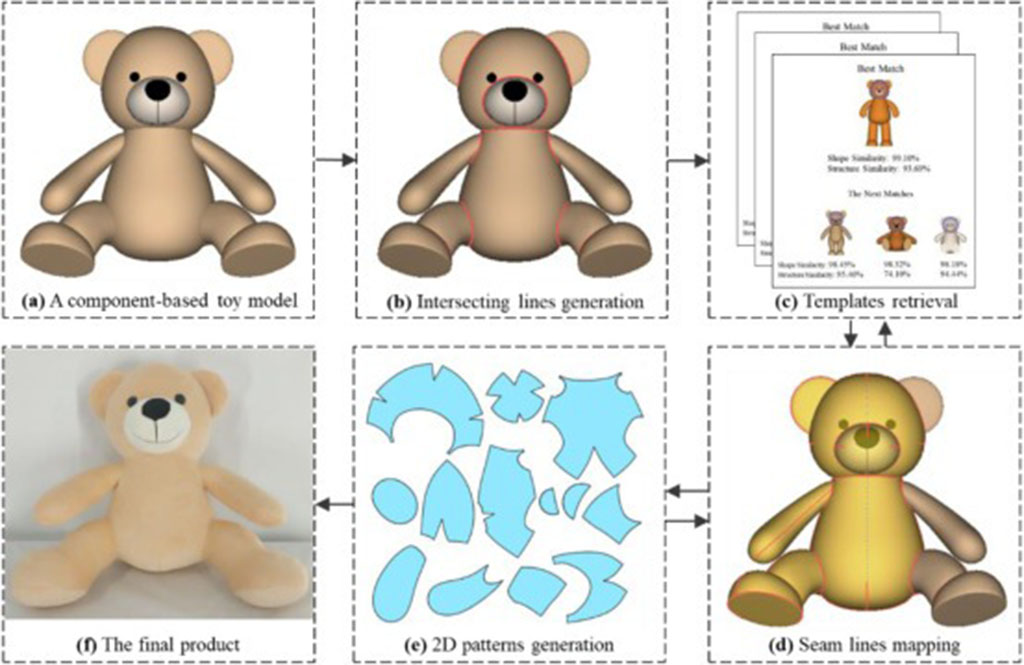

The process begins long before fabric is cut. It starts with design review and pattern development, which determine whether a product can be produced accurately and repeatedly at scale.

How Design Review and Pattern Development Lay the Foundation for Production

Design review and pattern development form the technical backbone of professional stuffed animal production. From my experience, factories that perform this stage well face fewer revisions, lower defect rates, and smoother mass production.

The first step is design feasibility review. Professional manufacturers examine artwork, 3D references, or samples to evaluate proportions, seam logic, material behavior, and safety risks. Instead of blindly following drawings, they identify potential issues early—such as weak seams, unstable shapes, or impractical details—and propose adjustments that preserve design intent.

Pattern development then translates design into structure. Skilled pattern makers convert visual concepts into precise pattern pieces that define shape, balance, and symmetry. This step determines how the plush will look, feel, and hold form after stuffing. Weak pattern work often leads to distortion, uneven tension, or inconsistent sizing during production.

Another critical factor is standardization. Professional factories create master patterns and size specifications that can be reused and controlled across multiple runs or SKUs. This is essential for repeat orders and product collections.

Revision control also matters. When changes are made, professional manufacturers update patterns systematically, track versions, and confirm approvals before moving forward. Informal pattern changes are a common source of production errors.

Finally, good pattern development considers production reality. Patterns are optimized not only for appearance, but also for sewing efficiency, durability, and material yield—supporting stable output at scale.

| Process Element | Non-Professional Approach | Professional Manufacturing Approach | Production Impact |

|---|---|---|---|

| Design review | Executes as-is | Feasibility & risk review | Fewer later issues |

| Pattern making | Visual matching only | Structural & balanced design | Stable shape |

| Standardization | One-off patterns | Master patterns & specs | Repeatability |

| Revision control | Informal changes | Versioned approvals | Error reduction |

| Production fit | Sample-focused | Scale-ready optimization | Smooth mass production |

For buyers, strong design review and pattern development signal that a factory understands how to turn ideas into manufacturable products. When this foundation is solid, every later stage—from cutting to final inspection—becomes more controlled and predictable.

How Fabric Selection, Cutting, and Material Preparation Are Standardized

After patterns are finalized, professional stuffed animal production moves into material execution. From my experience, this stage is where professional factories separate themselves from basic workshops—through standardization, traceability, and preparation discipline.

The first step is fabric and material confirmation. Professional manufacturers do not rely on generic fabric names. They lock material specifications by fiber content, pile length, weight, color standard, and compliance status. Approved materials are recorded in material lists to ensure consistency across production runs and reorders.

Next comes incoming material inspection (IQC). Fabrics, fillings, and accessories are checked for color accuracy, defects, hand feel, and basic safety requirements before entering production. This prevents defective or incorrect materials from reaching the cutting stage, where errors become costly.

Cutting is then executed with precision. Professional factories use cutting templates, dies, or digital cutting systems to ensure size accuracy and symmetry. Fabric direction, nap alignment, and pattern orientation are strictly controlled—especially important for plush fabrics where visual inconsistency is easy to notice.

Material preparation also includes batch control. Fabrics are grouped by lot to avoid color variation within the same order. Accessories and components are pre-sorted and labeled by SKU or production line, reducing mix-ups during sewing.

Finally, professional manufacturers prepare materials based on production flow, not convenience. Kits are prepared line by line, supporting balanced output and reducing downtime once sewing begins.

| Material Stage | Basic Supplier Practice | Professional Manufacturing Practice | Quality Impact |

|---|---|---|---|

| Material definition | Generic fabric names | Locked specifications | Consistent appearance |

| Incoming inspection | Minimal or skipped | Formal IQC checks | Early defect control |

| Cutting accuracy | Manual estimation | Template/digital cutting | Size consistency |

| Fabric orientation | Random | Nap & direction control | Visual uniformity |

| Material preparation | Bulk piles | Line-based kitting | Efficient assembly |

For buyers, standardized fabric selection and preparation ensure that what was approved is what gets produced. When materials are controlled before sewing starts, downstream quality becomes far more predictable and scalable.

How Sewing, Assembly, and Shaping Define Structural Quality

Sewing and assembly are where a stuffed animal’s structural quality is truly formed. From my experience, even with good materials and patterns, poor sewing discipline quickly leads to distortion, weak seams, and inconsistent appearance—especially at scale.

Professional manufacturers begin with standardized sewing specifications. Stitch type, stitch density, seam allowance, and reinforcement points are clearly defined and shared with operators. This ensures that seams hold shape after stuffing and withstand handling, washing, and long-term use.

Assembly sequence matters. Experienced factories follow a fixed order for joining body parts—head, limbs, torso, and accessories—so tension is distributed evenly. Random or improvised assembly often causes asymmetry or stress points that only appear after stuffing.

Shaping control is another differentiator. During sewing, operators adjust alignment and curvature to preserve intended proportions. This is especially important for facial areas and joints. Professional teams are trained to recognize early distortion and correct it before defects multiply.

Equipment and skill balance also play a role. Professional factories match machines and operators to fabric types and complexity levels. Difficult areas are handled by experienced staff, not rushed through to meet output targets.

Finally, in-line checks during sewing prevent defects from moving forward. Supervisors or IPQC staff inspect seam strength, alignment, and consistency before pieces proceed to stuffing.

| Assembly Factor | Basic Workshop Practice | Professional Manufacturing Practice | Structural Result |

|---|---|---|---|

| Sewing standards | Operator-dependent | Defined stitch & seam specs | Strong seams |

| Assembly order | Flexible | Fixed, proven sequence | Balanced structure |

| Shaping control | Afterthought | In-process alignment checks | Correct proportions |

| Skill allocation | Random assignment | Matched skills & tasks | Fewer defects |

| In-line checks | Rare | Regular IPQC checks | Early correction |

For buyers, controlled sewing and assembly ensure that stuffed animals maintain shape, strength, and consistency across large runs. This stage transforms prepared materials into reliable products ready for stuffing and finishing.

How Stuffing, Closing, and Form Control Ensure Consistent Appearance

Stuffing and closing are decisive steps for a stuffed animal’s final appearance and hand feel. From my experience, many products that look correct before stuffing lose their intended shape at this stage if form control is weak or inconsistent.

Professional manufacturers treat stuffing as a controlled process, not a manual afterthought. Filling weight ranges are defined by product size and style, with clear tolerances. This ensures that every unit feels consistent in firmness and weight, regardless of who performs the operation.

Equally important is distribution control. Filling must be evenly placed across the head, body, and limbs to avoid lumps, flat spots, or imbalance. Skilled operators shape the plush during stuffing, not after, preserving proportions set during pattern making and sewing.

Closing methods also affect appearance and durability. Professional factories specify closing techniques—hand stitching or machine closing—based on product requirements. Stitch density, tension, and thread matching are controlled to ensure closures are secure and visually clean.

Form control continues after closing. Products are gently reshaped, aligned, and visually checked to confirm symmetry and posture. For styles that require standing or sitting positions, form correction is done before the product leaves the station.

Finally, in-line inspection plays a role. Supervisors check stuffing consistency and closure quality before products move to the next stage, preventing appearance issues from accumulating.

| Form Control Stage | Basic Supplier Practice | Professional Manufacturing Practice | Visual Outcome |

|---|---|---|---|

| Filling quantity | Estimated by feel | Defined weight ranges | Consistent firmness |

| Filling distribution | Uneven | Balanced shaping during fill | Smooth surface |

| Closing method | Random choice | Specified technique | Clean finish |

| Form correction | Minimal | Post-close reshaping | Correct posture |

| In-line inspection | Occasional | Routine checks | Appearance stability |

For buyers, controlled stuffing and form management ensure that finished products look uniform, well-shaped, and shelf-ready. This consistency is critical for brand presentation, especially across large production runs.

How In-Line Quality Control and Safety Checks Are Applied During Production

In professional stuffed animal production, quality and safety are controlled during manufacturing—not inspected in at the end. From my experience, in-line quality control is what prevents small deviations from becoming large-scale defects.

The first layer is process-based in-line inspection (IPQC). Trained inspectors or line leaders check critical points as production moves forward—cutting accuracy, embroidery placement, seam strength, stuffing balance, and closure quality. These checks are timed and standardized, not random.

Safety checks are integrated into the same flow. For products with accessories or decorative elements, pull-force checks and attachment inspections are conducted during assembly, not after packing. This ensures that unsafe components are corrected before they move downstream.

Another key element is defect isolation. When issues are found, affected pieces are separated immediately. Professional factories stop the line if needed, identify root causes, and correct processes before resuming. Basic suppliers often continue production and rely on final inspection to catch problems later.

Documentation supports consistency. Inspection results, defect types, and corrective actions are recorded by station or line. This data allows supervisors to see patterns and adjust training or processes in real time.

Finally, in-line QC scales with volume. As output increases, inspection frequency and scope increase accordingly. Using the same QC intensity for small and large runs is a common failure point among non-professional operations.

| In-Line Control Area | Basic Supplier Practice | Professional Manufacturing Practice | Risk Reduction |

|---|---|---|---|

| Inspection timing | End-of-line only | Process-stage IPQC | Early correction |

| Safety checks | Final inspection | In-process verification | Fewer recalls |

| Defect handling | Rework later | Immediate isolation & fix | Contained issues |

| Record keeping | Minimal | Logged & reviewed data | Continuous control |

| Scale adaptation | Fixed checks | QC scales with volume | Stable output |

For buyers, strong in-line quality and safety control ensure that products remain consistent, compliant, and predictable throughout production—long before final inspection begins.

How Final Inspection, Packaging, and Pre-Shipment Preparation Complete the Process

Final inspection and pre-shipment preparation are not about finding faults—they are about confirming readiness for the market. From my experience, professional stuffed animal manufacturers use this stage to validate that everything agreed earlier has been executed correctly and consistently.

Final inspection (FQC) is conducted against approved standards, not subjective judgment. Inspectors check appearance, measurements, stitching quality, stuffing consistency, accessories security, labeling, and overall workmanship based on AQL or buyer-defined criteria. This ensures decisions are data-driven and defensible.

Packaging control is equally important. Professional factories follow packaging specifications covering polybag thickness, warning labels, carton strength, packing ratios, and carton markings. Correct packaging protects products during transit and ensures compliance with retailer and logistics requirements.

Pre-shipment preparation also includes quantity verification and carton checks. Carton counts, weights, and dimensions are confirmed to match shipping documents. This reduces customs issues, warehouse discrepancies, and unexpected logistics costs.

Another key step is shipment documentation readiness. Packing lists, invoices, test reports, and compliance documents are reviewed for accuracy and completeness before goods leave the factory. Missing or incorrect documents are a common cause of shipment delays.

Finally, professional manufacturers conduct pre-shipment risk review. Any deviations, reworks, or special conditions are communicated clearly to buyers before dispatch—ensuring transparency and informed release decisions.

| Final Stage Area | Basic Supplier Practice | Professional Manufacturing Practice | Shipment Outcome |

|---|---|---|---|

| Final inspection | Visual check only | Standard-based FQC | Verified quality |

| Packaging control | Generic packing | Spec-defined packaging | Transit safety |

| Quantity checks | Estimated counts | Verified carton & units | Fewer disputes |

| Documentation | Prepared last-minute | Reviewed & complete | Smooth customs |

| Pre-shipment review | Silent shipment | Buyer-informed release | Predictable delivery |

For buyers, a controlled final inspection and shipment process ensures that products arrive as expected, compliant, and ready for sale. This final stage completes the professional manufacturing cycle and protects all the work done upstream.

Conclusion

Professional stuffed animal production relies on structured processes, not individual skill. When every stage—from design review to shipment—is standardized and controlled, brands gain consistent quality, safety compliance, and predictable delivery at scale.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com