You approve the sample. It looks perfect. The shape is right, the fabric feels correct, the embroidery is aligned. But when bulk production arrives, something feels slightly different. The head is softer. The color tone looks off. The stitching feels tighter.

This is what we call a sample-to-production gap.

In plush toy manufacturing, this gap is one of the most common risks brands face. The good news is that it is preventable. With the right systems, documentation, and alignment processes, mass production can match the approved sample consistently.

Let’s first understand why these gaps happen.

What Causes Differences Between Approved Samples and Mass Production?

Sample-to-production gaps rarely happen because of one big mistake. They usually occur due to small deviations that accumulate during scaling.

From my experience, the most common causes include the following.

First, material substitution during bulk purchasing.

During sampling, fabric may come from a limited roll. During mass production, a new batch is purchased. Even slight differences in pile density, backing thickness, or dye shade can change appearance and feel.

Second, stuffing weight inconsistency.

If stuffing weight tolerance is not clearly defined, operators may rely on hand feel instead of measurement. This creates firmness variation across units.

Third, sewing tension differences.

Different production lines or operators may adjust machine tension slightly. This affects seam tightness and overall shape balance.

Fourth, embroidery file or placement drift.

If embroidery positioning is not locked using placement guides, slight shifts may occur between batches.

Fifth, lack of detailed technical documentation.

If the approved sample exists without a full specification sheet, production teams may interpret details differently.

Sixth, no clear golden reference control.

If the approved sample is not used as the main benchmark during production, visual alignment can gradually drift.

Here is a simplified breakdown:

| Gap Cause | How It Happens | Visible Result |

|---|---|---|

| Fabric batch change | New dye lot | Slight color variation |

| Stuffing variance | No weight control | Soft/firm differences |

| Sewing tension shift | Operator variation | Shape distortion |

| Embroidery drift | Placement not locked | Misaligned face/logo |

| Missing specs | Unclear instructions | Inconsistent execution |

| No golden control | No visual reference | Production drift |

For brands, these issues are frustrating because they feel unpredictable. But in reality, they are process-related, not random.

At Kinwin, preventing sample-to-production gaps starts with identifying these risk points before bulk production begins. When the causes are controlled, consistency becomes much easier to achieve.

How Do Detailed Tech Packs and Material Specs Reduce Production Deviations?

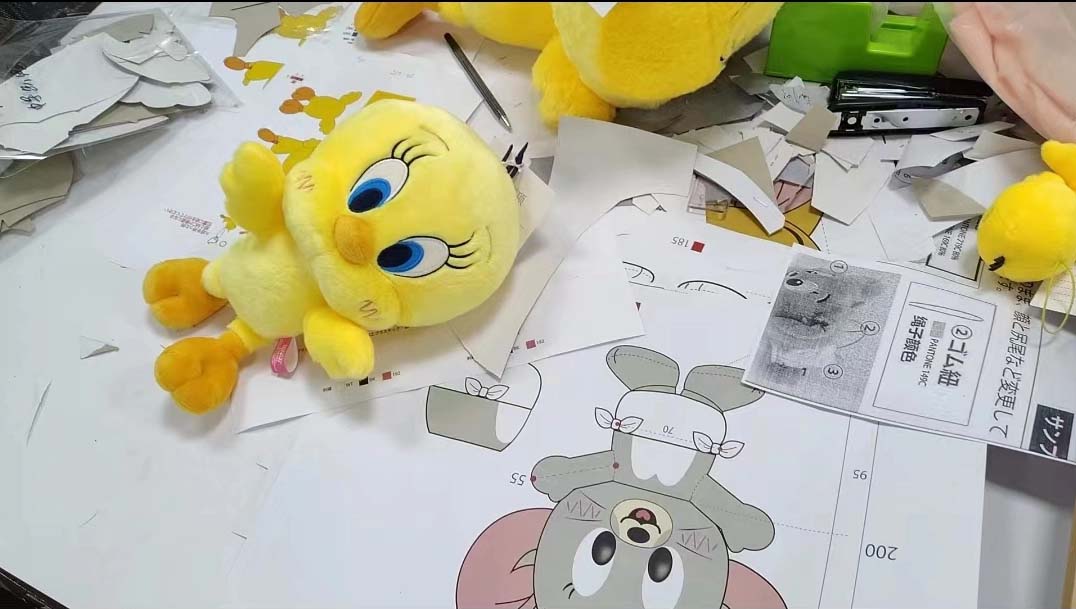

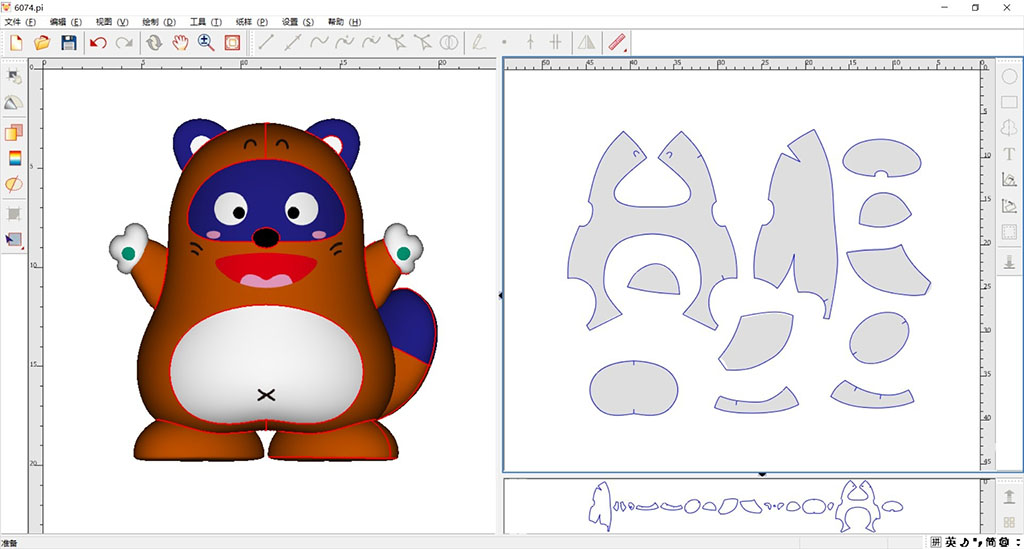

If the approved sample is the visual reference, the tech pack is the technical language behind it. Without a detailed tech pack, production teams rely on memory or assumptions. That is where deviations begin.

A professional plush tech pack does more than show measurements. It defines how the product must be made, step by step.

Here is what a strong tech pack should include:

First, full measurement chart with tolerances.

Every key dimension—overall height, head width, arm length, stuffing weight—should have allowable variation ranges. This turns quality from subjective judgment into measurable standards.

Second, fabric and material codes.

Fabric type, color reference (Pantone if needed), pile direction, thread type, filling grade, and accessory codes must be locked. This prevents material substitution confusion during bulk sourcing.

Third, stitching standards.

Define stitch density per centimeter, reinforcement areas, and seam types. This ensures structural consistency across production lines.

Fourth, embroidery and printing files.

Include approved embroidery digitizing files, thread color codes, logo placement diagrams, and print artwork references.

Fifth, assembly instructions.

Clear guidance on stuffing sequence, shaping method, and final inspection points reduces variation between operators.

Here’s how tech pack detail level impacts production stability:

| Documentation Level | Risk Level | Production Result |

|---|---|---|

| Basic sample only | High | Interpretation-based |

| Partial specs | Medium | Controlled but flexible |

| Full tech pack | Low | Standardized execution |

Material specification sheets also play a key role. When fabric batches are purchased for bulk production, they should be checked against:

- Approved color swatches

- Pile direction standards

- Thickness tolerance

- Backing density

If these checks are skipped, small material changes can lead to visible differences in final product feel and appearance.

At Kinwin, once a sample is approved, we convert it into a detailed production specification document before bulk begins. This document is shared across cutting, sewing, stuffing, and QC teams. Everyone works from the same reference—not memory.

For buyers, asking “Do you create a full tech pack before mass production?” is one of the simplest ways to evaluate whether a factory can truly maintain consistency.

Clear documentation reduces interpretation. Reduced interpretation reduces deviation.

How Does a Golden Sample Control Bulk Manufacturing Consistency?

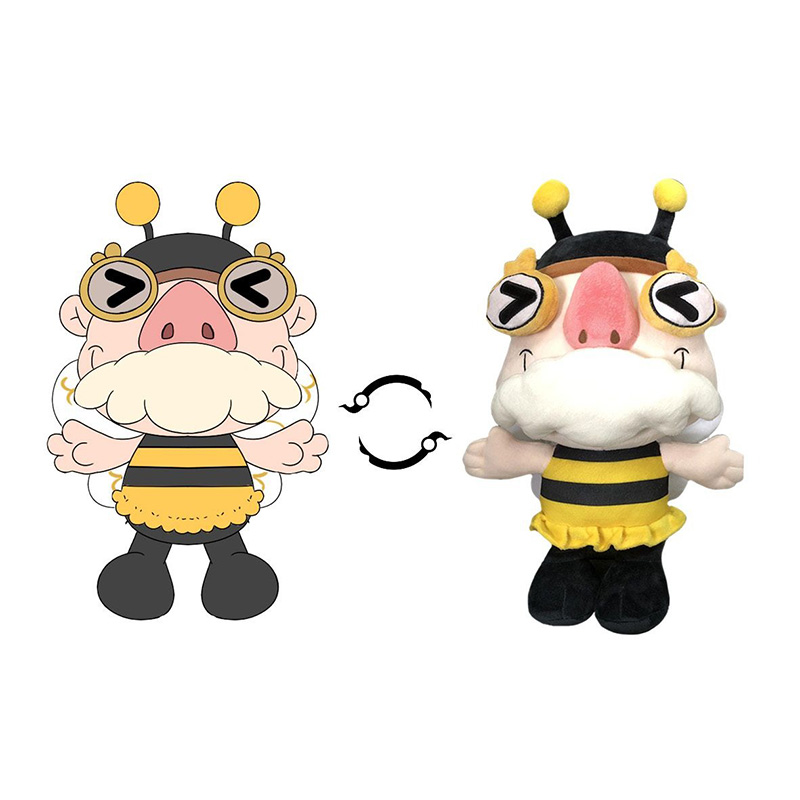

A golden sample is more than an approved prototype. It is the physical contract between the brand and the factory. Once signed off, it becomes the visual and structural benchmark for every unit produced.

Without a properly managed golden sample, production teams may slowly drift away from the original standard—even if they don’t intend to.

Here’s why golden sample control is so important.

First, it aligns all departments to one reference.

Cutting, sewing, stuffing, embroidery, QC, and packaging teams should all refer to the same approved unit. If different departments rely on photos or memory, inconsistencies appear.

Second, it locks visual expectations.

The golden sample defines not just measurements, but also softness level, surface appearance, embroidery clarity, and overall balance.

Third, it reduces interpretation risk during operator changes.

In long production cycles, operators may rotate. A golden sample ensures that new team members understand the exact quality level required.

Fourth, it supports inspection alignment.

QC inspectors compare production units directly against the golden sample rather than subjective judgment.

Fifth, it prevents “small drift” across batches.

When producing thousands of pieces, tiny adjustments—slightly tighter stuffing or minor thread changes—can accumulate. Golden sample comparison catches these early.

Here’s how golden sample control protects consistency:

| Golden Sample Function | What It Controls | Risk Prevented |

|---|---|---|

| Visual benchmark | Color & shape | Appearance drift |

| Structural reference | Firmness & balance | Shape deviation |

| QC comparison tool | Inspection standard | Subjective judgment |

| Operator alignment | Process consistency | Skill variation |

| Batch comparison | Multi-lot stability | Long-term drift |

However, golden sample control only works if it is actively used.

Professional factories typically:

- Store golden samples in protected conditions

- Tag and document approval date

- Use it during pre-production meeting (PPM)

- Compare it during in-line inspection

- Refer to it during final inspection

At Kinwin, we keep golden samples in controlled storage and require QC teams to reference them during production. This ensures that what you approved is what you receive—not something close, but something aligned.

For brands, always confirm:

- Is the golden sample stored and documented?

- Will production and QC use it actively?

When golden sample control is taken seriously, sample-to-production gaps reduce significantly.

What Role Does Pre-Production Meeting (PPM) Play in Alignment?

Many sample-to-production gaps happen because production starts too quickly. Even when a golden sample and tech pack exist, teams may interpret instructions differently if there is no final alignment before bulk begins.

This is where a Pre-Production Meeting (PPM) becomes critical.

A PPM is a structured meeting held before mass production starts. Its purpose is to align all departments on standards, materials, tolerances, and risk points.

A professional PPM typically covers the following:

First, golden sample review.

The approved sample is physically reviewed by supervisors, line leaders, and QC teams to confirm expectations.

Second, tech pack confirmation.

Key measurements, stitching density, stuffing weight, embroidery placement, and tolerance ranges are reviewed.

Third, material verification.

Bulk fabric batches, thread types, and filling materials are confirmed against approved references.

Fourth, critical risk discussion.

Stress points (such as arm joints or decorative parts) are identified for extra monitoring.

Fifth, quality checkpoint planning.

In-line QC stages and inspection frequency are clarified.

Sixth, packaging and labeling instructions.

Retail packaging, barcode labels, care instructions, and carton packing methods are reconfirmed.

Here’s how PPM reduces risk:

| PPM Focus Area | Why It Matters | Risk Prevented |

|---|---|---|

| Golden sample review | Visual alignment | Shape deviation |

| Spec confirmation | Measurable control | Tolerance confusion |

| Material check | Batch stability | Color variation |

| Risk discussion | Proactive control | Structural failure |

| QC planning | Clear checkpoints | Late detection |

| Packaging alignment | Market readiness | Labeling errors |

Without a PPM, departments may work independently. With a PPM, everyone starts from the same page.

At Kinwin, we conduct internal PPM before launching large plush orders. Key supervisors, QC managers, and production leaders review documentation and physical samples together. This alignment step significantly reduces early-stage production drift.

For buyers, asking whether a factory conducts a structured pre-production meeting is a strong indicator of operational discipline.

Alignment before production reduces correction after production.

How Do In-Line Inspections Prevent Early-Stage Production Drift?

Even with a strong tech pack, golden sample, and PPM alignment, production still involves human work and machine operations. Small deviations can happen at any time. The key is detecting them early—before they spread across the entire batch.

In-line inspection (IPQC) is designed exactly for this purpose.

Instead of waiting until the end of production, in-line QC monitors quality at each critical stage. It acts as a real-time correction system.

Here’s how in-line inspections prevent early-stage drift:

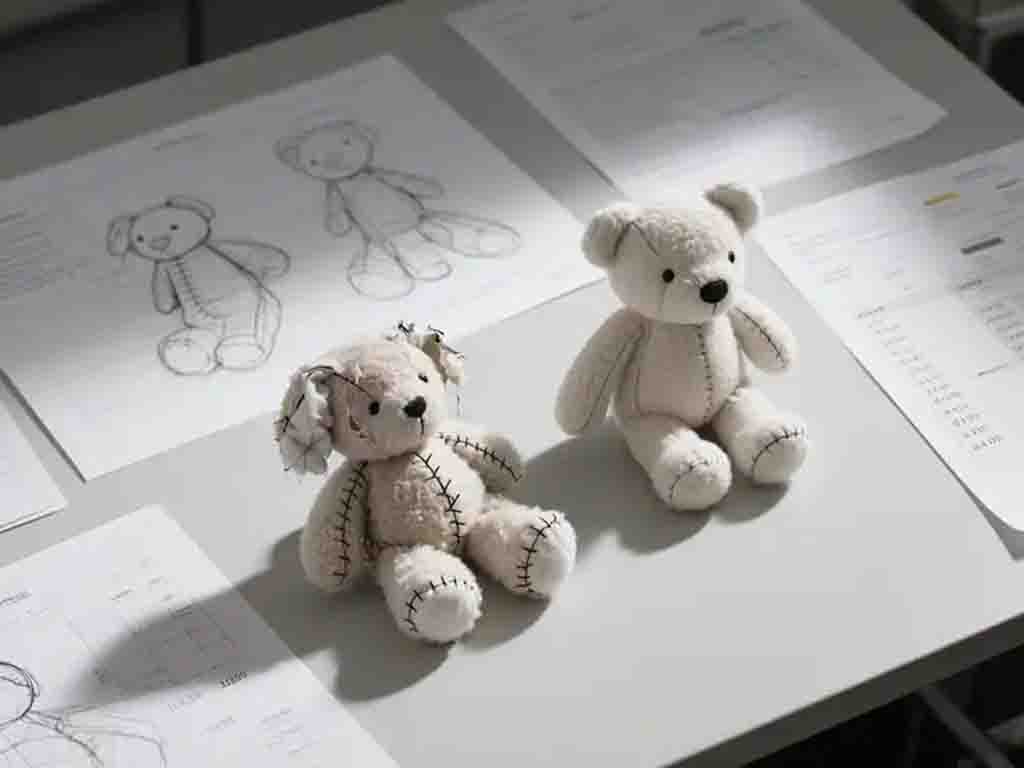

First, first-piece approval on the production line.

Before full-speed production begins, the first completed unit is reviewed against the golden sample. Any deviation is corrected immediately.

Second, regular sampling during sewing.

QC checks stitch density, seam alignment, reinforcement strength, and symmetry during sewing operations—not after hundreds of units are finished.

Third, stuffing weight verification.

Random units are weighed to ensure filling tolerance matches approved standards. This prevents firmness inconsistency.

Fourth, embroidery placement checks.

Positioning templates are verified repeatedly to avoid gradual shifting of eyes or logos.

Fifth, shape balance review.

Inspectors check posture, sitting stability, and proportion consistency during assembly.

Sixth, immediate correction feedback.

If a deviation is detected, production pauses for adjustment instead of continuing.

Here’s how in-line control works as a protection system:

| In-Line Control Stage | What Is Checked | Production Risk Prevented |

|---|---|---|

| First-piece check | Overall shape & finish | Early misalignment |

| Sewing stage | Seam strength & tension | Structural weakness |

| Stuffing stage | Weight & distribution | Shape variation |

| Decoration stage | Alignment & clarity | Brand inconsistency |

| Assembly stage | Proportion balance | Batch drift |

| Ongoing sampling | Random variation | Accumulated deviation |

Without in-line inspection, small issues grow unnoticed. With in-line monitoring, deviations are corrected when they are still manageable.

At Kinwin, QC personnel are positioned directly on production lines. They compare ongoing units to the golden sample and technical documents in real time. This reduces correction cost and protects delivery timelines.

For buyers, asking “How frequently do you conduct in-line inspections during production?” helps evaluate how actively a factory controls quality.

Early detection equals lower risk.

How Can Clear Communication and Documentation Minimize Rework Risks?

Even with strong QC systems, many production gaps happen because of unclear communication. In plush manufacturing, details matter. If instructions are vague or changes are not documented properly, small misunderstandings can turn into expensive rework.

Clear communication is not about sending more messages. It is about sending structured, documented, and confirmed information.

Here is how communication reduces production risk:

First, written confirmation of every change.

If embroidery size is adjusted or stuffing weight is modified, it must be updated in the tech pack and confirmed in writing. Verbal changes easily cause confusion.

Second, version control for documents.

Using updated file versions prevents teams from referencing outdated measurements or old artwork files.

Third, centralized project management.

Having one dedicated project manager reduces cross-department miscommunication and keeps feedback organized.

Fourth, photo and video confirmations during production.

Sharing mid-production updates allows buyers to catch concerns early rather than after shipment.

Fifth, structured revision tracking.

Every revision round should record what changed, why it changed, and how it was approved.

Sixth, post-production review reports.

After order completion, reviewing defect rate and improvement points strengthens future production stability.

Here’s how documentation discipline prevents rework:

| Communication Practice | What It Prevents | Long-Term Benefit |

|---|---|---|

| Written approvals | Misinterpretation | Clear accountability |

| Version control | Using outdated files | Stable execution |

| Dedicated PM | Mixed instructions | Efficient coordination |

| Mid-production updates | Late-stage surprises | Faster correction |

| Revision logs | Repeated mistakes | Continuous improvement |

| Post-order review | Recurring issues | Stronger partnership |

Rework increases cost, delays shipment, and damages trust. Clear documentation reduces that risk dramatically.

At Kinwin, we assign a dedicated project coordinator for each order. All technical changes are recorded, approved, and aligned across teams before execution. This structured communication model protects both quality and delivery timeline.

For brands, asking how a factory manages documentation and change tracking is just as important as asking about QC.

Conclusion

Sample-to-production gaps are not random accidents. They are process issues that can be prevented through detailed tech packs, golden sample control, structured PPM alignment, in-line inspections, and disciplined communication.

When systems are strong, mass production can truly reflect the approved sample.

If you are preparing a custom plush order and want a manufacturing partner focused on consistency and risk control, our team at Kinwin is ready to support your project.

Contact: [email protected]

Visit: https://kinwintoys.com