Plush toys may look simple on the outside, but behind every soft product is a complex manufacturing process. When quality issues appear, they rarely come from one single mistake. Most problems are caused by weak material control, inconsistent processes, or lack of supervision during production.

For brands, retailers, and wholesalers, understanding common quality issues helps you ask the right questions before placing large orders. The earlier these risks are identified, the easier they are to control. Let’s begin with one of the most overlooked areas—fabric defects.

What Fabric Defects Commonly Appear in Plush Toy Production?

Fabric is the foundation of every plush toy. If fabric quality is unstable, no amount of good sewing can fully correct the problem. In bulk production, fabric defects are one of the most common sources of customer complaints.

From my experience, fabric issues usually fall into five main categories.

First, inconsistent pile direction. Plush fabrics have fibers that reflect light differently depending on direction. If panels are cut without controlling pile alignment, different parts of the toy may appear darker or lighter even when using the same fabric batch.

Second, uneven pile density. Some fabric rolls may have thinner fiber areas. When used in visible areas such as the face or belly, the toy may look patchy or worn even though it is new.

Third, color inconsistency between batches. Even small dye variations can cause noticeable shade differences between production lots. This is especially critical for brand-specific colors.

Fourth, fabric stretching and deformation. Lower-quality backing fabric may stretch during sewing and stuffing. This leads to distorted shapes and poor symmetry.

Fifth, surface defects. Oil marks, fiber shedding, loose threads, or weaving flaws can appear if incoming materials are not properly inspected.

Here is how fabric defects impact final products:

| Fabric Issue | Visible Effect | Risk for Brand |

|---|---|---|

| Pile direction mismatch | Uneven color tone | Perceived low quality |

| Uneven pile density | Patchy surface | Customer dissatisfaction |

| Dye variation | Color mismatch | Brand inconsistency |

| Stretching | Shape distortion | Structural weakness |

| Surface defects | Visible flaws | Returns & complaints |

For buyers, fabric control should start before cutting begins. Reliable factories conduct incoming fabric inspection, color comparison tests, and sample cutting verification. At Kinwin, we lock fabric batches and verify pile direction during cutting to avoid visual inconsistencies in bulk orders.

If fabric quality is stable, many later problems can be avoided. If not, defects multiply quickly across thousands of pieces.

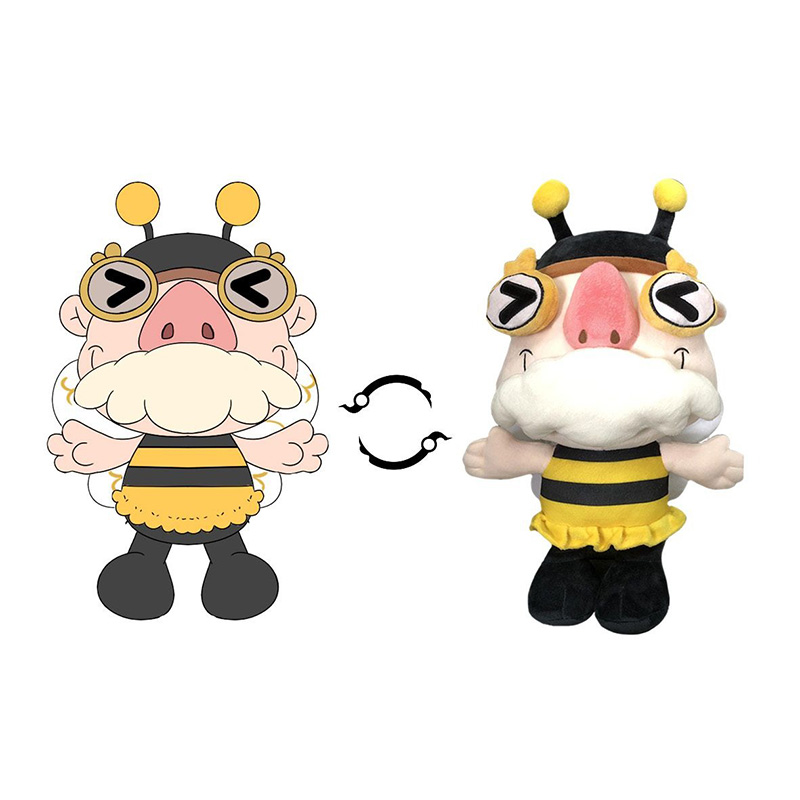

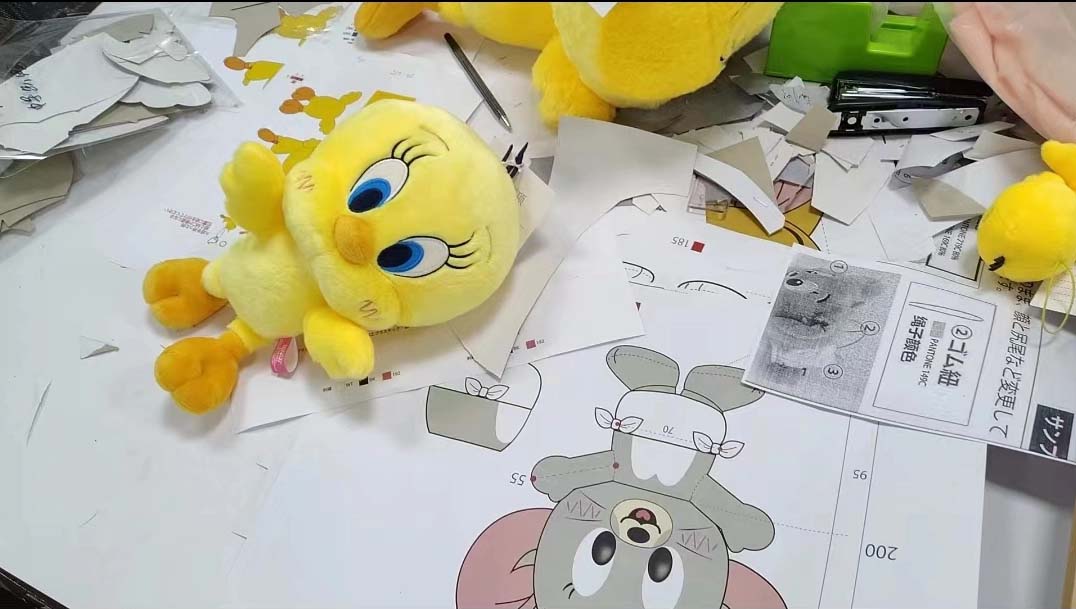

How Do Cutting and Pattern Errors Affect Final Product Shape?

Even when fabric quality is good, mistakes during cutting and pattern execution can quickly damage the final appearance of a plush toy. In mass production, small measurement deviations become large visual differences when repeated across hundreds or thousands of units.

From a manufacturing perspective, cutting and pattern errors are among the most structural quality risks.

Common cutting and pattern-related issues include:

First, inaccurate pattern scaling. If patterns are resized improperly without adjusting seam allowances or volume ratios, proportions may shift. The head may look slightly larger, or the body slightly shorter, compared to the approved sample.

Second, inconsistent seam allowance. When cutting lines are not aligned with pattern markers, seam allowance may vary. This affects how panels join together, changing curvature and fullness.

Third, asymmetrical panel cutting. Left and right parts must be mirrored accurately. Even minor differences can cause uneven arms, legs, or facial imbalance.

Fourth, failure to control fabric stretch direction. Plush fabrics stretch more in one direction than another. If panels are cut inconsistently relative to stretch direction, shapes may distort after stuffing.

Fifth, manual cutting inconsistency in large volumes. Without clear cutting templates or CNC assistance, manual errors accumulate during bulk production.

Here is how cutting issues translate into visible problems:

| Cutting / Pattern Error | Visible Result | Long-Term Risk |

|---|---|---|

| Pattern scaling error | Proportion mismatch | Brand inconsistency |

| Uneven seam allowance | Irregular curves | Shape instability |

| Asymmetrical panels | Crooked appearance | Customer complaints |

| Stretch direction ignored | Distorted body | Poor durability |

| Manual cutting variance | Batch inconsistency | Return risk |

For buyers, this is why reviewing only the final sample is not enough. You should also understand how the factory controls pattern storage, cutting standards, and size tolerances.

At Kinwin, once a sample is approved, patterns are digitally stored and standardized. Cutting processes are aligned with fabric stretch direction and seam allowances are checked before mass production begins. These controls prevent small pattern errors from becoming large bulk problems.

Cutting accuracy protects shape consistency. When shape stays stable, brand image stays stable too.

Why Do Stitching and Seam Problems Lead to Structural Weakness?

If cutting defines shape, stitching defines strength. Many serious plush toy defects do not come from fabric itself, but from how pieces are sewn together. Weak seams may not be obvious at first glance, but they often appear after handling, washing, or light pulling.

From a buyer’s perspective, stitching quality directly affects durability, safety, and customer satisfaction.

Common stitching and seam issues include:

First, loose stitch density. If stitch count per inch is too low, seams may separate under pressure. This often appears at stress points like underarms, neck joints, and leg attachments.

Second, uneven stitching tension. When thread tension is inconsistent, seams may pucker or wrinkle. This distorts the plush surface and changes intended proportions.

Third, skipped stitches. Machine malfunction or operator inattention can create gaps in seams. These weak points increase the risk of tearing during use.

Fourth, improper thread selection. Threads that are too thin or low strength cannot handle stuffing pressure. This leads to seam cracking over time.

Fifth, poor reinforcement at key joints. Arms, legs, ears, and tails require reinforcement stitching. Without it, parts may loosen or detach, especially in children’s products.

Here is how stitching defects affect product performance:

| Stitching Issue | Immediate Effect | Long-Term Risk |

|---|---|---|

| Low stitch density | Loose seams | Seam opening |

| Uneven tension | Surface wrinkles | Shape distortion |

| Skipped stitches | Weak connection | Tearing under stress |

| Weak thread | Breakage | Reduced durability |

| No joint reinforcement | Loose parts | Safety concerns |

For brands targeting international markets, seam strength is not just about durability. It is also about compliance. Pull tests and seam strength tests are required in many regions. Poor stitching can lead to failed safety testing.

That is why professional factories use:

- Standard stitch density guidelines

- Reinforced stitching at stress points

- Regular machine maintenance

- In-line seam strength checks

- Random pull tests during production

At Kinwin, seam strength is treated as a safety control, not just a cosmetic detail. We monitor stitch density and reinforce high-stress areas to prevent structural weakness in bulk production.

When stitching is stable, the plush toy holds its shape, passes compliance tests, and performs reliably in the hands of customers.

What Stuffing Inconsistencies Cause Shape Deformation and Imbalance?

Stuffing may look simple, but it plays a critical role in plush toy structure. Even if fabric, cutting, and stitching are correct, inconsistent stuffing can completely change the final appearance and feel of the product.

In bulk production, stuffing control is one of the most common hidden quality risks.

Common stuffing-related issues include:

First, inconsistent stuffing weight. If operators rely only on hand feel instead of measured weight standards, some units may feel softer while others feel too firm. This leads to noticeable differences within the same batch.

Second, uneven distribution. Stuffing that is not properly shaped inside the head or body can cause asymmetry. One side may look fuller, or the plush may lean when sitting.

Third, overstuffing. Too much filling creates seam stress and distorts proportions. It may also cause visible bulging at stitch lines.

Fourth, understuffing. Insufficient filling makes the toy collapse or wrinkle, especially around the face and belly.

Fifth, inconsistent filling material quality. Lower-grade polyester fiber may clump or flatten quickly after use, reducing long-term shape stability.

Here is how stuffing inconsistencies affect product quality:

| Stuffing Issue | Visible Result | Long-Term Risk |

|---|---|---|

| Weight variation | Uneven firmness | Customer complaints |

| Poor distribution | Asymmetry | Brand inconsistency |

| Overstuffing | Distorted shape | Seam failure |

| Understuffing | Collapsed appearance | Low perceived value |

| Low-grade fiber | Loss of shape | Negative reviews |

For buyers, stuffing consistency matters because customers immediately feel it when holding the toy. Softness, balance, and shape are emotional factors in purchasing decisions.

Professional factories control stuffing through:

- Defined stuffing weight standards for each size

- Digital scales for consistent filling

- Manual shaping procedures before final closure

- Random batch checks for weight tolerance

- High-resilience fiber selection

At Kinwin, stuffing weight is recorded and controlled according to sample standards. This ensures that bulk production matches the approved feel and balance of the original sample.

When stuffing is controlled correctly, plush toys maintain shape, pass compression tests, and deliver consistent user experience across large orders.

How Do Embroidery and Printing Errors Impact Brand Presentation?

In plush toys, embroidery and printing are often where brand identity appears. Eyes, logos, facial expressions, text, and decorative elements all rely on precision. When embroidery or printing quality is unstable, the entire product can look unprofessional—even if structure and materials are correct.

From a brand perspective, decoration errors are highly visible and often the first thing customers notice.

Common embroidery-related issues include:

First, misaligned embroidery placement. If positioning is not standardized, eyes or logos may shift slightly from left to right across batches, affecting symmetry and character expression.

Second, uneven stitch density. Loose or overly tight embroidery changes the texture and clarity of details.

Third, color mismatch in thread selection. Even small differences in thread shade can alter brand colors.

Fourth, embroidery pulling fabric. If stabilizers are not used properly, embroidery can cause surface distortion, especially on soft or stretchy plush fabrics.

Common printing-related issues include:

- Blurred or unclear printed graphics

- Color fading after washing

- Ink bleeding into surrounding fabric

- Inconsistent print positioning

Here is how embroidery and printing defects impact product quality:

| Decoration Issue | Visible Effect | Brand Risk |

|---|---|---|

| Misalignment | Crooked eyes/logo | Character distortion |

| Loose stitch density | Unclear details | Cheap appearance |

| Color mismatch | Off-brand tone | Brand inconsistency |

| Fabric pulling | Surface wrinkling | Reduced quality feel |

| Blurry printing | Poor clarity | Customer dissatisfaction |

For retail brands, decorative accuracy directly affects shelf appeal and online product photos. Small visual errors can lead to customer returns or negative reviews.

Professional factories reduce decoration risks by:

- Using digital embroidery positioning templates

- Locking approved thread color codes

- Conducting first-piece embroidery confirmation

- Testing print adhesion and wash resistance

- Performing in-line inspection during decoration process

At Kinwin, embroidery files and placement guides are standardized after sample approval. First-piece confirmation is required before full batch decoration begins. This prevents brand-related errors from spreading across large orders.

When decoration quality is controlled, brand identity remains consistent—and customer trust remains strong.

How Can In-Line Quality Control Prevent Bulk Production Defects?

Most serious plush toy quality problems do not appear at the end—they start in the middle of production. If defects are only discovered during final inspection, it is often too late. Rework costs increase, delivery timelines are delayed, and batch consistency is already compromised.

This is why in-line quality control (IPQC) is critical.

In-line quality control means monitoring production at each stage instead of waiting until the product is finished.

Key in-line control points include:

- Fabric inspection before cutting Check color consistency, pile direction, surface defects, and batch alignment.

- First-piece confirmation after cutting Ensure pattern accuracy and seam allowance consistency before mass sewing begins.

- Seam strength and stitch density checks Inspect random pieces during sewing to prevent weak seams from spreading across the batch.

- Stuffing weight verification Use digital scales to confirm filling weight matches sample standards.

- Embroidery and printing approval checks Confirm positioning, color accuracy, and clarity before scaling up decoration.

- Random mid-line sampling Inspect partially finished units during assembly to detect shape or structural issues early.

The advantage of in-line control is simple: problems are corrected immediately, not after thousands of units are completed.

| Control Stage | What Is Checked | Problem Prevented |

|---|---|---|

| Fabric stage | Color & pile | Surface inconsistency |

| Cutting stage | Pattern accuracy | Proportion errors |

| Sewing stage | Stitch strength | Structural weakness |

| Stuffing stage | Weight balance | Shape imbalance |

| Decoration stage | Alignment & clarity | Brand distortion |

| Mid-line sampling | Overall shape | Batch variation |

Without in-line quality control, defects multiply. With structured monitoring, defect rates drop dramatically and consistency improves.

At Kinwin, quality control is built into the process—not added at the end. Our QC team monitors production at defined checkpoints so that small deviations are corrected immediately. This protects both product quality and delivery timelines.

For buyers placing bulk orders, asking about in-line QC systems is one of the most effective ways to evaluate a factory’s professionalism.

Conclusion

Quality issues in plush toy production rarely come from one single mistake. Fabric control, pattern accuracy, stitching strength, stuffing consistency, decoration precision, and in-line monitoring all work together to protect product quality.

When these systems are strong, bulk production remains stable and predictable. When they are weak, small defects quickly become large problems.

Choosing a manufacturer with structured quality systems reduces risk, protects brand image, and ensures long-term customer satisfaction.

If you are evaluating plush suppliers or planning a new bulk order, our team at Kinwin is ready to support your project with transparent quality control and stable production processes.

Contact: [email protected]

Visit: https://kinwintoys.com