Material cutting is one of the earliest stages in plush toy production, yet it has one of the greatest impacts on the final outcome. The accuracy of each cut determines the toy’s shape, symmetry, softness, and character identity. For licensed characters, collectible plush, or high-end retail items, even a few millimeters of cutting deviation can dramatically alter proportions or visual appeal. When factories invest in precise cutting systems—combined with proper fabric handling and trained technicians—they create the foundation for consistent craftsmanship throughout mass production.

This article explains why cutting accuracy matters, how cutting precision influences sewing and assembly, and why brands should pay close attention to this often-overlooked stage in plush toy manufacturing.

How Accurate Cutting Ensures Proper Shape, Symmetry, and Character Proportions?

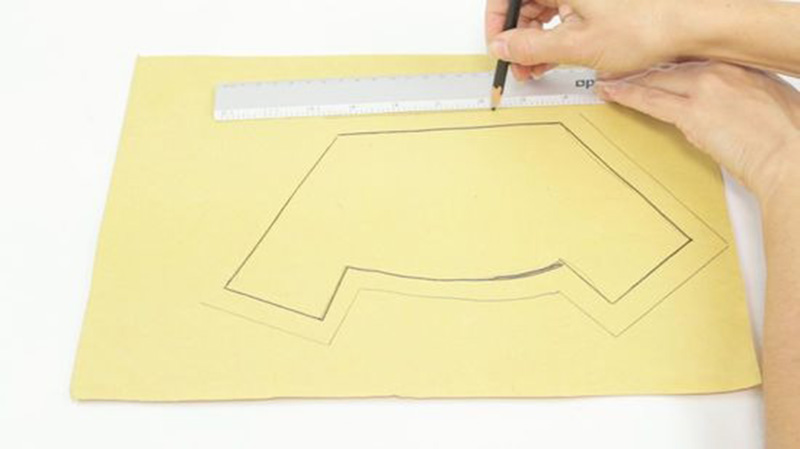

Accurate material cutting is essential for achieving perfect shape and symmetry in plush toys. Every plush design, whether simple or highly stylized, begins with pattern pieces that must be cut with precision. When these pieces deviate even slightly, the resulting toy may appear distorted—an oversized head, uneven limbs, or misaligned facial features. This is especially critical in character-based plush toys, where visual accuracy defines brand identity and consumer appeal.

During cutting, factory teams follow the pattern maker’s templates, ensuring each piece matches the intended size and shape. Consistency is vital because plush toys are three-dimensional objects; a small miscut in one panel can affect how the entire toy is sewn and stuffed. Precise cuts ensure that seams align correctly, stuffing fills evenly, and final proportions match the approved sample.

Accurate cutting also minimizes the risk of batch inconsistency. When hundreds or thousands of pieces are cut at once, variations can accumulate quickly, resulting in noticeable differences between units. Cutting precision ensures uniform appearance across an entire order.

Impact of Cutting on Shape & Symmetry

| Quality Aspect | Result of Accurate Cutting | Result of Inaccurate Cutting |

|---|---|---|

| Shape | Smooth, well-defined form | Misshapen or lumpy structure |

| Symmetry | Balanced limbs, features | Uneven sides or asymmetry |

| Character Accuracy | Matches approved sample | Distorted or off-model look |

| Seam Alignment | Clean stitching lines | Misaligned seams |

| Batch Consistency | Uniform appearance | High variation between units |

How Fabric Stretch, Pile Direction, and Grain Alignment Influence Cutting Precision?

Plush fabrics behave differently depending on their stretch, thickness, and pile direction. Cutting technicians must understand these material characteristics to ensure clean edges, proper alignment, and accurate shape retention during sewing.

Fabric stretch affects how patterns should be positioned. Stretchy fabrics like minky require stabilizing techniques and directional cutting to avoid distortion during assembly. If cut incorrectly, the toy can stretch unevenly or lose its intended proportions.

Pile direction (also called nap) is critical for visual appeal. Plush fabrics look different depending on whether the fibers face upward or downward. If pieces are cut without aligning pile direction, toys can appear patchy, with color or texture variations across different body parts.

Grain alignment ensures that fabric does not warp during sewing or stuffing. Cutting off-grain can cause twisting, skewing, or wrinkling in the final product.

Skilled cutters understand how fabric behaves under tension and how to position patterns to maximize both precision and appearance. Their work influences not only the toy’s shape but also its tactile and visual consistency.

Fabric Behavior Factors

| Fabric Property | Role in Cutting | Risk if Ignored |

|---|---|---|

| Stretch | Prevents distortion | Warped or elongated shape |

| Pile Direction | Ensures uniform surface look | Patchy or mismatched texture |

| Grain Alignment | Controls stability | Twisting or uneven seams |

| Thickness | Affects cutter blade choice | Ragged edges |

| Fabric Backing | Influences stiffness | Inaccurate shaping |

How Advanced Cutting Tools (Laser, Die-Cut, CNC) Improve Consistency Across Batches?

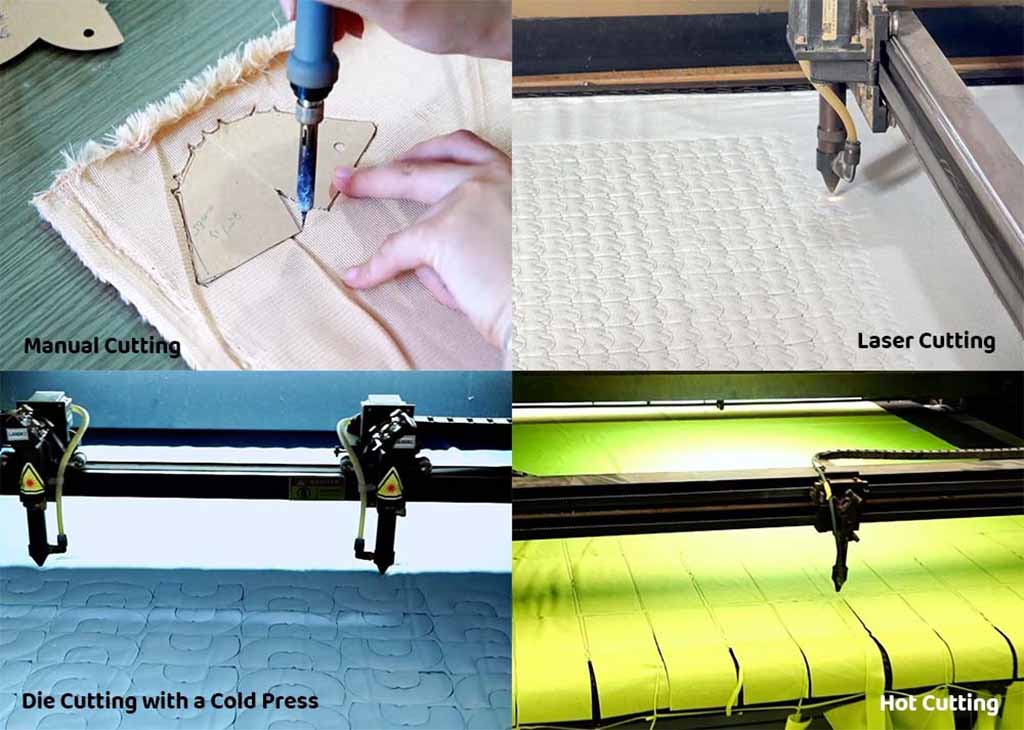

Modern plush toy factories increasingly rely on advanced cutting equipment to enhance accuracy, efficiency, and consistency. Traditional manual cutting methods can still produce excellent results, but they require highly skilled technicians and are more vulnerable to human error.

Laser cutting provides extremely precise edges and is ideal for intricate shapes or small components. It minimizes fraying and improves repeatability.

Die-cutting machines use metal molds to stamp out fabric shapes, producing high-volume pieces with uniform dimensions. They are perfect for mass production where consistency is essential.

CNC cutting systems (computer-controlled) automate complex patterns and ensure repeatable precision across hundreds of layers of fabric.

Automation reduces variations, speeds up production, and ensures pattern accuracy even for large orders with tight deadlines. These tools are especially valuable for brands requiring strict replication of character designs or premium craftsmanship.

Comparison of Cutting Technologies

| Cutting Method | Precision Level | Ideal Use Case | Benefit |

|---|---|---|---|

| Manual Cutting | Medium | Small batches, simple shapes | Flexible, low setup cost |

| Die Cutting | High | High-volume uniform parts | Excellent consistency |

| Laser Cutting | Very High | Detailed or small components | Clean edges, high accuracy |

| CNC Cutting | Very High | Complex patterns, multilayer | Fast & highly repeatable |

How Precise Cutting Reduces Sewing Difficulties, Distortion, and Assembly Errors?

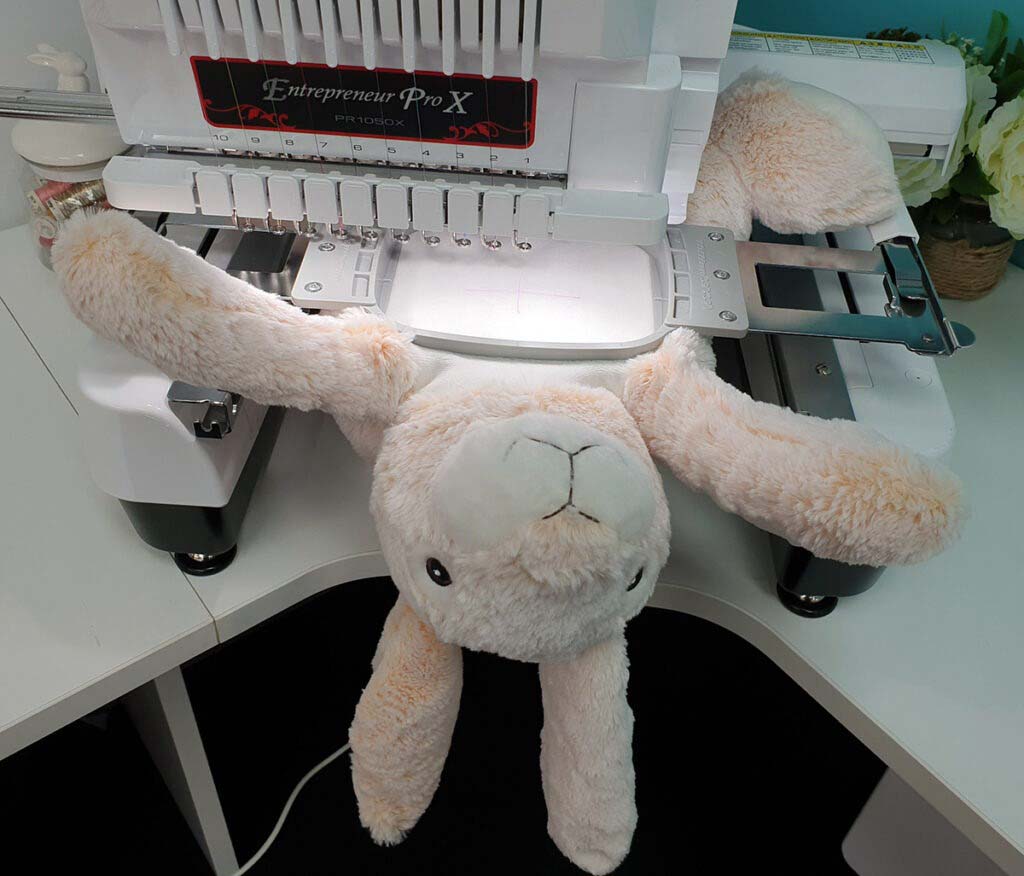

Precise cutting directly affects how smoothly parts assemble during sewing. When pieces are cut accurately, seam lines match perfectly, allowing workers to sew faster and with fewer adjustments. This reduces stress on fabric and minimizes the chance of puckering, stretching, or gaps.

When cutting is inaccurate, sewing teams must force pieces together, often stretching or trimming them manually to fit. This compromises seam durability and leads to production delays. Distorted pieces also create uneven stuffing distribution and incorrect proportions.

Accurate pattern cutting ensures that finished products align naturally with the Golden Sample, reducing rework rates and improving workflow efficiency. It also maintains consistency across different sewing shifts and workers, a crucial factor in mass production.

How Cutting Precision Supports Smooth Assembly

| Production Impact | With Accurate Cutting | With Inaccurate Cutting |

|---|---|---|

| Sewing Speed | Faster, more stable workflow | Slow, frequent adjustments |

| Seam Quality | Straight, strong seams | Weak or misaligned seams |

| Shape Retention | Matches intended design | Warping or uneven form |

| Worker Error | Minimizes human corrections | Increases risk of mistakes |

| Rework Rate | Very low | High due to mismatches |

How Efficient Cutting Layouts Reduce Material Waste and Improve Cost Control?

Beyond quality, cutting precision also affects production cost efficiency. Factories use fabric-cutting markers—optimized layouts that arrange pattern pieces to reduce fabric waste. Efficient cutting layouts can significantly lower material consumption, which is often the largest cost driver in plush toy manufacturing.

Factories with advanced marker planning software can analyze the best arrangement of patterns on fabric rolls to maximize usage. This allows buyers to save money without compromising product quality.

Accurate cutting also eliminates waste caused by mistakes, such as trimming errors or mismatched grain alignment. Combined with knowledgeable technicians, efficient layouts ensure cost control throughout mass production.

Material Optimization Table

| Optimization Factor | Benefit | Cost Impact |

|---|---|---|

| Marker Layout Efficiency | Reduces unused fabric | Lower material cost |

| Consistent Pattern Placement | Ensures uniform look | Fewer rejects |

| Correct Grain Alignment | Prevents distortion | Avoids re-cutting |

| Automated Cutting | Minimizes errors | Saves labor & materials |

| Waste Reduction | Less scrap produced | Higher profitability |

How Cutting Accuracy Supports High QC Standards in Mass Plush Toy Production?

Cutting is the foundation of every quality control checkpoint that comes after. When the initial fabric pieces are precise, QC teams can more easily detect irregularities in sewing, stuffing, and finishing. Uniform cuts allow inspectors to apply the same measurement standards across batches.

Cutting accuracy also supports:

- AQL inspections, because standardized parts reduce defect rates

- Safety tests, since well-made seams hold up better to tension

- Visual checks, because proportional consistency enhances appearance

- Final inspections, resulting in higher pass rates and fewer shipment delays

Factories that prioritize cutting precision usually demonstrate stronger overall QC performance because the reduced variability creates predictability throughout production.

QC Impact Table

| QC Area | Effect of Accurate Cutting | Benefit |

|---|---|---|

| AQL Sampling | Fewer dimension deviations | Higher pass rates |

| Safety Testing | Strong, even seams | Improved durability |

| Visual Inspection | Consistent appearance | Better retail acceptance |

| Batch Uniformity | Minimal variation | Strong brand consistency |

| Final Approval | Smooth inspection | Faster shipment release |

Conclusion

Material cutting is far more than an early production step—it is the foundation on which plush toy quality, consistency, and manufacturability depend. When factories invest in precise cutting methods, trained technicians, and high-quality tools, they reduce defects, improve efficiency, and ensure that every plush toy meets the designer’s original vision. For brands, understanding this stage is essential in selecting a reliable manufacturer and achieving top-tier results in mass production.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com