Branding is one of the most essential components of any plush toy, especially for companies aiming to build a recognizable identity or create a cohesive product line. Whether the goal is premium appearance, cost efficiency, or highly detailed artwork, the method used to apply your logo dramatically affects durability, visual impact, and manufacturability. Plush toys introduce unique challenges because their soft surfaces—sometimes long-pile, sometimes velvety smooth—interact differently with inks, threads, and heat-based transfers. This guide explores the strengths, limitations, and best-use scenarios of embroidery, printing, and heat transfer, helping you choose the ideal branding method for your plush toy project.

What Factors Determine the Most Suitable Logo Application Method for Plush Toys?

Selecting a logo method is not simply about aesthetics—it requires evaluating how the plush will be used, what materials it includes, how detailed the artwork is, and how the toy will be handled over time. Soft toys face constant friction, squeezing, washing, and stretching, which means the logo must maintain clarity and durability. Embroidery provides exceptional longevity but may not capture fine gradients. Printing allows detailed illustrations but depends heavily on the fabric surface. Heat transfer supports vibrant colors but requires a stable substrate for adherence.

Additional factors include safety requirements, color accuracy, brand positioning, and even the toy’s intended audience. For infant products, tactile safety and thread attachment strength matter most. For collectibles or licensed characters, accuracy of visual details becomes paramount. Understanding these elements ensures your branding method matches your product’s purpose and price point.

Key Factors Table

| Factor | Influence on Logo Method | Notes |

|---|---|---|

| Detail level | Printing / heat transfer handle fine lines | Embroidery suits simple shapes |

| Durability | Embroidery strongest | Printing durability varies |

| Fabric surface | Smooth surfaces favor printing | High pile favors embroidery |

| Brand positioning | Embroidery = premium | Printing = versatile |

| Budget | Printing often cheaper | Embroidery higher cost |

| Washability | Embroidery best | Some prints fade over time |

How Embroidery Enhances Durability, Texture, and Premium Brand Perception?

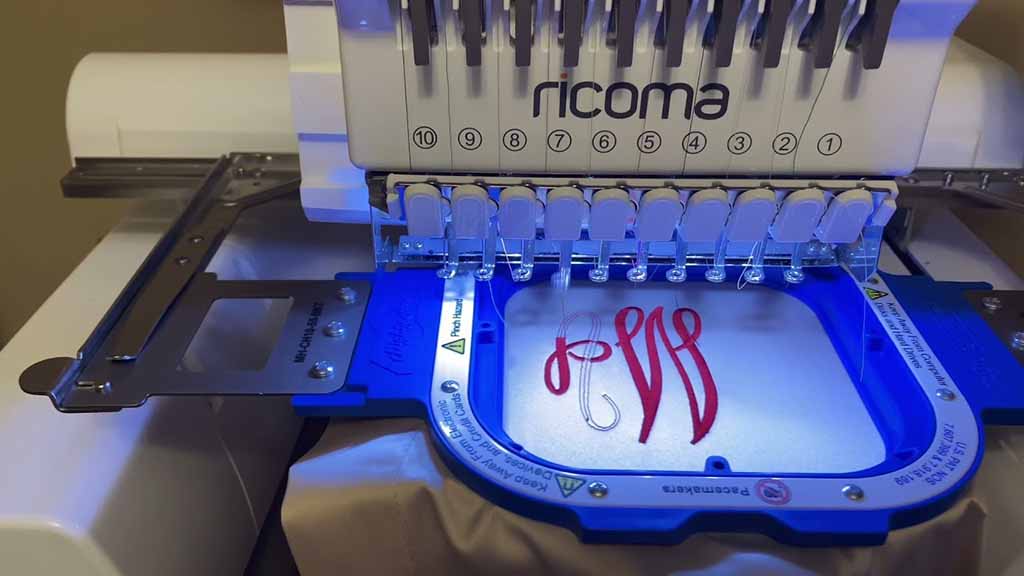

Embroidery is the most traditional and durable branding method for plush toys. Using high-density stitches, embroidery integrates threads directly into the fabric, resulting in a textured, elevated design that feels luxurious and long-lasting. It withstands repeated handling, stretching, and washing, making it ideal for plush toys intended for children or collections requiring extended use.

Embroidery also offers a premium, artisan-like look. The dimensional quality of thread brings depth to logos, making them tactile and visually striking. While embroidery excels with bold shapes, simple icons, and clean typography, it struggles with extremely thin lines or intricate gradients due to thread limitations. Factories may adjust your logo slightly to improve stitch quality, ensuring smooth curves and balanced composition.

Because embroidery requires specialized machines and thread color matching, production takes longer and costs more, especially for multicolor designs. However, the durability and premium feel make it a preferred choice for high-end plush brands, licensed characters, and retail-quality toys.

Embroidery Performance Overview

| Attribute | Strength | Consideration |

|---|---|---|

| Durability | Exceptional | Minimal risk of fading |

| Aesthetic | Premium, textured | Not ideal for subtle gradients |

| Safety | Very secure if stitched properly | Must follow pull-test standards |

| Application | Works well on most plush fabrics | Very long pile may obscure detail |

| Cost | Higher | Increases with colors & size |

How Screen Printing and Digital Printing Offer Flexibility for Detailed Artwork?

Printing opens the door to creative flexibility, especially for logos or artwork containing small details, shading, or multi-color elements. Screen printing works well for bold, flat colors, while digital printing captures photorealistic images, gradients, and subtle textures. These methods allow factories to reproduce intricate brand marks that embroidery simply cannot achieve.

Printing is most effective on smooth, short-pile fabrics such as velboa, tricot, or brushed polyester. When used on longer pile materials, details may blur or sink into the fibers. Factories often shave or flatten a designated print area to ensure clarity. Screen printing is durable but may crack slightly over time on stretch fabrics; digital printing retains detail but may fade depending on wash frequency and ink quality.

Printing is generally more cost-effective than embroidery, especially for large-area artwork. It also supports faster lead times and lower labor intensity. Because of its precision, printing is widely used in character-based plush, corporate giveaways, and plush toys with complex graphic elements.

Printing Feature Comparison

| Feature | Screen Printing | Digital Printing |

|---|---|---|

| Detail capability | Medium | Very high |

| Color vibrancy | Strong solids | Full-spectrum gradients |

| Durability | Good | Moderate |

| Cost | Medium-low | Medium |

| Best surface | Smooth fabrics | Smooth fabrics |

| Limitations | Not great for gradients | Requires high-quality fabric base |

How Heat Transfer Delivers Vibrant Colors and Sharp Lines on Plush Surfaces?

Heat transfer—especially modern methods like sublimation or vinyl transfer—offers crisp edges, vibrant colors, and consistent reproduction across large orders. Designs are printed onto a transfer sheet and bonded to the fabric using controlled heat and pressure. This ensures excellent accuracy even for logos with tight line work or intense color saturation.

Heat transfer works best on fabrics that can handle smooth bonding pressure, typically short-pile plush or flat-weave textiles. It is less suitable for very fluffy or uneven surfaces because the adhesive cannot bond evenly, leading to peeling or distortion. When the conditions are right, heat transfer provides impressive sharpness and a polished finish.

The method is ideal for medium-to-large logos where embroidery becomes too bulky or where printing would lose detail. It also allows for special finishes, such as metallic, neon, reflective, or glitter effects. However, long-term durability may be lower than embroidery, especially in high-friction areas.

Heat Transfer Evaluation Table

| Attribute | Performance Notes |

|---|---|

| Detail accuracy | Excellent for lines & shapes |

| Color quality | Vibrant and consistent |

| Durability | Moderate; depends on wash and usage |

| Compatibility | Best on smooth, stable fabrics |

| Cost | Medium; depends on sheet type |

| Special features | Metallics, holographic, textured finishes |

How Fabric Type, Surface Texture, and Pile Height Influence Logo Performance?

Fabric characteristics heavily determine which logo application method will succeed. High-pile plush such as faux fur or fluffy minky absorbs ink and obscures printed details. Long fibers may also interfere with heat transfer adhesion. Embroidery handles pile well because threads rise above the surface, maintaining visibility.

Short-pile fabrics or woven materials allow printing and heat transfers to bond smoothly. Patterns remain crisp and stable, making these fabrics ideal for detailed logos or gradient artwork. Stretchy fabrics require flexible inks or reinforced embroidery backing to prevent distortion.

Selecting the right method means balancing fabric behavior, logo complexity, and clarity expectations. Factories often test different techniques on swatches before choosing the final solution.

Fabric vs. Logo Method Suitability

| Fabric Type | Best Method | Why |

|---|---|---|

| Long-pile plush | Embroidery | Threads stay visible above pile |

| Short-pile velboa | Printing / heat transfer | Clean surface for sharp details |

| Minky | Embroidery or heat transfer | Printing may blur slightly |

| Woven labels | Printing or embroidery | Flat and stable |

| Stretch fabrics | Embroidery (with backing) | Prevents logo distortion |

How Cost, Lead Time, and Order Volume Affect the Choice of Logo Technique?

Pricing and production timelines vary significantly among embroidery, printing, and heat transfer. Embroidery generally costs more due to machine setup, thread consumption, and labor intensity. Printing is more budget-friendly for large batches, particularly if the design includes many colors. Heat transfer sits between the two, with additional costs depending on film type or special finishes.

Lead time is also a deciding factor. Printing usually offers the fastest turnaround because preparation is minimal. Embroidery takes longer and may slow mass production because each unit requires machine stitching. Heat transfer requires additional preparation but can be efficient once set up.

Order quantity is another practical concern. For small batches, embroidery or heat transfer may be preferable due to lower setup cost. For large-scale mass-market plush toys, printing often presents the most economical solution.

Cost & Lead Time Comparison

| Method | Cost Level | Lead Time | Best for |

|---|---|---|---|

| Embroidery | High | Medium–High | Premium brands, durability |

| Screen printing | Medium-Low | Fast | Large orders, bold art |

| Digital printing | Medium | Fast | Detailed artwork |

| Heat transfer | Medium | Medium | Vibrant logos, special finishes |

Conclusion

Choosing the right logo method for your plush toy is a strategic decision shaped by fabric type, brand identity, durability needs, artwork complexity, production volume, and budget. Embroidery offers premium texture and longevity, printing excels in detailed graphics, and heat transfer provides vibrant colors and precision. When paired with expert factory guidance and material testing, each method can elevate your plush product and strengthen your brand presence.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com