Launching a custom plush toy project requires clear, complete, and structured information from the very beginning. Factories rely heavily on the materials buyers provide—design files, dimensions, materials, branding details, safety requirements, and order expectations—to create accurate samples and predictable production outcomes. When buyers supply incomplete or ambiguous instructions, delays, misinterpretations, and cost increases often follow. But when you prepare a comprehensive information package, the development process becomes smoother, faster, and far more precise.

This guide explains the essential information factories need before they begin sampling or production, helping brands avoid miscommunication, achieve accurate prototypes, and maintain full control over cost, timing, and quality.

What Core Design Files and Visual References Are Required to Begin Development?

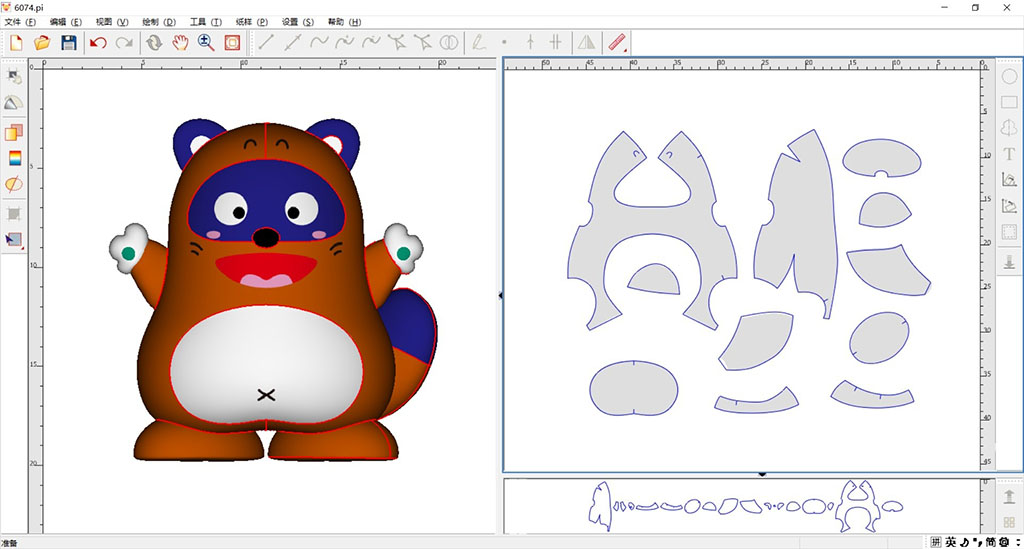

Every custom plush project begins with clear visual documentation. A factory cannot interpret a character accurately unless it receives complete and well-organized design files. The strongest starting point is a set of three-view drawings (front, side, back), but brands often include additional assets like 3D models, character sheets, color palettes, and pose references. These files help pattern makers understand the correct proportions, facial placement, silhouette, and personality of the character.

The more clarity you provide in the visual references, the fewer revisions you will need. For example, including facial close-ups prevents incorrect eye shapes or misplaced features. Providing color samples or Pantone codes avoids mismatched tones during sampling. Even simple plush projects benefit from mood boards, inspiration images, and previous product examples that communicate the intended style.

| Design Material | Purpose | Factory Benefit |

|---|---|---|

| 3-view drawings | Shows full body structure | Accurate pattern making |

| Character sheet | Displays expressions & proportions | Reduces facial errors |

| 3D model (optional) | Precise geometry reference | Helps with complex shapes |

| Pantone codes | Ensures color accuracy | Avoids mismatched dye lots |

| Close-up details | Clarifies small features | Improves embroidery & placement |

Without detailed visual references, factories must make their own interpretations—often leading to incorrect samples, additional costs, and project delays.

How Should Size, Proportions, and Structural Details Be Defined for Accuracy?

Size and proportion are not just measurements—they’re the foundation of the plush toy’s overall look and feel. Factories need to know the final standing or sitting height, the relative proportion of the head to the body, and any enlarged or stylized features. When these elements are undefined, the sample may appear “off-model,” even if the artwork is correct.

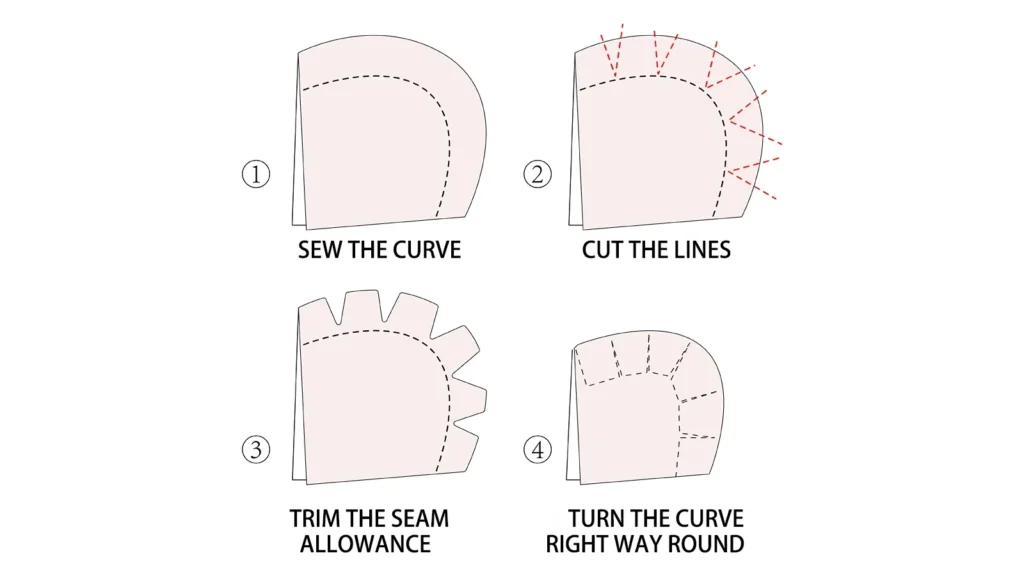

Factories also need structural details such as seam placement, thickness of limbs, body width, stuffing firmness, and whether weighted pellets, internal supports, or wire frames are required. Even small elements—such as tail stiffness, ear shape, or paw thickness—impact the final silhouette.

Complex shapes require more detailed specifications. For example, plush toys with oversized heads may need internal supports to prevent drooping. Dolls with very long limbs may require reinforced stitching. Characters with extreme curves or unusual geometry benefit significantly from additional diagrams or 3D references.

| Size/Structure Information | Why It Matters |

|---|---|

| Exact height | Determines pattern scale |

| Head-to-body ratio | Ensures correct character proportions |

| Arm/leg length | Affects symmetry & stability |

| Stuffing firmness | Influences feel & shape retention |

| Internal supports | Prevent sagging or deformation |

Clear structural details prevent misinterpretations that would otherwise require multiple costly revisions.

What Material Specifications, Fabrics, and Filling Requirements Must Be Provided?

Plush factories require precise material instructions to source the right fabrics and achieve the texture, softness, and appearance you want. Material selection impacts not only aesthetics but also durability, safety, and pricing. For example, minky offers luxurious softness, velboa provides firmness and clarity for small details, and faux fur creates volume and texture.

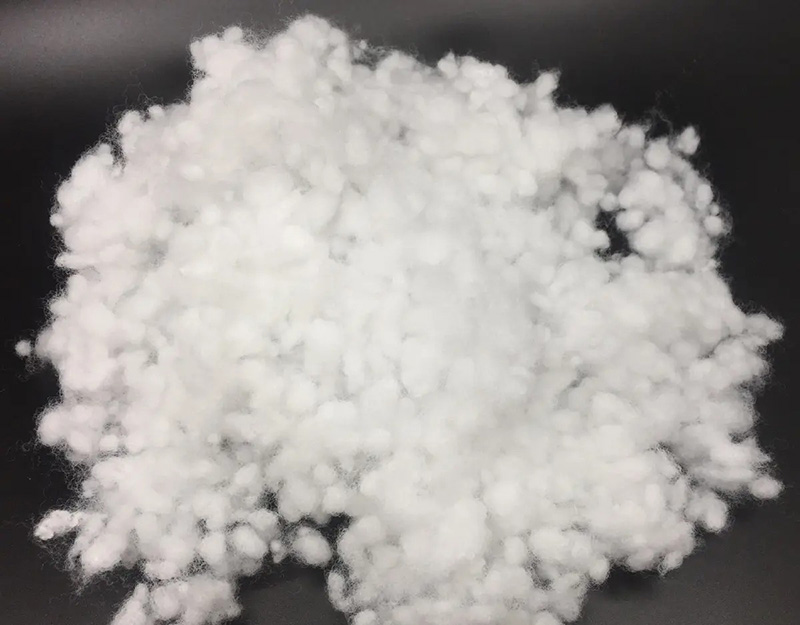

You should specify fabric types, pile height, density, and any special requirements like glitter fabric, metallic embroidery thread, or custom-dyed materials. Factories also need to know the preferred filling type, whether standard PP cotton, recycled polyester stuffing, weighted pellets, foam inserts, or specialty fillings.

Material mapping is critical—factories must know which fabric goes on which part of the toy, especially when mixing textures. Providing swatches or reference samples dramatically improves accuracy.

| Material Type | Characteristics | Best For |

|---|---|---|

| Minky | Soft, short pile | Baby toys, premium plush |

| Velboa | Durable, low-pile | Retail plush, sharp details |

| Faux fur | Voluminous, fluffy | Animals, fantasy creatures |

| Recycled polyester | Eco-friendly | Sustainable collections |

| Weighted pellets | Adds weight | Collectors, comfort plush |

Material clarity helps factories avoid sampling errors and ensures cost and feel match your expectations.

What Branding, Labeling, and Packaging Instructions Should Be Confirmed Upfront?

Brand identity must be incorporated from the very beginning. Factories need to know what labels, tags, packaging elements, or accessories your plush line requires. If branding details are provided too late, they can cause delays, resampling, or rush fees.

Your factory should receive clear instructions on:

- Woven label designs and placement

- Hang tag artwork, shape, and material

- Safety labels and country-of-origin tags

- Embroidered or printed brand logos

- Packaging format (polybag, box, window box, collector box)

- Barcodes, QR codes, and SKU information

Packaging must reflect the brand’s market positioning—retail, ecommerce, collectible, or promotional. Even the choice between a polybag and a premium display box can dramatically change cost structure and logistics planning.

| Branding Component | Factory Needs to Know | Impact |

|---|---|---|

| Woven labels | Size, font, placement | Prevents re-sewing errors |

| Hang tags | Artwork & thickness | Influences brand perception |

| Inner packaging | Polybag, tissue, box type | Affects cost & protection |

| Barcodes/SKUs | Format & location | Ensures retail compliance |

| Accessories | Ribbons, charms, props | Impacts assembly process |

Providing these elements early ensures smooth production and avoids last-minute changes.

What Safety, Compliance, and Testing Requirements Must Be Communicated Early?

Compliance requirements vary by market—U.S., EU, UK, Australia, Japan—and factories must know which regulations your plush toy must meet. Safety standards influence fabric choices, accessory types, seam strength, stuffing methods, and labeling requirements. Communicating these standards early prevents factories from selecting materials or construction methods that would later fail testing.

Factories typically need to know:

- Whether the toy is intended for children under 3

- Required certifications (ASTM F963, EN71, CPSIA, ISO 8124, etc.)

- Restrictions on detachable accessories

- Requirements for embroidery vs. plastic eyes

- Flammability and chemical testing standards

- Whether recycled materials must meet additional testing

Safety affects design from the inside out. For example, EU markets often prohibit small hard parts, while U.S. testing may scrutinize seam strength or stuffing accessibility. Without early communication, the sample may need to be rebuilt, adding weeks of delay.

| Compliance Requirement | Region | Influence on Design |

|---|---|---|

| ASTM F963 | USA | Eye safety, seam strength |

| EN71 | EU | Chemical limits, small parts |

| CPSIA | USA | Lead & phthalate controls |

| ISO 8124 | Global | Structural integrity |

| Age grading | All markets | Determines accessory usage |

How Do Quantity, Timeline, and Budget Expectations Shape Factory Planning?

Factories cannot plan production schedules, material sourcing, and labor allocation without knowing your expected order volume, target delivery date, and budget parameters. MOQ (minimum order quantity) directly affects pricing, fabric sourcing, and the factory’s ability to allocate production lines.

Early clarity on these three variables helps factories plan efficiently:

1. Quantity

- Determines bulk pricing

- Impacts fabric ordering (standard vs. custom dye lot)

- Influences whether automated or manual processes are used

2. Timeline

- Affects line scheduling

- Determines whether rush fees or overtime are required

- Influences shipping method (sea vs. air)

3. Budget Range

- Guides fabric selection (premium vs. economical)

- Determines accessory complexity

- Helps factories propose alternatives that stay within cost limits

| Planning Variable | Factory Impact |

|---|---|

| Order quantity | Affects MOQ, sourcing, cost |

| Delivery date | Determines line allocation |

| Budget target | Guides material & construction choices |

When factories understand your constraints early, they can provide realistic timelines, cost-optimized solutions, and stable production planning.

Conclusion

Clear communication is the foundation of every successful plush toy project. When brands provide complete design files, precise specifications, safety requirements, branding details, and realistic production expectations, factories can deliver faster sampling, more accurate prototypes, and consistent mass-production quality. Whether you’re a startup creating your first plush character or an established IP brand scaling a global product line, providing the right information is the most important step in achieving reliable, professional results.

At Kinwin, we specialize in turning well-defined briefs into high-quality, market-ready plush toys, supporting clients through every stage—from concept interpretation to production and logistics.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com