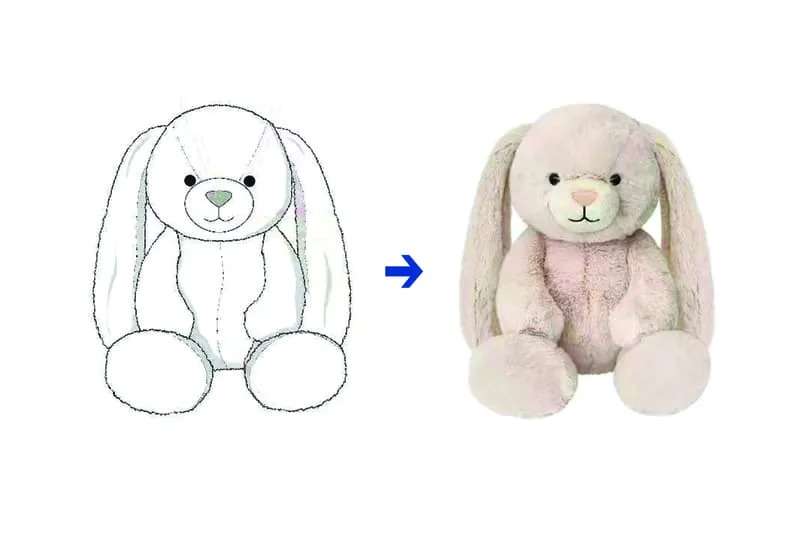

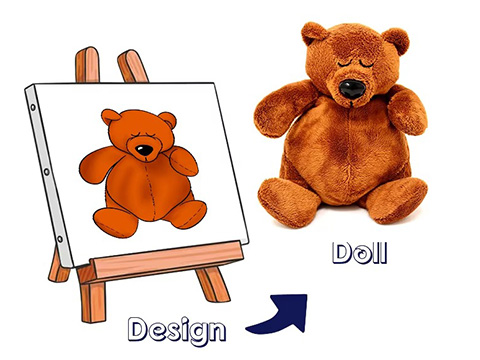

Many buyers feel confused or even disappointed when they receive a plush toy sample and notice it doesn’t look exactly like the original design. This reaction is very common—especially for first-time custom plush projects. From my experience, the issue is rarely about “poor workmanship” alone. More often, it comes from a gap between design expectations and how plush toys are physically made.

Plush toys are soft, three-dimensional products. Designs, on the other hand, are usually flat, stylized, or idealized. Understanding why differences happen is the first step to reducing frustration and improving sample accuracy.

Let’s start with the most fundamental reason.

Why Do 2D Designs and 3D Plush Samples Naturally Differ?

The most important thing to understand is this: a 2D design and a 3D plush toy are not created in the same language. Even a very detailed drawing cannot fully describe how fabric, stuffing, and seams behave in real life.

Key reasons this difference naturally occurs include:

- 2D designs show ideal shapes, not physical volume Illustrations usually present perfect proportions, smooth curves, and clean edges. Plush toys must contain stuffing, seams, and fabric thickness, which all change the final silhouette.

- Perspective and angles are simplified in drawings A front-view design may look balanced on paper, but once turned into a 3D object, side views, back views, and thickness become visible and affect proportions.

- Fabric adds thickness and softness Plush fabric is not a flat surface. Pile length, fabric density, and stretch all add volume that does not exist in a drawing.

- Stuffing creates internal pressure Once a plush toy is filled, the fabric stretches outward. This can slightly widen bodies, round faces, or shorten limbs compared to the original artwork.

- Seams interrupt smooth outlines In drawings, lines are continuous. In plush toys, seams are needed to connect fabric panels, and these seams subtly change curves and edges.

What buyers should realistically expect:

- Minor proportion changes are normal

- Rounded shapes will look softer than illustrated

- Sharp corners or thin details may appear thicker

- Symmetry may look different when viewed from multiple angles

This does not mean accuracy is impossible. It means accuracy must be managed, not assumed.

| Design vs Sample Factor | 2D Design | 3D Plush Sample | What Buyers Should Know |

|---|---|---|---|

| Shape definition | Flat, ideal | Rounded, soft | Volume changes appearance |

| Edges & corners | Sharp lines | Softer curves | Fabric adds thickness |

| Proportion control | Visual only | Physical constraints | Stuffing affects scale |

| Viewing angle | One perspective | All sides visible | Balance must work in 360° |

| Detail precision | Unlimited | Limited by fabric | Needs simplification |

For brands, recognizing this natural difference early helps set more realistic expectations during sampling. At Kinwin, we always start plush development by explaining how designs translate into physical form, so buyers understand which details can be matched closely and which need adjustment.

How Do Fabric Choice and Pile Direction Change the Final Appearance?

After moving from 2D to 3D, fabric choice is the next biggest reason why a plush sample may look different from the original design. Even when the pattern is accurate, the wrong fabric—or the right fabric used in the wrong way—can change how a plush toy looks at first glance.

This is especially true for plush toys because surface texture directly affects shape, color, and facial expression.

Key ways fabric choice influences appearance include:

- Pile length changes visual proportions

Long-pile fabrics (such as faux fur or long-pile minky) visually enlarge shapes and soften edges. Short-pile fabrics (like Velboa or Crystal Super Soft) keep outlines cleaner and closer to the design. - Fabric density affects shape definition

Dense fabrics hold shape better and show facial features more clearly. Loose or fluffy fabrics may blur details such as eyes, mouths, or printed elements. - Stretch and recovery alter dimensions

Some plush fabrics stretch more than expected during sewing and stuffing. This can widen bodies, shorten limbs, or slightly distort symmetry compared to the drawing. - Fabric shine changes color perception

Plush fabrics reflect light differently. The same color can appear lighter or darker depending on pile direction and lighting, making samples look “off-color” compared to flat artwork.

Pile direction (nap) is often overlooked but critical:

- Pile direction affects facial expression

If the nap runs upward on one side of the face and downward on the other, the plush can look uneven or “sad,” even if the pattern is correct. - Inconsistent nap makes colors look mismatched

Two panels cut in opposite pile directions may appear as different shades under light. - Pattern alignment becomes more difficult

Complex shapes require careful control of pile direction across all panels to maintain consistency.

Common buyer misunderstandings during sampling:

- “The color is wrong” (often caused by pile reflection)

- “The face looks different” (often caused by pile covering details)

- “The body feels bigger than expected” (often caused by fluffy fabric volume)

| Fabric Factor | What Changes | Impact on Sample Appearance |

|---|---|---|

| Pile length | Volume & softness | Alters perceived size |

| Fabric density | Shape clarity | Affects facial detail |

| Stretch | Final dimensions | Changes proportions |

| Surface reflection | Color tone | Appears lighter/darker |

| Pile direction | Visual balance | Affects symmetry |

For brands, the key takeaway is this: fabric is not just a material choice—it is a visual design decision. At Kinwin, we always review fabric type and pile direction during sampling, and we often recommend test panels or fabric swatches before full sample production to reduce surprises.

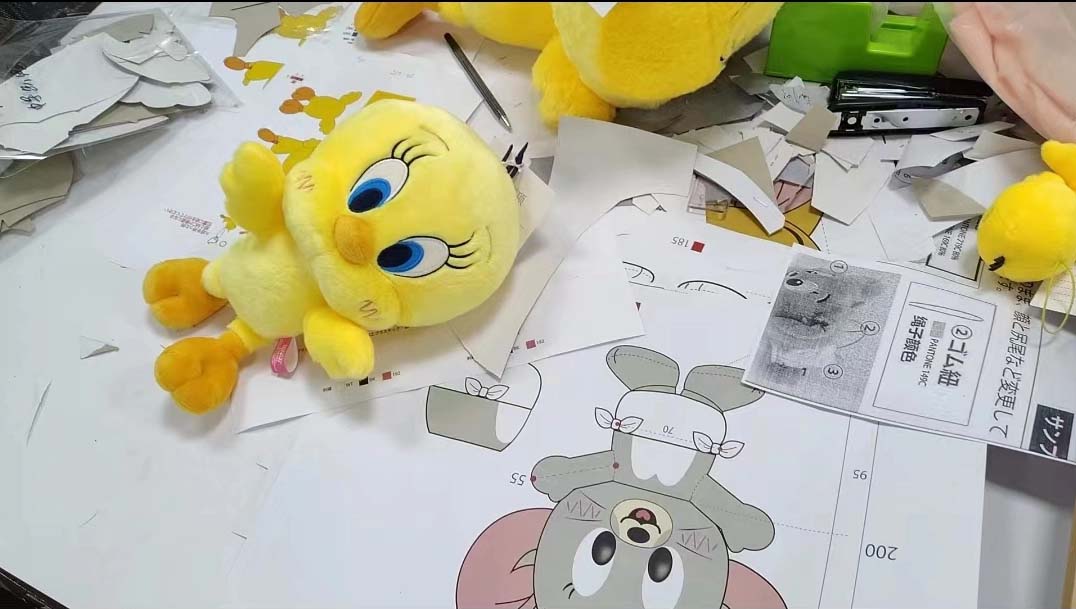

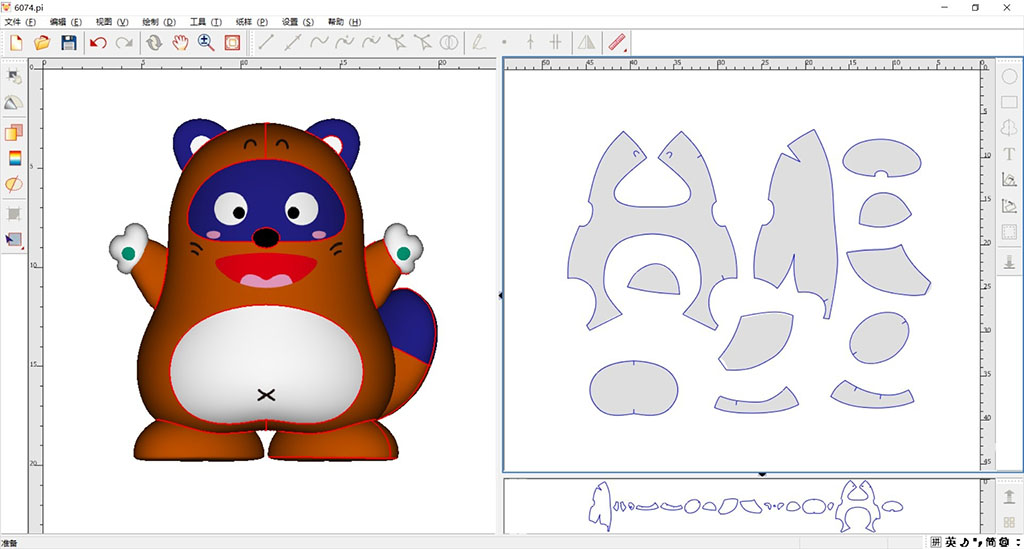

What Role Does Pattern Making Play in Sample Accuracy?

If fabric determines how a plush toy feels, then pattern making determines how it becomes real. From my experience, many sample differences that buyers notice are not caused by sewing quality or fabric choice, but by how the 2D design is translated into pattern pieces.

Pattern making is where artistic design meets manufacturing reality. This step decides structure, proportion, and balance long before the first stitch is sewn.

Key ways pattern making affects sample accuracy include:

- Designs must be broken into multiple fabric panels A flat illustration often looks like one smooth shape, but a plush toy needs many pattern pieces to form curves, thickness, and volume. Each seam slightly changes the outline compared to the drawing.

- Volume must be “calculated,” not guessed Pattern makers need to decide how much fabric is required to create a rounded face, belly, or limb. Too little volume makes the plush look flat; too much makes it bulky.

- Proportions change once depth is added A head that looks balanced in 2D may appear oversized or undersized once depth and stuffing are added. Pattern makers adjust proportions to make the plush look right in 3D, even if it differs slightly from the drawing.

- Symmetry is harder to achieve in soft structures Unlike plastic or hard toys, plush relies on fabric tension and stuffing. Pattern balance must account for how fabric stretches and settles after filling.

- Small design details may need structural support Thin arms, ears, or tails may need to be thickened or reshaped in the pattern to avoid collapsing or deforming over time.

Common buyer reactions during sampling—and what they usually mean:

- “The head feels too round” Often caused by added volume needed for stability and softness.

- “The arms look thicker than the drawing” Usually done to improve durability and prevent seam stress.

- “The proportions feel slightly different” Often an intentional adjustment to make the plush look better in real life.

| Pattern Making Decision | Why It’s Needed | How It Affects the Sample |

|---|---|---|

| Panel segmentation | Create 3D form | Changes outlines |

| Volume allowance | Support stuffing | Alters fullness |

| Proportion adjustment | Improve visual balance | Differs from artwork |

| Structural thickening | Increase durability | Less “thin” details |

| Seam placement | Shape control | Affects curves |

For brands, understanding pattern making helps shift the question from “Why doesn’t this match exactly?” to “Does this work better as a plush?”

At Kinwin, we always explain pattern logic during sampling so buyers understand why certain adjustments are necessary—and which ones can be fine-tuned in later revisions.

How Do Stitching, Seams, and Stuffing Affect Shape and Proportion?

Even when the pattern is correct, the way a plush toy is stitched and stuffed will still influence how the final sample looks. From my experience, many buyers underestimate how much seams and stuffing pressure can reshape a plush toy after it leaves the sewing table.

Plush toys are soft structures. Once fabric panels are joined and filled, the product naturally settles into a form that may differ from the flat design.

Key factors that affect shape and proportion include:

- Seam placement changes visual outlines Seams are not invisible. Where seams are placed—especially around the face, head, and body—will slightly change curves and edges compared to drawn lines.

- Stitch tension affects fabric stretch Tight stitching can pull fabric inward, making parts look smaller or more compact. Loose stitching may allow fabric to stretch outward after stuffing.

- Seam allowance adds thickness Seam allowances create internal bulk. In small areas like arms, ears, or facial contours, this extra thickness can noticeably alter proportions.

- Stuffing volume reshapes the silhouette Adding more stuffing creates rounder, fuller shapes. Less stuffing makes the plush flatter and softer. Even small changes in stuffing amount can change how tall, wide, or thick a plush appears.

- Stuffing distribution affects balance Uneven stuffing can cause heads to tilt, limbs to look shorter, or bodies to bulge in certain areas. Good stuffing control is essential for visual balance.

Common differences buyers notice during sample review:

- “The body looks wider than expected” Often caused by generous stuffing or fabric stretch during filling.

- “The face feels rounder than the drawing” A result of stuffing pressure pushing fabric outward from all sides.

- “The limbs look shorter” Happens when stuffing compresses fabric lengthwise.

- “The sample feels firmer than expected” Indicates higher stuffing density for durability or shape retention.

| Production Element | What Changes | Visual Result |

|---|---|---|

| Seam placement | Curve direction | Outline variation |

| Stitch tension | Fabric stretch | Size shift |

| Seam allowance | Internal bulk | Thicker appearance |

| Stuffing volume | Fullness | Rounder shapes |

| Stuffing balance | Weight distribution | Proportion changes |

For brands, this means sample accuracy is not only about matching the design, but about controlling physical forces inside the plush.

At Kinwin, we fine-tune stitching tension and stuffing density during sampling, and we always explain these adjustments so buyers understand how shape and proportion can be optimized without compromising durability.

Which Design Details Are Most Commonly Simplified During Sampling?

When buyers review a plush sample, they often notice that some small details look simpler than in the original design. This is not always a mistake. In many cases, it is a deliberate adjustment made during sampling to balance appearance, durability, safety, and production feasibility.

Understanding which details are commonly simplified helps brands focus feedback on what truly matters.

Design elements most often simplified include:

- Very thin or sharp details Elements like thin fingers, narrow ears, sharp spikes, or long whiskers may be thickened or shortened. Plush fabric and stuffing need minimum thickness to hold shape and survive handling.

- Highly complex facial expressions Fine lines, tiny mouth curves, or layered expressions in drawings may be simplified to ensure consistency across production and avoid distortion after stuffing.

- Small printed or embroidered details Very small logos, text, or fine line embroidery may lose clarity on plush fabric and are often enlarged or reduced in complexity.

- Layered fabric or overlapping elements Designs with many fabric layers can increase bulk and sewing difficulty. During sampling, some layers may be merged or removed.

- Decorative accessories Buttons, ribbons, or small attachments may be simplified or replaced to meet safety standards, especially for children’s products.

Why factories simplify these details during sampling:

- To ensure structural stability Plush toys need internal strength. Simplifying details often improves durability and reduces seam stress.

- To control production consistency Details that look fine in one sample may be difficult to repeat across hundreds or thousands of units.

- To meet safety and compliance requirements Small detachable parts or sharp shapes may pose choking or safety risks.

- To keep sampling and production efficient Overly complex details can significantly increase sample time and cost without adding proportional value.

| Design Detail | Why It’s Simplified | Benefit to the Product |

|---|---|---|

| Thin parts | Prevent collapse | Better durability |

| Fine facial lines | Avoid distortion | Cleaner expressions |

| Small embroidery | Improve clarity | Consistent branding |

| Multi-layer fabrics | Reduce bulk | Easier sewing |

| Accessories | Safety concerns | Compliance-ready |

For brands, the key is to distinguish between essential brand details and decorative elements. At Kinwin, we always highlight which details are critical to keep and which ones can be optimized, so buyers can make informed decisions instead of reacting to surprises.

How Can Brands Reduce Gaps Between Design Expectations and Plush Samples?

While differences between designs and samples are normal, large gaps are not inevitable. From my experience, brands that achieve high sample accuracy usually do three things well: they prepare clearer inputs, communicate earlier, and collaborate closely during development.

Practical ways brands can reduce gaps include:

- Provide more than one design reference A single front-view illustration leaves too much open to interpretation. Side views, back views, color references, and similar plush examples help factories understand intent more clearly.

- Define “must-keep” details early Not every detail has equal importance. Brands should clearly mark which elements are non-negotiable (logo shape, eye style, proportions) and which can be optimized.

- Discuss fabric and texture during design review Fabric choice should be aligned before sampling starts. This avoids redesign caused by unexpected pile behavior or softness differences.

- Accept small structural adjustments for better results Some changes improve durability, balance, and long-term quality. Brands that focus on the final feel and look in real life usually get better outcomes than those chasing 1:1 drawings.

- Use feedback rounds efficiently Clear, structured feedback—rather than emotional reactions—helps pattern makers adjust faster and more accurately.

- Work with manufacturers experienced in plush translation Factories that regularly convert artwork into plush understand where problems appear and how to prevent them early.

| Action Area | Brand Behavior | Result on Sample Accuracy |

|---|---|---|

| Design input | Multi-angle references | Fewer assumptions |

| Priority setting | Clear must-haves | Focused revisions |

| Fabric planning | Early confirmation | Fewer visual surprises |

| Structural flexibility | Practical mindset | Better plush balance |

| Feedback method | Clear & specific | Faster improvements |

| Factory selection | Plush expertise | Higher success rate |

At Kinwin, we treat sampling as a collaborative process, not a one-time output. By aligning expectations early and guiding brands through each adjustment, we help close the gap between design intent and plush reality—without unnecessary delays or cost.

Conclusion

Plush toy samples often look different from original designs not because something went wrong, but because plush toys follow physical rules that drawings do not. Fabric behavior, pattern structure, stitching, stuffing, and safety considerations all reshape how a design comes to life.

When brands understand these factors and work closely with experienced plush manufacturers, sample differences become manageable—and often lead to better final products. With the right preparation and communication, design intent and plush reality can align far more closely than most buyers expect.

If you’re developing a custom plush project and want higher sample accuracy from the start, our team at Kinwin is always ready to help.

Contact: [email protected]

Visit: https://kinwintoys.com