In stuffed toy manufacturing, sample accuracy is not a cosmetic issue—it is a predictor of mass-production risk. From my experience working with OEM and ODM buyers, factories that fail at sampling rarely recover during bulk production, no matter how competitive the price looks.

Buyers often judge samples emotionally: “It looks close enough.” Professional evaluation is different. Sample accuracy must be assessed against design intent, structure logic, material behavior, and repeatability. This is especially critical for brands, licensed products, and retail programs that require consistency.

Before analyzing patterns, materials, or tolerances, buyers must first understand what “sample accuracy” actually means in professional stuffed toy manufacturing, because definitions vary widely between factories.

What Defines “Sample Accuracy” in Professional Stuffed Toy Manufacturing?

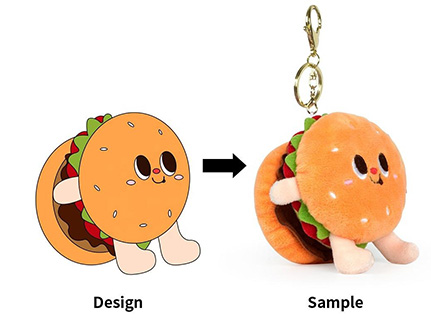

Sample accuracy is not about making something that looks similar. From my experience, professional factories define sample accuracy as how precisely a physical sample translates the original design intent into a manufacturable, repeatable product.

At a basic level, sample accuracy includes visual similarity—shape, expression, proportions, and overall feel compared to the artwork or reference sample. However, professional evaluation goes much deeper. Structural accuracy matters just as much. This includes internal construction logic, seam placement, symmetry, and how the toy holds its form when handled.

Another critical factor is dimensional consistency. A sample may look correct in photos but fail when measured. Professional factories control height, width, and depth within defined tolerances, especially for products that must fit packaging, displays, or regulatory size limits.

Material behavior is also part of accuracy. Fabrics stretch, compress, and reflect color differently than digital artwork. Accurate samples account for these behaviors instead of hiding them temporarily for approval.

Finally, true sample accuracy includes repeatability. A factory that can make one good-looking sample but cannot explain how to reproduce it consistently has not achieved professional accuracy.

| Accuracy Dimension | Superficial Interpretation | Professional Definition | Buyer Impact |

|---|---|---|---|

| Visual appearance | “Looks similar” | Proportion & expression matched | Brand consistency |

| Structural build | Hidden inside | Logical & repeatable | Production stability |

| Dimensions | Approximate size | Controlled measurements | Packaging fit |

| Material behavior | Ignored | Predicted & managed | Quality reliability |

| Repeatability | One-off success | Process-based result | Scale confidence |

For buyers, understanding this definition changes how samples are judged. Manufacturers that talk about **process, structure, and control—not just appearance—**are far more likely to deliver accurate bulk production after sample approval.

How Do Pattern Making and Structural Design Affect Sample-to-Design Consistency?

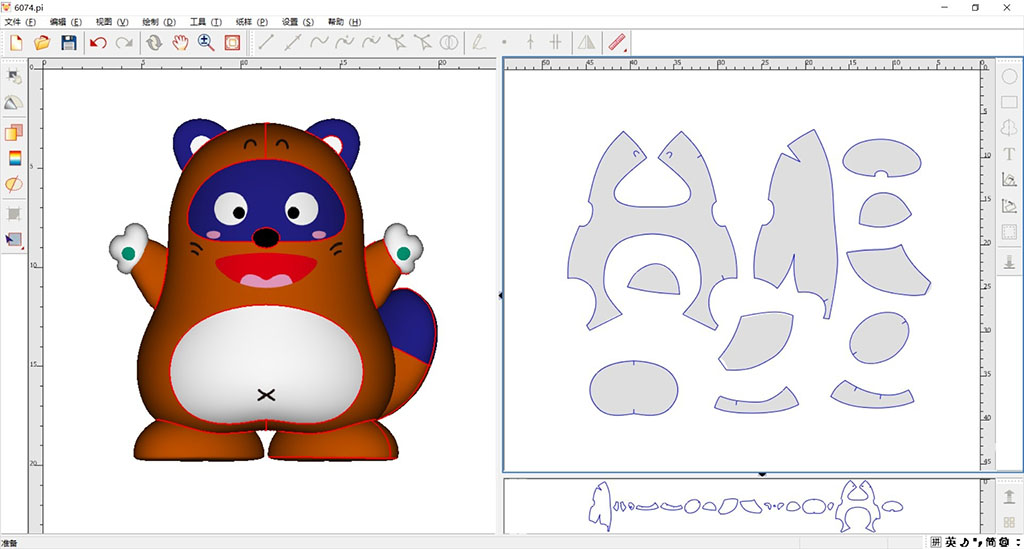

In stuffed toy sampling, pattern making is where accuracy is either built—or lost. From my experience, many factories focus too much on surface details and ignore the structural translation from artwork to 3D form. This is why some samples look acceptable from one angle but collapse or distort when handled.

Professional pattern making starts with breaking the design into functional zones. Head, body, limbs, and feature areas are patterned separately based on volume, seam direction, and fabric behavior. Accurate factories do not trace artwork directly; they interpret it into three-dimensional geometry that can be sewn and filled consistently.

Structural design also determines symmetry and balance. Poor internal structure leads to twisted heads, uneven limbs, or unstable sitting posture. Strong factories design internal seam paths and stuffing distribution deliberately, so the plush holds its shape without overstuffing.

Another key factor is pattern scalability. Accurate factories create patterns that can be scaled up or down without changing proportions. This is critical for brands that need multiple sizes from the same design. If a factory cannot explain how patterns are adjusted for size changes, accuracy risk increases.

Finally, professional pattern teams document revisions. Each sample change is reflected in updated patterns, not just verbal notes. This ensures consistency between approved samples and later production.

| Pattern Factor | Weak Practice | Professional Practice | Accuracy Outcome |

|---|---|---|---|

| Artwork translation | Direct tracing | 3D structural interpretation | Shape consistency |

| Seam logic | Random placement | Purpose-driven seams | Stable form |

| Symmetry control | Visual correction | Pattern-based balance | Repeatable accuracy |

| Size scalability | Manual resizing | Proportional pattern grading | Multi-size consistency |

| Revision control | Verbal changes | Documented pattern updates | Production alignment |

For buyers, pattern quality is invisible—but its results are not. Factories that invest in experienced pattern makers and structured design logic are far more likely to deliver samples that stay accurate from first prototype through mass production.

What Visual and Dimensional Details Should Be Checked Against Original Artwork?

When evaluating sample accuracy, buyers should move beyond overall likeness and focus on specific, measurable details. From my experience, many disputes happen because buyers approve samples emotionally, while factories interpret accuracy visually instead of dimensionally.

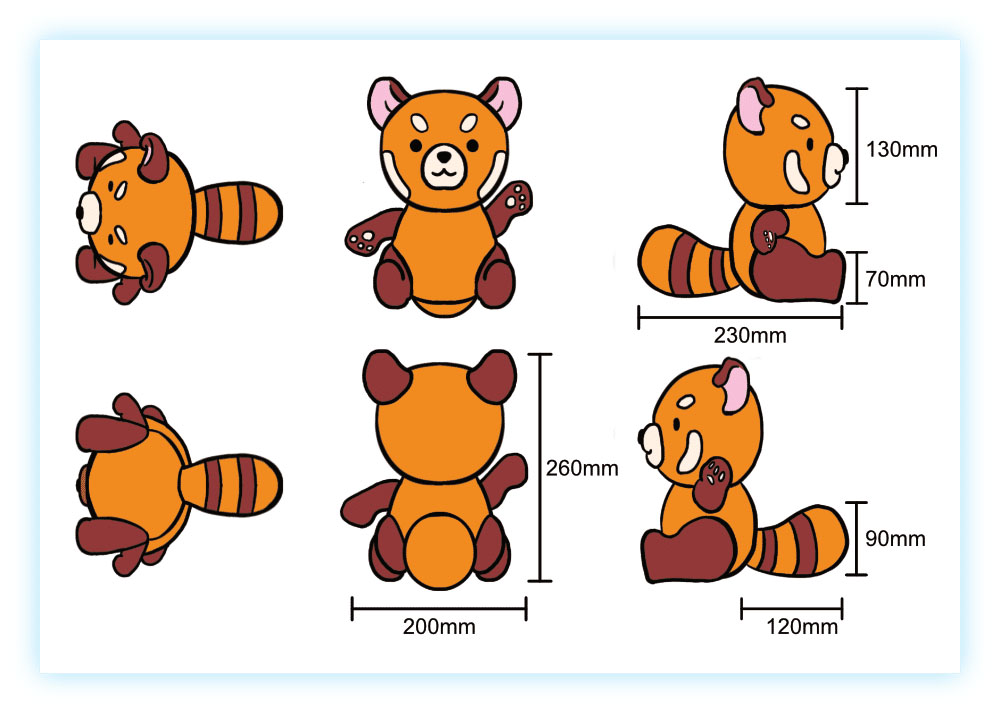

The first area to check is proportion balance. Head-to-body ratio, limb length, and feature spacing should match the original artwork or reference sample. Even small deviations can change the character’s personality or perceived age, which is especially critical for licensed or branded plush toys.

Next, examine facial details closely. Eye position, embroidery scale, mouth curvature, and expression symmetry must align with the design intent. These details are often where accuracy drifts, because fabrics stretch and embroidery density changes during sewing.

Dimensional checks are equally important. Buyers should measure overall height, width, and depth, then compare them with design specifications or tolerance ranges. This is not about perfection—it is about controlled deviation. Professional factories can explain why slight differences occur and whether they are consistent across samples.

Another key check is volume distribution. Stuffing should support the intended shape without distortion. Overstuffing may hide pattern errors in samples but creates problems during bulk production.

Finally, assess consistency from multiple angles. Rotate the sample, place it flat, and observe how it holds form. Accurate samples look correct from all views, not just the front.

| Check Area | Common Oversight | Professional Evaluation | Buyer Benefit |

|---|---|---|---|

| Proportion | Visual guess | Ratio comparison | Character integrity |

| Facial alignment | Front view only | Multi-angle check | Expression accuracy |

| Dimensions | Ignored | Measured & recorded | Packaging fit |

| Stuffing volume | Overfilled sample | Balanced structure | Production stability |

| Overall form | One-angle approval | 360° consistency | Fewer revisions |

For buyers, checking these details turns sample review into objective evaluation. Factories that welcome measurement, explain deviations, and document changes demonstrate a much stronger ability to deliver accurate samples at scale.

How Do Material Selection and Color Matching Impact Final Sample Accuracy?

Material choice and color matching are two of the most underestimated factors in sample accuracy. From my experience, many samples fail not because the pattern is wrong, but because the selected materials behave differently from what the design assumes.

Fabrics define surface texture, stretch, pile direction, and light reflection. A plush fabric with longer pile can soften edges and blur shapes, while short pile fabrics show structure more clearly. If the fabric behavior is not considered during pattern making, even a correct pattern can produce an inaccurate-looking sample.

Color matching adds another layer of complexity. Digital artwork colors rarely translate directly to fabric. Dye lots, fabric base color, and pile direction all influence how a color appears. Professional factories do not rely on screen colors alone. They compare physical swatches under controlled lighting and explain acceptable color deviation ranges in advance.

Material density also affects volume accuracy. The same pattern can look larger or smaller depending on fabric thickness and filling rebound. Accurate factories adjust stuffing logic based on material properties instead of forcing volume through overfilling.

Another key point is material consistency. A sample made with “close enough” fabric may pass visual approval but fail in bulk when the actual production material behaves differently. Reliable factories insist on using production-intended materials as early as possible.

| Material Factor | Inaccurate Practice | Professional Control | Accuracy Result |

|---|---|---|---|

| Fabric type | Chosen for appearance | Chosen for behavior | Shape stability |

| Pile direction | Ignored | Controlled & aligned | Visual consistency |

| Color matching | Screen-based | Swatch & light-tested | Brand accuracy |

| Fabric thickness | Compensated by stuffing | Pattern-adjusted | Volume control |

| Material consistency | Sample-only fabric | Production-intended | Scale reliability |

For buyers, material discussions reveal a factory’s depth of experience. Manufacturers that proactively explain why a material affects shape, color, and repeatability are far more capable of delivering accurate samples—and consistent bulk production afterward.

What Tolerance Levels Are Acceptable Between Approved Samples and Design Files?

No physical stuffed toy can match a design file at 100%. From my experience, professional sample accuracy is not about zero deviation—it is about controlled, explainable, and repeatable tolerance. Buyers who expect absolute precision often face delays, while buyers who accept uncontrolled deviation face bigger risks later.

Acceptable tolerance starts with dimension ranges. Height, width, and depth usually allow small percentage-based variation, depending on size and fabric type. For medium-sized plush toys, controlled deviations are normal, but they must be consistent and documented. A factory that cannot define its tolerance range is not controlling accuracy.

Visual tolerance is equally important. Facial features, embroidery placement, and expression symmetry allow far less flexibility than body volume. Even a few millimeters of shift in eye position can change character identity. Professional factories clearly separate critical visual points from flexible areas.

Material-related tolerance must also be understood. Fabric stretch, pile direction, and filling rebound naturally affect final appearance. Accurate factories explain which differences are material-driven and which require pattern correction—rather than hiding them during approval.

Most importantly, tolerance must be repeatable. If three samples show three different deviations, accuracy is unstable. If all samples fall within the same controlled range, the factory demonstrates process control.

| Tolerance Area | Uncontrolled Situation | Professional Control | Buyer Confidence |

|---|---|---|---|

| Overall dimensions | Undefined variation | Pre-defined range | Packaging fit |

| Facial features | Visual guessing | Fixed reference points | Brand consistency |

| Body volume | Overstuffed correction | Pattern-based control | Stable shape |

| Material behavior | Ignored impact | Explained deviation | Predictable outcome |

| Repeatability | Sample-to-sample drift | Consistent tolerance | Scale readiness |

For buyers, accepting tolerance does not mean lowering standards. It means working with factories that understand where deviation is acceptable, where it is not, and how to keep it consistent from sample approval through mass production.

How Can Revision Cycles and Communication Efficiency Reflect a Factory’s Accuracy Capability?

Sample accuracy is not proven by the first prototype—it is proven by how efficiently a factory improves accuracy through revisions. From my experience, revision cycles reveal more about a factory’s capability than any single sample ever could.

The first signal is how feedback is received and translated. Accurate factories do not just acknowledge comments; they restate issues clearly, confirm priorities, and explain how changes will be implemented. This shows they understand both design intent and production logic.

Revision speed also matters, but speed alone is not enough. A fast revision that introduces new problems indicates weak internal coordination. Professional factories balance speed with precision, making targeted changes without affecting previously approved details.

Another critical factor is change traceability. Reliable factories track what was changed, why it was changed, and how it affects patterns, materials, or structure. This documentation prevents repeated mistakes and keeps sample development aligned with future production.

Communication clarity is equally important. Factories with strong accuracy capability communicate in visuals, measurements, and comparisons—not vague language. They may provide side-by-side photos, measurement tables, or marked-up artwork to show exactly what was adjusted.

Finally, watch for revision convergence. Accurate factories reduce deviation with each round. If revisions move closer to approval instead of drifting, the factory demonstrates control and learning ability.

| Revision Signal | Weak Accuracy Indicator | Strong Accuracy Indicator | Buyer Advantage |

|---|---|---|---|

| Feedback handling | Generic responses | Clear restatement & plan | Fewer misunderstandings |

| Revision speed | Fast but unstable | Controlled & targeted | Predictable progress |

| Change tracking | No records | Documented revisions | Production alignment |

| Communication style | Descriptive only | Visual & measurable | Clear evaluation |

| Revision trend | Repeated drift | Converging accuracy | Approval confidence |

For buyers, revision cycles are a live test of accuracy capability. Factories that listen precisely, revise intentionally, and communicate clearly are far more likely to deliver samples—and bulk production—that match approved standards consistently.

Conclusion

Evaluating sample accuracy requires more than visual judgment. Buyers who assess structure, materials, tolerances, and revision discipline can identify factories capable of delivering consistent, scalable stuffed toy production with confidence.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com