Trade shows remain one of the most effective environments for evaluating plush toy suppliers—not because of the number of booths, but because they allow buyers to observe products, people, and processes simultaneously. Unlike online sourcing, trade shows reveal how suppliers present themselves under pressure, how consistently they explain their capabilities, and how prepared they are to support real OEM and ODM projects. For B2B buyers, the key is approaching trade shows with clear evaluation logic, not relying on first impressions alone.

What Preparation and Evaluation Criteria Should Buyers Define Before Attending Trade Shows?

The effectiveness of supplier evaluation at trade shows depends heavily on pre-show preparation. Buyers who arrive without clear criteria often leave with brochures but no reliable conclusions. Before attending, buyers should define what type of supplier they are actually looking for: OEM-focused, ODM-capable, character/IP experienced, or cost-driven mass production. Each category requires different evaluation priorities.

Clear preparation also helps buyers manage time. Trade shows are intense environments, and without predefined criteria, it is easy to spend time on visually attractive booths that are strategically irrelevant. Buyers should prepare a checklist covering product category fit, customization depth, compliance experience, and production scale. This transforms booth visits from casual conversations into structured assessments.

Another important preparation step is understanding your own project constraints. Knowing target MOQ, budget range, certification requirements, and market destinations allows buyers to quickly filter suppliers who are not a realistic match, even if their products look impressive.

| Preparation Area | Why It Matters | Buyer Action |

|---|---|---|

| Product category focus | Avoids misaligned suppliers | Define core plush types |

| OEM vs ODM needs | Determines design depth | Clarify development role |

| Compliance markets | Impacts documentation | List target regions |

| MOQ & scale | Filters factories | Set realistic ranges |

| Time allocation | Improves efficiency | Pre-plan booth priorities |

How Can Product Samples and Displays Reveal a Supplier’s Real Manufacturing Capability?

At trade shows, product samples tell far more truth than brochures. Buyers should look beyond surface softness or cuteness and evaluate construction consistency, finishing quality, and design logic across multiple samples. A booth displaying many styles with consistent stitching, shape control, and fabric quality often reflects stable production systems.

Display structure also reveals capability. Suppliers that can clearly group samples by category, technique, or material usually have better internal organization. Mixed or chaotic displays may indicate trading behavior rather than true manufacturing control. Buyers should pay attention to seams, embroidery alignment, symmetry, and how complex designs are executed.

Importantly, buyers should ask whether displayed samples are mass-production replicas or showroom-only pieces. Factories with real manufacturing strength can explain how a sample translates into bulk production, including pattern adjustments and quality tolerance.

| Sample Indicator | What It Reveals | Buyer Observation |

|---|---|---|

| Stitch consistency | Production control | Check multiple units |

| Embroidery accuracy | Skill level | Look for alignment |

| Fabric handling | Material experience | Feel & recovery |

| Design repetition | Scalability | Similar quality across styles |

| Display logic | Organization | Category-based layout |

What Questions Help Assess Customization, OEM/ODM Experience, and Design Support?

Trade shows offer a rare chance to test how suppliers think, not just what they show. Asking the right questions reveals whether a supplier understands real customization workflows or simply accepts orders passively. Buyers should ask how the supplier handles sketches, revisions, and material substitutions.

ODM capability is especially easy to exaggerate. A genuine ODM supplier can explain how they support concept development, trend research, and structural optimization—not just modify existing designs. Asking for real examples of past OEM or ODM projects helps distinguish experience from claims.

Design support is also reflected in communication clarity. Suppliers who can explain pattern-making logic, cost impact of design changes, and risk points during sampling usually offer stronger long-term collaboration.

| Key Question Area | What It Tests | Strong Supplier Response |

|---|---|---|

| Customization scope | OEM depth | Explains process steps |

| ODM examples | True design ability | Shares real cases |

| Revision handling | Project management | Clear iteration logic |

| Cost-impact awareness | Commercial thinking | Explains trade-offs |

| Design team role | Support capacity | Dedicated pattern makers |

How Do Certifications, Test Reports, and Compliance Documents Indicate Supplier Reliability?

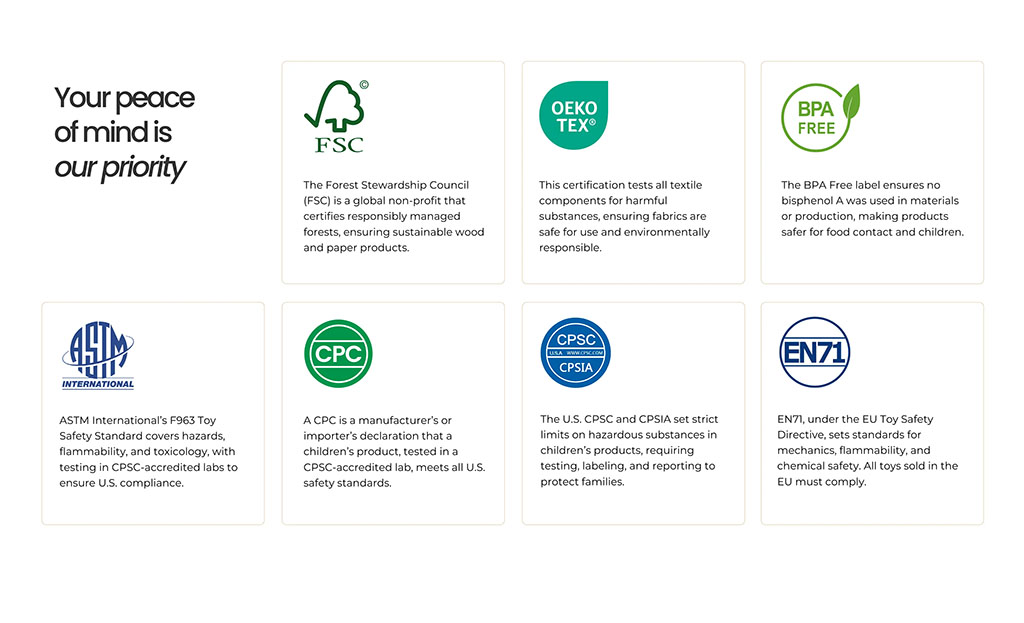

Compliance discussion at trade shows is not about collecting certificates—it is about understanding how deeply compliance is integrated into operations. Reliable suppliers can clearly explain which standards they work with, how often they test, and how they support buyers during audits or customs checks.

Buyers should ask to see recent test reports, not just certificates. Reports with clear lab names, dates, and product references show active compliance management. Vague or outdated documents suggest risk. Suppliers familiar with multiple markets (USA, EU, Japan) usually demonstrate stronger internal systems.

Another key indicator is how suppliers discuss non-compliance. Factories with real experience will openly explain past issues and corrective actions, rather than claiming zero problems.

| Compliance Indicator | What It Signals | Buyer Evaluation |

|---|---|---|

| Recent test reports | Active compliance | Check dates & scope |

| Market-specific standards | Export experience | Multi-region familiarity |

| Lab cooperation | Testing readiness | Named labs |

| Issue handling | Transparency | Clear corrective process |

| Documentation clarity | Reliability | Organized explanations |

How Can Buyers Evaluate Communication Skills, Responsiveness, and Professionalism On-Site?

Trade shows are ideal for evaluating human factors that are difficult to assess online. Buyers should observe how suppliers listen, respond, and explain—not just how fluent their English is. Professional suppliers ask clarifying questions, confirm understanding, and avoid overpromising.

Responsiveness can be tested directly. Buyers may ask for follow-up materials, sample photos, or technical answers during the show. How quickly and accurately suppliers respond provides insight into future project collaboration.

Professionalism is also reflected in internal coordination. Suppliers who consult team members confidently, rather than giving vague answers, usually have clearer internal processes.

| Interaction Signal | What It Reveals | Buyer Test |

|---|---|---|

| Listening quality | Client focus | Note clarification questions |

| Answer structure | Process maturity | Logical explanations |

| Response speed | Reliability | Request follow-up |

| Internal coordination | Team strength | Observe consultations |

| Promise control | Risk awareness | Avoids guarantees |

How Should Post-Show Follow-Ups and Factory Verification Confirm the Right Supplier Choice?

The real evaluation begins after the trade show ends. Serious buyers should narrow suppliers to a short list and conduct structured follow-ups. This includes requesting detailed quotations, sample timelines, and compliance documents tailored to the buyer’s actual project.

Factory verification is essential. Virtual tours, audit reports, or on-site visits confirm whether trade show impressions align with reality. Buyers should verify production lines, QC checkpoints, and sample development workflows.

Post-show communication quality often predicts long-term success. Suppliers who remain consistent, responsive, and transparent after the event are far more likely to perform well during actual production.

| Post-Show Step | Purpose | Buyer Action |

|---|---|---|

| Quotation review | Cost realism | Compare detail levels |

| Sample request | Execution check | Evaluate accuracy |

| Factory verification | Risk control | Audit or visit |

| Document confirmation | Compliance readiness | Match target market |

| Communication tracking | Partnership fit | Observe consistency |

Conclusion

Trade shows are powerful sourcing tools only when buyers apply structured evaluation logic. By preparing clear criteria, analyzing samples critically, asking the right questions, and verifying suppliers after the show, buyers can transform trade show meetings into reliable, long-term manufacturing partnerships.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com