Importing stuffed animals from China can deliver strong cost and supply-chain advantages, but quality consistency remains one of the biggest concerns for global buyers. From unclear specifications to weak communication and insufficient inspections, many quality issues occur long before goods reach the port.

Based on years of working with international brands and retailers, ensuring quality is not about relying on a single inspection step. It requires a systematic approach—from pre-order standards, factory evaluation, sampling control, in-line inspections, to long-term supplier management. This guide breaks down the key stages buyers must manage to protect product quality when sourcing stuffed animals from China.

What Quality Standards and Specifications Should Be Defined Before Placing Orders?

Before importing stuffed animals from China, the most critical quality-control step happens before any order is placed. Many quality problems do not originate in the factory—they originate from unclear or incomplete standards defined by the buyer. Without precise specifications, factories will default to their internal norms, which may not match your market expectations or regulatory requirements.

The first layer of definition is product-level quality standards. This includes size tolerance, weight range, stitching density, seam strength, embroidery accuracy, fabric pile direction, and filling consistency. Stuffed animals are tactile products, so even small variations in softness, firmness, or proportion can affect perceived quality. Buyers should define acceptable tolerance ranges in writing rather than relying on vague instructions such as “same as sample.”

The second layer involves material and component specifications. Fabric type, fiber composition, filling material, accessory construction (eyes, noses, labels), and color standards must be documented clearly. For example, specifying “100% polyester plush” is not enough—pile length, fabric weight (GSM), colorfastness, and shedding limits should also be included. The same applies to fillings, where density, rebound performance, and safety compliance directly affect product performance.

The third layer is market-specific compliance and performance requirements. Different markets apply different safety and labeling rules. These requirements must be converted into measurable, factory-executable standards, rather than just referencing regulation names.

Well-defined standards reduce subjective judgment, minimize disputes, and create a shared quality language between buyer and factory.

| Quality Area | What Should Be Defined | Why It Matters | Common Risk If Missing |

|---|---|---|---|

| Dimensions & weight | Tolerance range | Consistent appearance | Size variation |

| Materials | Fabric GSM, fiber type | Touch & durability | Inconsistent softness |

| Stitching | SPI, seam strength | Product longevity | Seam failure |

| Filling | Density & rebound | Shape retention | Lumpy feel |

| Compliance | Target market standards | Import approval | Shipment rejection |

How Can Buyers Evaluate Stuffed Animal Factories Beyond Online Claims?

Relying solely on factory websites, Alibaba profiles, or marketing brochures is one of the most common mistakes buyers make when sourcing stuffed animals from China. Online information often highlights best-case scenarios, but it rarely reflects a factory’s actual production discipline, quality consistency, or problem-solving ability. To evaluate factories effectively, buyers need to look beyond surface claims and focus on verifiable signals.

The first area to assess is production focus and specialization. A factory that produces plush toys as its core business usually has more stable stitching teams, material handling routines, and internal quality benchmarks than a general soft goods factory. Buyers should ask what percentage of the factory’s output is stuffed animals, what product types dominate their production, and how long they have served export markets similar to yours.

The second area is process visibility. Reliable factories can clearly explain how orders move from sampling to mass production. This includes pattern approval, material preparation, cutting, sewing, stuffing, internal inspection, and packing. If explanations are vague or overly simplified, it often indicates weak internal control or a trading-company-style operation rather than true manufacturing ownership.

Another critical factor is evidence-based validation. Instead of accepting claims like “high quality” or “export standard,” buyers should request real proof: recent production photos, sample-to-bulk comparison cases, internal QC checklists, or references to long-term overseas clients. How a factory responds to detailed questions often reveals more than the answers themselves.

Finally, communication behavior during evaluation matters. Factories that respond clearly, admit limitations, and ask clarifying questions tend to be more reliable long-term partners than those that overpromise or avoid specifics.

| Evaluation Area | What Buyers Should Check | Why It Matters | Risk if Ignored |

|---|---|---|---|

| Product focus | % of plush output | Process maturity | Inconsistent quality |

| Process clarity | Step-by-step workflow | Predictable results | Hidden production gaps |

| Proof materials | Photos, samples, records | Claim verification | Misleading capabilities |

| Client experience | Export market history | Market fit | Compliance mismatch |

| Communication | Accuracy & transparency | Issue prevention | Escalation delays |

What Role Do Sampling, Pre-Production Approval, and PPS Play in Quality Control?

Sampling and pre-production approval form the bridge between design intent and mass production reality. For stuffed animals, this stage is especially critical because softness, proportion, stitching quality, and overall “feel” cannot be fully specified by documents alone. Without disciplined sampling control, even well-defined standards can break down once bulk production starts.

The first step is the initial development sample, which tests whether the factory can correctly interpret design files, reference images, and specifications. At this stage, buyers should focus on overall proportions, facial expression accuracy, material choice, and construction logic. The goal is not perfection, but feasibility and alignment. Any misunderstanding discovered here is far cheaper to fix than during production.

Once revisions are complete, the pre-production sample (PPS) becomes the most important physical reference for quality control. The PPS must be produced using the same materials, processes, and workmanship that will be used for mass production. Buyers should treat the PPS as a contractual quality benchmark. Every future inspection—inline or final—should be measured against this approved sample.

Pre-production approval is not only about aesthetics. It also confirms process stability. If a factory struggles to reproduce the approved sample consistently, this signals potential risks during scaling. Buyers should document PPS approval clearly, including photos, comments, and sign-off records, to avoid disputes later.

| Stage | Purpose | Buyer Focus | Risk if Skipped |

|---|---|---|---|

| Development sample | Feasibility check | Proportion, structure, look | Misinterpreted design |

| Revision cycle | Alignment | Details & corrections | Repeated defects |

| PPS | Mass-production reference | Materials & workmanship | Bulk inconsistency |

| Approval record | Quality benchmark | Traceability | Disputes during claims |

Sampling is not a formality—it is a quality control gate. When managed correctly, it reduces production risk, shortens inspection time, and creates a shared quality reference that both buyer and factory can rely on throughout the order.

How Do In-Line Inspections and AQL Standards Prevent Mass Production Issues?

Once stuffed animal production enters the mass-production stage, quality risks shift from design interpretation to process execution and consistency. At this point, waiting until final inspection is often too late. In-line inspections, combined with clearly defined AQL standards, are essential tools to detect problems early and prevent small defects from turning into large-scale losses.

In-line inspection focuses on monitoring production while it is happening, rather than judging results after completion. For stuffed animals, this usually includes checking cutting accuracy, stitching density, seam strength, embroidery placement, stuffing uniformity, and component attachment. These inspections are typically conducted when 10–30% of production is completed, allowing corrective actions before defects spread across the entire order.

AQL (Acceptable Quality Limit) standards provide a statistical framework to evaluate whether a production batch meets agreed quality levels. Instead of inspecting every unit, inspectors sample a defined quantity based on order size and apply acceptance criteria for critical, major, and minor defects. For buyers, agreeing on AQL levels in advance removes subjectivity and ensures both sides evaluate quality using the same benchmark.

The real value of in-line inspection is not rejection—it is process correction. When defects are identified early, factories can adjust sewing methods, retrain workers, or replace materials before costs escalate. Buyers who rely only on final inspection often face difficult decisions: accept compromised quality or delay shipment. In-line inspection significantly reduces this risk.

| Control Tool | What Is Checked | When It Happens | Benefit |

|---|---|---|---|

| In-line inspection | Stitching, stuffing, assembly | During production | Early defect detection |

| Process check | Work methods & tools | Mid-production | Prevents repeat errors |

| AQL sampling | Defect rates | Inline & final stages | Objective quality judgment |

| Defect grading | Critical / Major / Minor | Inspection phase | Clear pass/fail criteria |

| Feedback loop | Corrective actions | Immediately after findings | Stabilizes output |

Effective use of in-line inspections and AQL standards turns quality control into a continuous process, not a last-minute checkpoint. For buyers importing stuffed animals from China, this approach is one of the most reliable ways to protect timelines, reduce rework, and maintain consistent product quality across large volumes.

What Safety Testing, Certifications, and Compliance Checks Are Essential for Importing?

Safety testing and regulatory compliance are non-negotiable when importing stuffed animals from China. Even when a product looks visually perfect, failure to meet safety or chemical standards can result in shipment detention, recalls, fines, or permanent loss of market access. For buyers, compliance is not just a legal requirement—it is a core part of quality assurance.

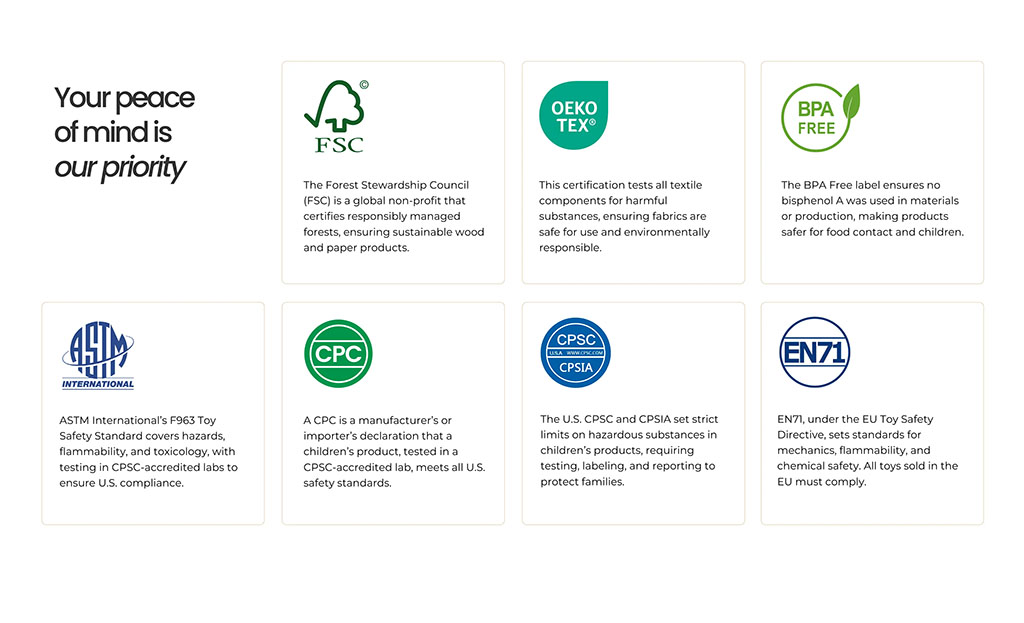

The first layer of compliance involves market-specific toy safety standards. For example, stuffed animals sold in the U.S. must comply with ASTM F963 and CPSIA requirements, while products entering the EU must meet EN71 standards and CE marking obligations. These standards cover mechanical safety, flammability, chemical content, and labeling requirements. Buyers must confirm which standards apply to their exact product category and target age group before testing begins.

The second layer is material and component testing. Fabrics, fillings, threads, prints, and accessories such as eyes or labels may each require separate chemical testing. Recycled or dyed materials, in particular, need careful screening for restricted substances. Testing should be conducted through accredited third-party laboratories, and reports must be current and traceable to the production batch.

The third layer involves documentation and traceability checks. Test reports alone are not enough. Buyers should ensure that product descriptions, photos, SKU references, and factory information match exactly across all documents. Any mismatch can raise red flags during customs clearance or retailer audits.

Finally, compliance is not a one-time action. Changes in materials, suppliers, or production processes can invalidate previous test reports. Ongoing compliance monitoring is essential for consistent quality and uninterrupted imports.

| Compliance Area | What Is Required | Purpose | Risk if Overlooked |

|---|---|---|---|

| Toy safety standards | ASTM, EN71, CPSIA, etc. | Legal market access | Shipment rejection |

| Chemical testing | Fabrics, fillings, prints | Consumer safety | Product recalls |

| Lab accreditation | ISO/recognized labs | Report credibility | Invalid test reports |

| Documentation match | SKU, photos, specs | Traceability | Customs delays |

| Ongoing review | Material/process changes | Continuous compliance | Compliance lapse |

When safety testing and compliance checks are integrated into the quality-control workflow, buyers reduce both regulatory risk and commercial uncertainty. For stuffed animal imports, this step protects not only the shipment, but also brand reputation and long-term market stability.

How Can Clear Communication and Long-Term Supplier Management Ensure Consistent Quality?

For buyers importing stuffed animals from China, quality consistency is rarely achieved through inspections alone. In practice, long-term quality stability depends heavily on clear communication systems and disciplined supplier management. Even capable factories can deliver inconsistent results if expectations, feedback, and responsibilities are not managed in a structured way.

Clear communication starts with unambiguous instructions and documentation. Buyers should avoid relying on casual chat messages or assumptions based on previous orders. Specifications, revisions, approvals, and inspection feedback should be documented clearly and shared with all relevant factory teams, including production supervisors and QC staff—not only sales contacts. This reduces the risk of information loss as projects move from development to mass production.

Equally important is feedback quality and timing. When issues arise, vague comments such as “quality not good” provide little value. Effective buyers reference specific defects, affected quantities, and comparison points (for example, PPS vs. bulk). Timely feedback allows factories to adjust processes before problems repeat across future orders.

Long-term supplier management also involves performance tracking. Buyers should evaluate factories not only on price and delivery, but also on defect rates, responsiveness, corrective actions, and consistency over time. Sharing performance expectations openly helps align priorities and encourages factories to invest in process improvements rather than short-term fixes.

Finally, stable partnerships create incentives for quality investment. Factories are more willing to assign experienced workers, maintain material consistency, and prioritize problem-solving when they see predictable order volume and long-term cooperation. This relationship-driven approach often delivers better quality outcomes than switching suppliers frequently in search of marginal cost savings.

| Management Area | What Buyers Should Do | Quality Impact | Risk if Ignored |

|---|---|---|---|

| Communication | Document specs & changes | Fewer misunderstandings | Repeated errors |

| Feedback | Specific, timely reporting | Faster corrections | Defect repetition |

| Performance tracking | Monitor quality metrics | Continuous improvement | Declining standards |

| Relationship building | Long-term planning | Priority production | Low factory commitment |

| Process alignment | Involve QC & supervisors | Consistent execution | Info gaps |

Conclusion

Ensuring quality when importing stuffed animals from China requires more than inspections at the end of production. By defining clear standards, carefully evaluating factories, controlling sampling and pre-production approvals, implementing in-line inspections, managing compliance, and building strong long-term supplier relationships, buyers can reduce risk and achieve consistent, market-ready product quality at scale.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com