For many brands, the sampling stage is the most stressful part of plush toy development. Designs look great on screen, but once the sample arrives, small differences quickly raise questions: Is this accurate enough? Can this be fixed? Will production look the same?

From my experience, sample accuracy is not about chasing perfection in one round. It is about setting the right standards, processes, and expectations so that designs can be translated into plush products in a controlled and repeatable way. Once brands understand what “accuracy” really means in plush manufacturing, the entire development process becomes much more predictable.

Let’s start by defining what sample accuracy actually means in this industry.

What Does “Sample Accuracy” Mean in Plush Toy Manufacturing?

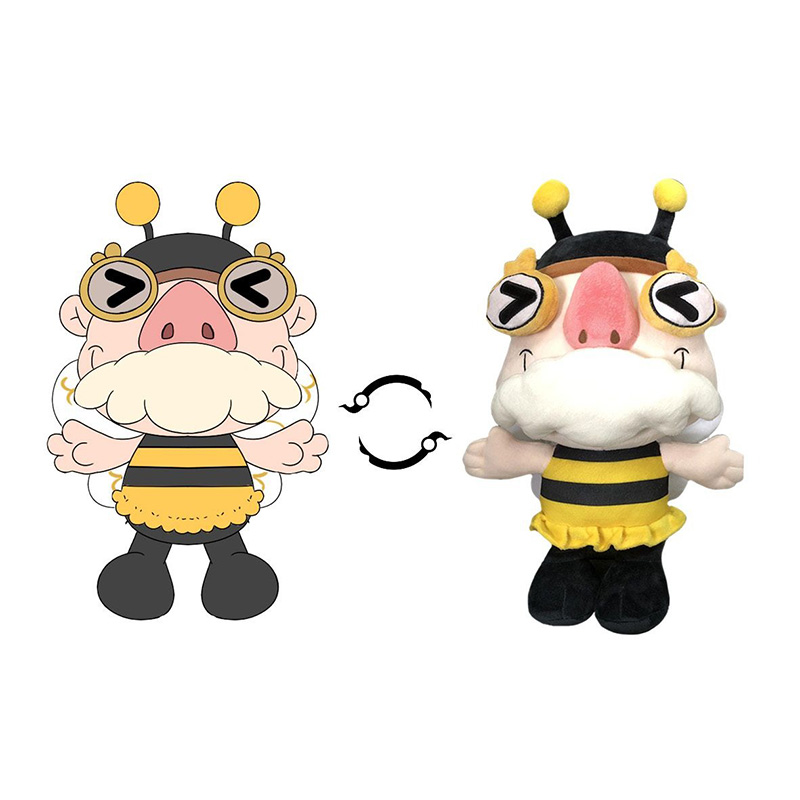

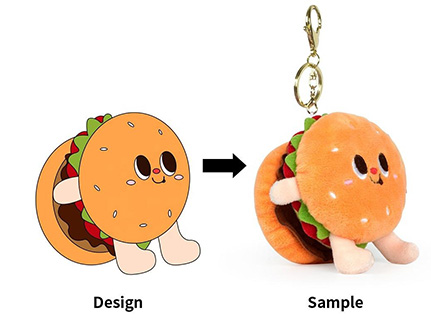

Sample accuracy in plush toy manufacturing does not mean a sample looks exactly the same as a flat drawing or digital rendering. Plush toys are soft, three-dimensional products made from fabric, seams, and stuffing. Accuracy is about how closely the sample reflects the design intent within physical and production limits.

In real manufacturing terms, sample accuracy usually includes several layers.

Key elements that define sample accuracy include:

- Overall shape and proportion The plush should visually match the intended body ratio, head size, limb length, and balance when viewed from multiple angles, not just the front.

- Key design features Facial expression, eye style, ear placement, tail shape, or signature elements should clearly reflect the original concept, even if small adjustments are made.

- Material alignment The fabric type, texture, and color tone should align with what was agreed during development, not substituted without explanation.

- Functional structure The sample should stand, sit, or hold shape as intended, without collapsing or deforming due to poor internal structure.

- Production feasibility An accurate sample must also be repeatable. A beautiful one-off sample that cannot be consistently produced is not considered “accurate” in a professional sense.

Common misunderstandings buyers have about sample accuracy:

- Expecting a 1:1 match to a flat illustration

- Judging accuracy from only one viewing angle

- Focusing on small visual differences while ignoring structural improvements

- Assuming accuracy is fixed after the first sample

| Accuracy Aspect | What It Really Means | Why It Matters |

|---|---|---|

| Visual match | Close to design intent | Brand recognition |

| Proportion | Balanced in 3D | Natural appearance |

| Material use | As agreed | Predictable results |

| Structure | Holds shape | Durability |

| Repeatability | Can be mass-produced | Production safety |

For brands, defining sample accuracy clearly at the beginning helps avoid emotional reactions and misaligned expectations later. At Kinwin, we always align with clients on what accuracy means for their specific product, so feedback stays focused and productive.

How Do Design Files and Reference Materials Affect Sample Results?

In plush toy development, sample accuracy often depends less on craftsmanship and more on the quality of information provided before sampling starts. From my experience, many sample issues come from unclear or incomplete design inputs rather than factory mistakes.

Plush manufacturers do not “see” your idea the way you do. They rely entirely on the files and references you provide to interpret shape, proportion, texture, and priorities.

Key ways design files and references affect sample accuracy include:

- Level of detail in the main design file Simple sketches or stylized drawings leave room for interpretation. Clear outlines, labeled parts, and proportion notes reduce guesswork during pattern making.

- Availability of multiple views A single front view rarely explains thickness, back shape, or side profile. Side and back views help pattern makers build balanced 3D structures.

- Clear indication of scale Without size references or measurements, factories must estimate proportions. Even small misjudgments can affect how “accurate” a plush feels when held.

- Reference images of similar plush toys Photos of existing plush products help translate artistic intent into manufacturable form, especially for facial expressions and body posture.

- Priority guidance on key features When everything is treated as equally important, factories may miss what truly defines the character. Clear “must-keep” details guide better decisions.

- Consistency across files Conflicting information between drawings, notes, and messages can lead to inconsistent sample results.

Common issues caused by weak design inputs:

- Facial expression feels off despite correct sewing

- Body proportions look different from expectations

- Fabric texture does not match imagined appearance

- Small details are over- or under-emphasized

| Design Input Area | Weak Input | Strong Input | Impact on Accuracy |

|---|---|---|---|

| Main artwork | Stylized only | Clear outlines | Better interpretation |

| Viewing angles | Front view only | Multi-angle views | Balanced 3D form |

| Size reference | No measurements | Defined scale | Correct proportions |

| Reference products | None provided | Similar plush examples | Faster alignment |

| Feature priority | Unclear | Must-keep noted | Focused accuracy |

| File consistency | Mixed messages | Aligned files | Fewer revisions |

For brands, improving sample accuracy often starts before sampling begins. At Kinwin, we review design files together with clients and highlight missing or unclear information early, so pattern making and sampling can move forward with fewer assumptions.

How Does Pattern Making Determine Plush Shape and Proportion?

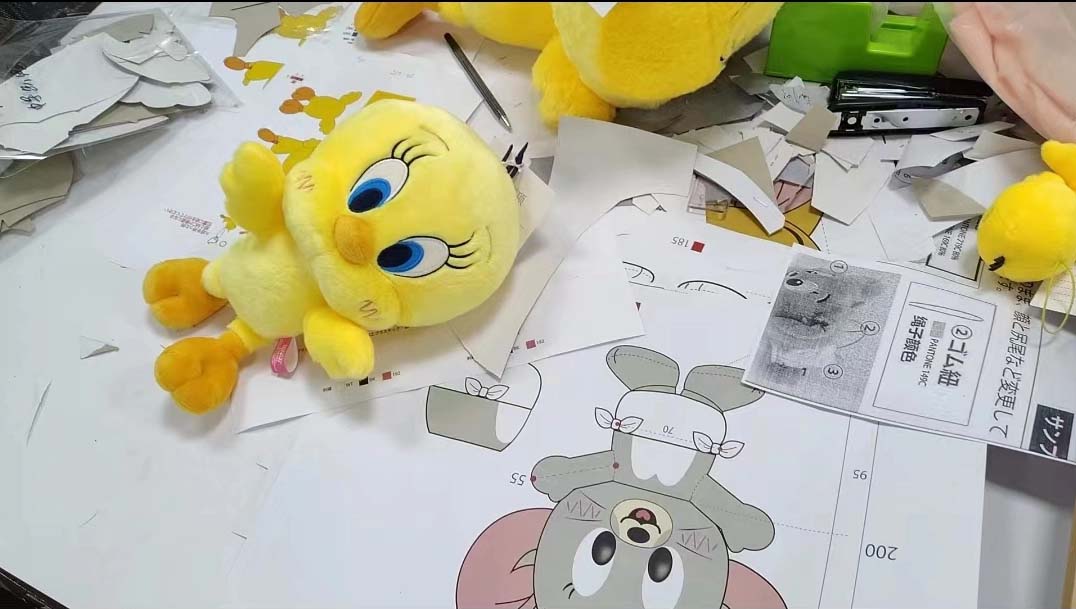

If design files explain what a plush toy should look like, pattern making decides how that idea becomes a physical object. From my experience, pattern making is the most decisive step in achieving sample accuracy, yet it is also the least understood by many buyers.

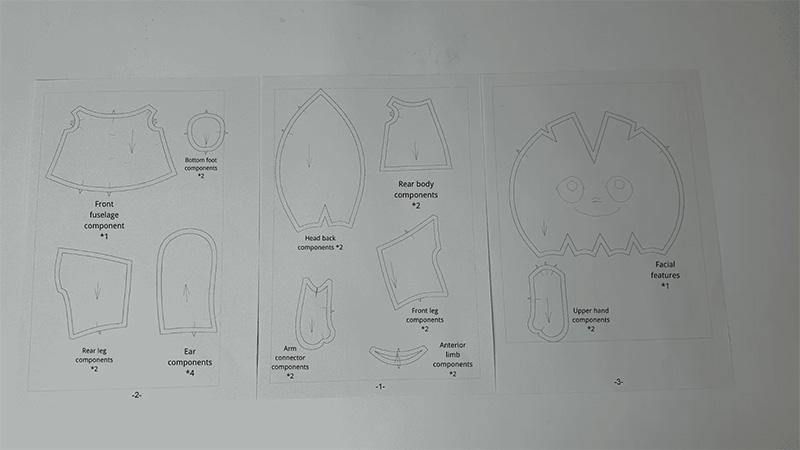

Pattern making is not copying a drawing. It is the process of translating flat artwork into multiple fabric pieces that must work together once stitched and stuffed.

Key ways pattern making affects sample accuracy include:

- Conversion from flat shapes to three-dimensional volume A 2D design shows outlines, but a plush toy needs depth. Pattern makers must calculate how much fabric is required to create roundness in the head, body, and limbs. This directly affects fullness and proportion.

- Distribution of seams and panels Where seams are placed determines how curves form. Seams around cheeks, foreheads, or bellies subtly reshape outlines compared to drawn lines.

- Balance between appearance and structure Very thin arms, legs, or ears may look accurate in drawings but collapse in real life. Pattern makers often adjust thickness to ensure durability and long-term shape retention.

- Compensation for fabric stretch and stuffing pressure Plush fabrics stretch differently, and stuffing pushes fabric outward. Pattern makers adjust panel size and angles to control how the plush settles after filling.

- Symmetry control in soft materials Perfect symmetry is harder to achieve in plush than in hard toys. Good pattern making reduces visual imbalance by anticipating fabric behavior.

Typical buyer comments during sample review—and what they usually mean:

- “The head feels rounder than expected” Extra volume was added to support structure and softness.

- “The arms look thicker than in the drawing” Thickness was increased to prevent seam stress and deformation.

- “The proportions feel slightly different” Adjustments were made to make the plush look correct in 3D, not just in illustration.

| Pattern Making Factor | Why It Matters | Impact on Sample Accuracy |

|---|---|---|

| Volume allowance | Creates 3D form | Controls fullness |

| Seam placement | Shapes curves | Alters outlines |

| Thickness adjustment | Improves durability | Changes proportions |

| Stretch compensation | Manages fabric behavior | Prevents distortion |

| Symmetry planning | Balances appearance | Improves visual accuracy |

For brands, understanding pattern making helps shift expectations from “match the drawing exactly” to “make the plush look right in real life.”

At Kinwin, our pattern makers explain these adjustments during sampling so clients understand why certain changes improve both accuracy and product quality.

What Role Do Fabric Selection and Material Substitution Play in Accuracy?

Even with accurate patterns, the wrong fabric—or an unplanned material substitution—can quickly reduce sample accuracy. From my experience, many “accuracy issues” are actually material behavior issues that were not discussed early enough.

Plush fabrics behave differently once they are cut, sewn, and stuffed. Understanding this behavior is critical to keeping samples aligned with design intent.

Key ways fabric choice affects sample accuracy include:

- Pile length changes perceived size and shape Long-pile fabrics add visual volume and soften edges, making heads look larger and limbs shorter. Short-pile fabrics keep outlines closer to the design.

- Fabric density affects detail clarity Dense fabrics hold embroidery, eye placement, and seams more clearly. Loose or fluffy fabrics can blur facial details.

- Stretch and recovery influence proportions Some fabrics stretch during sewing and do not fully recover after stuffing, leading to wider bodies or uneven symmetry.

- Surface reflection alters color appearance The same color can look different depending on fabric sheen and pile direction, which may cause perceived “color mismatch” with the design.

Material substitution during sampling is another common factor:

- Sample fabrics may differ from production fabrics When exact fabrics are not available for sampling, substitutes may be used. These can change hand feel, thickness, and visual weight.

- Small material changes create noticeable differences Even slight differences in pile height or backing thickness can affect how accurate a sample feels.

- Substitution without explanation creates confusion If buyers are not informed clearly, they may judge accuracy based on materials that will not be used in final production.

Common buyer reactions—and what they usually indicate:

- “The sample looks bigger than expected” Likely caused by fluffy or thicker fabric.

- “The face details are not sharp” Often due to fabric pile covering embroidery.

- “The color feels off” Frequently caused by fabric reflection, not dye error.

| Material Factor | What Changes | Impact on Accuracy |

|---|---|---|

| Pile length | Visual volume | Alters proportions |

| Fabric density | Detail visibility | Affects facial clarity |

| Stretch | Final dimensions | Causes distortion |

| Surface shine | Color perception | Appears lighter/darker |

| Substitution | Hand feel & shape | Misaligned expectations |

For brands, the key to accuracy is aligning fabric decisions before sampling starts. At Kinwin, we always confirm whether sample fabrics match production fabrics and clearly explain any substitutions, so buyers evaluate accuracy based on the right reference.

How Can Structured Sample Reviews and Revisions Improve Accuracy?

Sample accuracy rarely comes from a single round. In professional plush development, accuracy is achieved through controlled review cycles, not repeated trial-and-error. From my experience, the difference between frustrating sampling and efficient sampling is whether feedback is structured.

Unstructured feedback often sounds like:

“It doesn’t feel right.”

“The face looks off.”

“This isn’t what we imagined.”

These comments express emotion, but they do not help pattern makers correct the problem.

Structured sample reviews focus on specific, actionable points.

Effective sample review usually includes:

- Reviewing one category at a time Separate feedback into shape, proportion, material, facial details, and construction. Mixing everything together slows revisions.

- Comparing against agreed references Accuracy should be judged against approved drawings, reference plush, or written priorities—not memory or assumptions.

- Identifying root causes, not symptoms Instead of “the head is too big,” note whether the issue is fabric thickness, pattern volume, or stuffing level.

- Distinguishing must-change vs acceptable differences Not every difference requires revision. Clear priorities help factories focus on what truly affects brand identity.

- Using visual markup Marked photos with arrows, notes, or simple measurements reduce misunderstanding across language barriers.

- Limiting revision scope per round Too many changes at once increase risk. Focused revisions lead to faster convergence.

Common reasons revisions fail to improve accuracy:

- Feedback is vague or emotional

- Changes are requested without understanding production impact

- Priorities change between revision rounds

- Too many adjustments are requested simultaneously

| Review Practice | Unstructured Approach | Structured Approach |

|---|---|---|

| Feedback style | General comments | Specific points |

| Reference use | Memory-based | File-based |

| Problem analysis | Visual reaction | Root-cause focus |

| Priority setting | Everything urgent | Clear must-fix |

| Communication | Text only | Marked images |

| Revision speed | Slow & repetitive | Faster convergence |

For brands, structured reviews turn sampling into a predictable improvement process instead of repeated disappointment. At Kinwin, we guide clients through sample reviews step by step, helping translate feedback into technical adjustments that actually improve accuracy.

How Do Factories Maintain Consistency from Approved Samples to Production?

For many brands, the biggest fear is not whether a sample looks good—but whether mass production will still look the same. Sample accuracy only has real value if it can be repeated consistently at scale.

In professional plush manufacturing, consistency is not left to chance. It is protected by systems, documents, and control points that lock the approved sample into production.

Key ways factories maintain consistency include:

- Golden sample confirmation Once a sample is approved, it becomes the physical reference for production. All departments align to this sample, not to memory or photos alone.

- Detailed production specifications Measurements, fabric codes, embroidery files, stuffing weight, seam positions, and tolerance ranges are documented and shared across teams.

- Material locking before production Fabrics, fillings, threads, and accessories are confirmed and reserved. Unauthorized substitutions are avoided unless approved by the buyer.

- Pre-production samples (PPS) A PPS is made using real production materials and processes. It confirms that accuracy is achievable under mass-production conditions.

- In-line quality control checkpoints During sewing and stuffing, inspectors compare work against the golden sample to catch deviations early, not at the end.

- Final inspection based on approved standards Finished products are checked against agreed tolerances, not personal judgment.

Common risks when factories lack consistency controls:

- Approved samples are not referenced during production

- Different teams interpret designs differently

- Materials are changed due to stock issues without notice

- Quality checks happen too late to correct problems

| Consistency Tool | Purpose | Risk Reduced |

|---|---|---|

| Golden sample | Visual benchmark | Design drift |

| Spec sheets | Technical alignment | Misinterpretation |

| Material lock | Input stability | Appearance change |

| PPS | Production validation | Scale mismatch |

| In-line QC | Early correction | Mass defects |

| Final inspection | Shipment control | Buyer complaints |

For brands, choosing a factory with strong consistency systems is just as important as sample quality itself. At Kinwin, we treat approved samples as production contracts, not suggestions—so what you approve is what you receive.

Conclusion

Ensuring plush toy sample accuracy is not about perfection in one round. It is about clear expectations, strong technical translation, structured reviews, and production discipline. When brands and factories work within a clear system, sample accuracy becomes repeatable, reliable, and scalable—turning ideas into products you can confidently launch.

If you want support improving sample accuracy and maintaining consistency into mass production, our team at Kinwin is always ready to help.

Contact: [email protected]

Visit: https://kinwintoys.com