Designing a stuffed animal for more than one market is very different from designing for a single region. From my experience working with global buyers, the biggest challenge is not creativity—it is how to keep a design flexible without losing control over cost, safety, and production consistency.

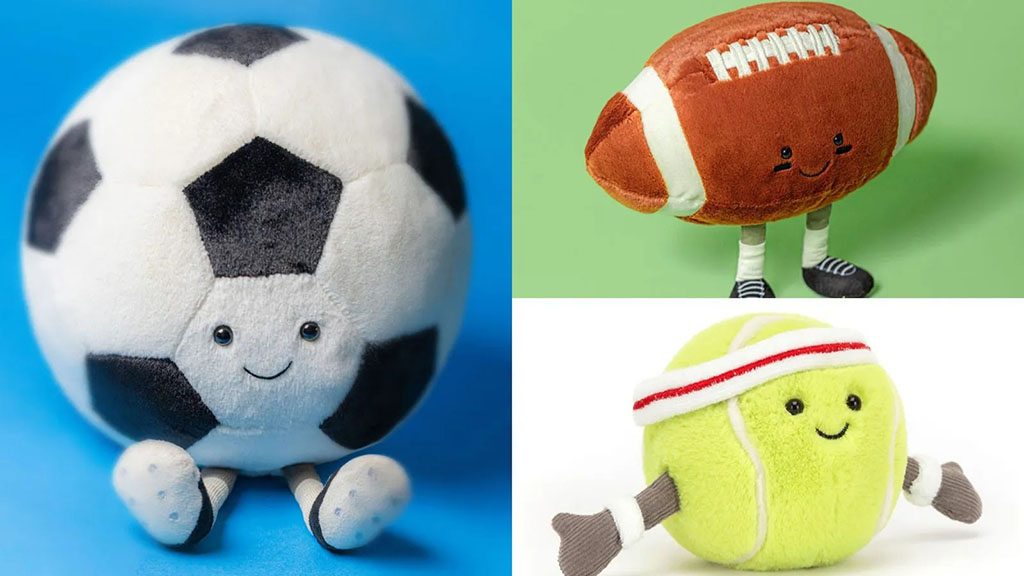

Different markets have different expectations for size, color, safety, and even emotional expression. A design that performs well in North America may need adjustments for Europe, Japan, or the Middle East. If flexibility is not built into the design from the beginning, every market request can turn into a full redesign, increasing time and risk.

Before thinking about materials or compliance, the first step is to identify which core design elements must remain flexible so the same stuffed animal concept can be adapted efficiently across multiple regional markets.

What Core Design Elements Must Stay Flexible for Different Regional Markets?

When designing a stuffed animal for multiple markets, not every element needs to change—but certain elements must be intentionally flexible. From my experience, successful multi-market designs clearly separate fixed structural elements from adjustable design elements.

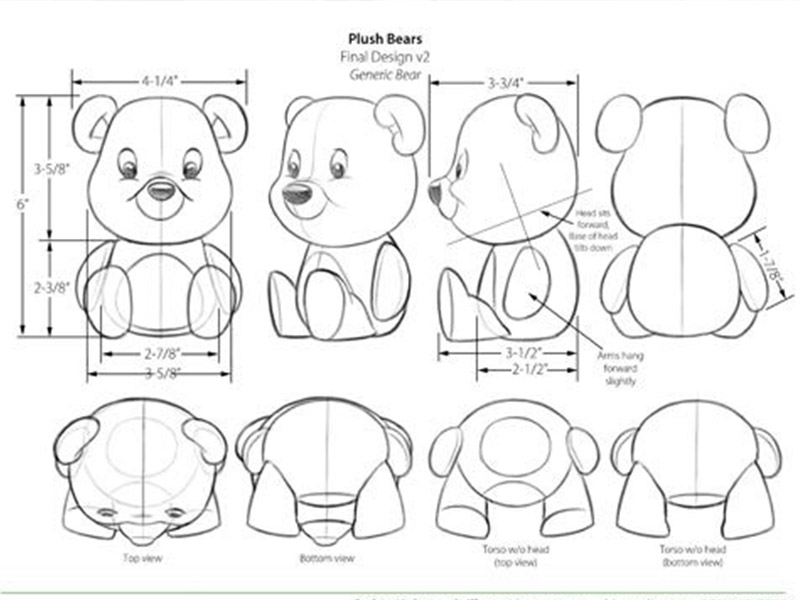

The core structure of the toy—its basic shape, internal construction, and sewing logic—should remain stable. This ensures production efficiency and quality consistency. However, visual and sensory elements often need flexibility to meet regional preferences.

Facial expression is one of the most important flexible elements. Small changes in eye shape, embroidery style, or mouth placement can significantly affect how a toy is perceived in different cultures. Professional designs allow these features to be adjusted without altering the underlying pattern structure.

Color is another key variable. Markets respond differently to color saturation, contrast, and palette choices. A flexible design anticipates color swaps and defines approved color ranges that can be adapted per market without reworking materials or patterns.

Accessories and decorative details should also be modular. Items such as clothing, hats, tags, or small props can be added, removed, or localized while keeping the base toy unchanged. This allows brands to customize for seasons, regions, or promotions with minimal disruption.

The goal is not unlimited flexibility, but controlled flexibility—designing elements that can change independently without affecting the rest of the product.

| Design Element | Fixed or Flexible | Why It Matters for Multi-Market Design | Buyer Benefit |

|---|---|---|---|

| Core body structure | Fixed | Maintains production stability | Cost & quality control |

| Facial expression | Flexible | Cultural preference adaptation | Market acceptance |

| Color palette | Flexible | Regional taste differences | Faster localization |

| Accessories | Flexible | Seasonal or regional variation | Customization efficiency |

| Labels & tags | Flexible | Language & regulation needs | Compliance readiness |

For buyers targeting multiple markets, flexibility at the design stage reduces future cost and complexity. Factories that understand how to separate fixed and adjustable elements help brands scale designs globally without constant redevelopment.

How Can Modular Design Support Easy Customization Without Redesigning the Whole Toy?

When a stuffed animal needs to serve multiple markets, modular design becomes one of the most effective tools for controlling cost and speed. From my experience, many customization projects fail not because the idea is complex, but because the original design was never built to be modified.

Modular design means breaking the toy into functional sections that can be changed independently. Instead of redesigning the entire product for each market, brands can adjust specific modules—such as facial elements, accessories, or surface decorations—while keeping the core structure unchanged. This approach reduces development time and minimizes production risk.

One common modular area is the head and face zone. By keeping the head shape stable and treating eyes, mouths, and expressions as separate embroidery or appliqué modules, factories can adjust the toy’s personality without altering patterns or sewing flow. This is especially useful when adapting to cultural preferences.

Accessories are another strong modular element. Clothing, hats, scarves, or small props can be designed as add-ons rather than permanent parts of the toy. This allows easy removal or replacement based on market, season, or promotion—without changing the base product.

Color and material modules also support customization. When fabrics and trims are selected from pre-approved material sets, color swaps become manageable. The key is defining limits early so customization stays within a controlled range.

Modular design works best when it is planned at the pattern stage, not added later. Factories experienced in OEM production understand how to design connection points, sewing allowances, and tolerances to support future variation.

| Modular Area | Modular Design Approach | Customization Benefit | Production Impact |

|---|---|---|---|

| Core body | Fixed structure | Stable base for all markets | Cost control |

| Facial features | Separate embroidery modules | Cultural adaptation | Minimal rework |

| Accessories | Detachable add-ons | Seasonal & regional variation | Flexible assembly |

| Color sets | Pre-approved palettes | Fast localization | Material efficiency |

| Decorative elements | Appliqué or patch modules | Brand differentiation | Controlled complexity |

For buyers, modular design is not about endless options. It is about smart limitations that allow customization without chaos. Factories that design with modularity in mind help brands move faster across markets while keeping production predictable and scalable.

How Do Size, Color, and Feature Variations Adapt to Market-Specific Preferences?

When a customizable stuffed animal enters multiple markets, size, color, and feature variations become the most visible points of localization. From my experience, these variations must be handled carefully—too much change increases cost and complexity, while too little change limits market acceptance.

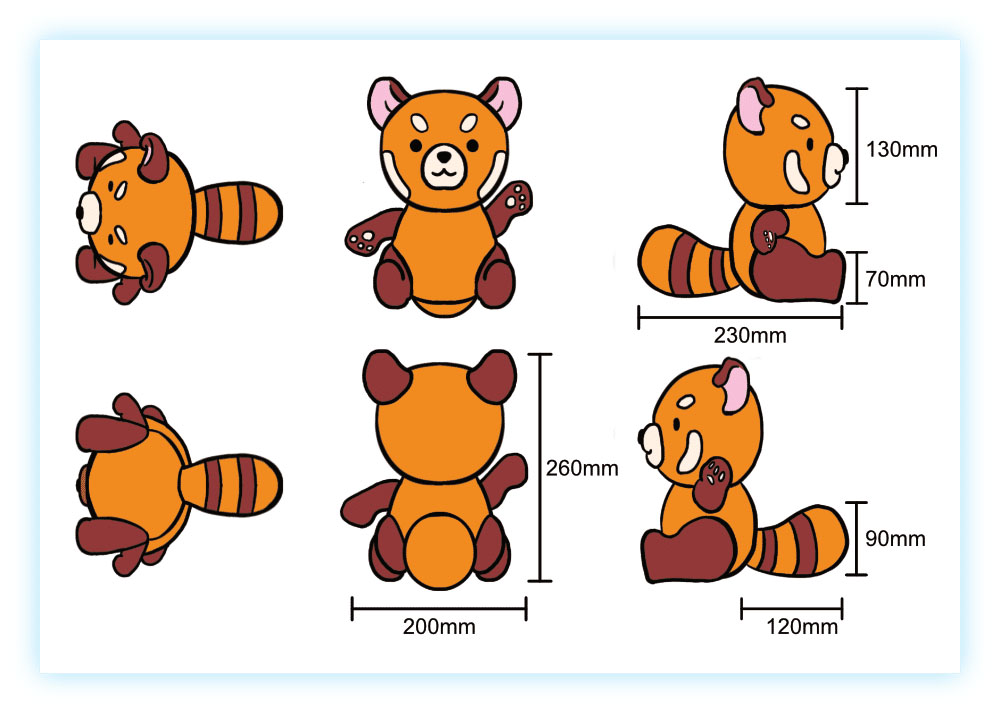

Size variation is often driven by retail context and consumer behavior. In North America and Europe, mid-to-large sizes are commonly used for gifting and display. In Japan and parts of Asia, compact sizes are preferred for portability and collection. Professional designs plan size grading in advance, using the same pattern logic scaled proportionally rather than creating new patterns for each size.

Color variation is another critical factor. Some markets prefer bright, high-contrast colors, while others respond better to softer, muted tones. Instead of offering unlimited color options, professional factories define approved color families that align with brand identity and compliance requirements. This keeps customization controlled while still allowing regional adaptation.

Feature variation includes elements such as facial expression, ear shape, tail length, or accessory presence. These features influence how “cute,” “friendly,” or “premium” a toy feels in different cultures. Successful multi-market designs limit feature changes to surface-level adjustments that do not affect internal construction or safety testing.

The goal is to design variation paths that are predictable. When size, color, and features are planned as options rather than exceptions, customization becomes scalable instead of disruptive.

| Variation Type | Controlled Adjustment Method | Regional Driver | Production Advantage |

|---|---|---|---|

| Size | Proportional pattern grading | Retail format & usage | Shared pattern logic |

| Color | Approved color families | Cultural preference | Material efficiency |

| Facial details | Embroidery style swaps | Emotional perception | No structural change |

| Accessories | Optional add-ons | Market positioning | Flexible assembly |

| Surface features | Limited shape variations | Design taste | Safety stability |

For buyers, well-managed variation is a sign of mature design thinking. Factories that plan size, color, and feature options early help brands adapt to different markets without repeated redesigns, delays, or unexpected costs.

What Safety Standards and Compliance Requirements Must Be Considered Across Markets?

When designing a customizable stuffed animal for multiple markets, safety and compliance are not optional layers added at the end—they must be embedded into the design from the very beginning. From my experience, many multi-market projects fail or become costly because safety requirements were treated as market-specific fixes instead of global design constraints.

Different regions apply different regulatory frameworks. For example, the United States focuses on ASTM F963 and CPSIA, while the European Union requires EN71 and CE conformity. Japan, South Korea, and Middle Eastern markets each have their own testing scopes and documentation expectations. A design that ignores these differences early will face repeated re-testing, redesign, or even market exclusion.

The most effective approach is to design to the highest common safety denominator. This means selecting materials, components, and construction methods that can pass the strictest applicable standards across target markets. When this baseline is set, adapting to individual market documentation becomes much easier.

Small parts and attachments require special attention. Eyes, noses, accessories, and decorative elements must be secured using methods that meet pull-force and torque requirements across regions. Similarly, seam strength, stuffing containment, and fabric durability must be consistent regardless of size or feature variation.

Labeling and documentation are also part of compliance design. Space for tracking labels, care instructions, and market-specific warnings should be planned into the product layout rather than added later as stickers or tags.

| Compliance Area | Multi-Market Design Approach | Why It Matters | Buyer Benefit |

|---|---|---|---|

| Safety standards | Design to strictest market | Avoids redesign | Faster approvals |

| Materials | Certified & traceable | Chemical compliance | Lower recall risk |

| Small parts | Secure attachment methods | Child safety | Market access |

| Construction | Reinforced seams & enclosures | Durability & safety | Fewer failures |

| Labeling | Planned label placement | Regulatory clarity | Smooth customs clearance |

For buyers, compliance-ready design reduces both cost and stress. Factories that understand cross-market safety requirements help brands launch products globally without constant redesign or unexpected certification delays.

How Should Materials and Construction Be Selected to Meet Diverse Market Expectations?

When a stuffed animal is designed for multiple markets, material and construction choices must balance global consistency with local expectations. From my experience, many multi-market designs fail not because materials are poor, but because they are selected without a clear strategy for how different regions perceive quality, value, and safety.

Different markets associate quality with different signals. Some prioritize softness and touch, others focus on durability and structure, while certain regions are more sensitive to eco-friendly or certified materials. Professional multi-market designs start by defining a shared material baseline that meets safety, durability, and compliance needs across all regions.

Fabric selection should prioritize stability first, then feel. A fabric that performs well in one market but sheds, fades, or stretches in another creates inconsistency and increases returns. Reliable factories favor fabrics with proven performance across climates, washing conditions, and handling frequency.

Construction methods also need to be standardized. Stitch density, seam allowance, reinforcement points, and stuffing containment should remain consistent across all market versions. This ensures that size or feature changes do not introduce hidden weaknesses or safety risks.

At the same time, limited material variation can be used strategically. For example, premium lines may use denser plush or higher-grade filling, while value-oriented markets use the same construction with adjusted surface materials. The key is that construction logic stays the same, even when material grades differ.

| Material & Construction Area | Multi-Market Strategy | Regional Adaptation | Production Advantage |

|---|---|---|---|

| Core fabric | Proven, stable plush base | Texture grade variation | Consistent performance |

| Filling | Standardized density ranges | Softness adjustment | Shape control |

| Stitching | Fixed stitch specs | None | Structural safety |

| Reinforcement | Defined stress-point rules | None | Durability |

| Material upgrades | Tiered material options | Market positioning | Cost flexibility |

For buyers, material and construction discipline reduces surprises. Factories that define clear baselines and controlled variation help brands meet diverse market expectations without sacrificing safety, consistency, or production efficiency.

How Can Early Market Feedback and OEM Collaboration Optimize Multi-Market Designs?

Designing a customizable stuffed animal for multiple markets should never be a one-direction process. From my experience, the most successful multi-market products are optimized through early feedback loops and close OEM collaboration, long before mass production begins.

Early market feedback helps validate assumptions. Pilot samples, small test runs, or pre-launch reviews with distributors and retailers often reveal insights that design teams cannot predict alone. Feedback may relate to size preference, facial expression, color tone, or perceived value. Capturing these signals early prevents costly redesigns later.

OEM collaboration is critical in translating feedback into actionable design adjustments. Experienced OEM partners understand how to modify patterns, materials, or accessories without disrupting the overall structure. They can quickly assess whether a requested change affects tooling, compliance, or lead time—and propose alternatives when risks appear.

Sampling strategy plays a key role here. Iterative sampling, with clear comparison points and documented changes, allows buyers to test variations efficiently. Professional OEMs maintain version control, ensuring feedback is reflected accurately and consistently across samples.

Another advantage of close collaboration is design for manufacturability. OEM partners can suggest simplifications, modular tweaks, or material substitutions that maintain market appeal while improving production stability and cost control across regions.

The goal is not endless iteration, but informed convergence—using real feedback and OEM expertise to lock a design that works reliably across markets.

| Optimization Stage | OEM Collaboration Focus | Value of Early Feedback | Buyer Benefit |

|---|---|---|---|

| Concept validation | Feasibility & risk review | Avoids wrong assumptions | Faster alignment |

| Sample iteration | Controlled design adjustments | Tests market response | Reduced redesign cost |

| Feedback analysis | Pattern & material tuning | Improves acceptance | Higher sell-through |

| Manufacturability | Process optimization | Prevents production issues | Stable scaling |

| Design lock | Final spec confirmation | Cross-market readiness | Confident launch |

For buyers, early feedback combined with strong OEM collaboration transforms customization from a risk into a competitive advantage. Factories that support this process help brands launch adaptable designs globally—faster, safer, and with greater confidence.

Conclusion

Designing a customizable stuffed animal for multiple markets requires controlled flexibility, modular thinking, and early collaboration. When design, compliance, materials, and OEM expertise align from the start, brands can scale globally with confidence in quality, safety, and efficiency.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com