From my experience, most risks in plush manufacturing are not created during mass production—they are locked in much earlier, at the prototype stage. A rushed or unclear prototype approval often leads to quality drift, cost surprises, and production delays later on.

Developing and approving a custom plush prototype is not just about making a sample that “looks good.” It is about verifying that the design can be produced consistently, safely, and at scale. When this step is handled with structure, mass production becomes far more predictable.

Everything starts with preparation. Before any prototype is made, buyers and factories must align on what information is required and how design intent will be translated into something manufacturable.

What Design Files, References, and Specifications Are Required Before Prototyping Starts?

Successful plush prototyping begins with clear and complete inputs. From my experience, most prototype delays and misunderstandings happen because factories are forced to guess due to missing or vague information.

The most important input is a primary design reference. This can be a drawing, a 3D file, or reference pictures, but buyers should clearly state which file represents the final intent. Multiple unranked references often create confusion rather than clarity.

Basic specifications must be defined early. These include target size, expected softness, fabric type, filling preference, and intended use (toy, gift, promotional item). Even approximate ranges help factories make better decisions during pattern making.

Color references should be practical. Pantone codes, fabric swatches, or physical references work better than screen-only colors, which vary by display. Clear color direction reduces unnecessary revision rounds.

Functional and safety requirements also matter at this stage. If the plush must sit, stand, include accessories, or meet specific safety standards, these conditions should be stated before prototyping—not after the first sample is made.

Finally, buyers should communicate what matters most. Identifying priority features helps factories focus effort where accuracy is critical, while allowing flexibility elsewhere.

| Input Category | Incomplete Input | Well-Prepared Input | Prototyping Impact |

|---|---|---|---|

| Design reference | Multiple unclear files | One primary reference | Clear direction |

| Size & feel | “Standard size” | Target size & softness | Correct proportions |

| Color guidance | Screen images only | Pantone or swatches | Fewer revisions |

| Functional needs | Mentioned later | Defined upfront | Structural accuracy |

| Safety requirements | Assumed | Stated clearly | Compliance-ready |

| Priority features | Not defined | Clearly highlighted | Focused accuracy |

For buyers, strong preparation turns prototyping into a controlled development process rather than trial-and-error. When inputs are clear from the start, factories can translate design intent into a prototype that is both accurate and production-ready.

How Do Factories Conduct Feasibility Reviews to Avoid Prototype-to-Production Gaps?

Before a plush prototype is made, professional factories carry out a feasibility review to ensure the design can move smoothly from sample to mass production. From my experience, this step is what separates prototypes that “look good once” from products that can be produced consistently at scale.

The review starts with design intent analysis. Factories examine the shape, proportions, and features to identify areas that may be difficult to replicate—such as sharp angles, ultra-thin limbs, or overly complex facial details. These elements are flagged early so adjustments can be discussed before sampling.

Next comes material feasibility. Not all fabrics behave the same during cutting, sewing, and stuffing. Factories evaluate whether the chosen materials can hold the intended shape, maintain color consistency, and meet durability and safety requirements under mass production conditions.

Process feasibility is equally important. Factories assess whether the design requires special machinery, manual operations, or unusually high skill levels. If a process is too slow or unstable for volume production, alternatives are proposed early to avoid bottlenecks later.

Cost and yield are also reviewed. Designers and engineers estimate material usage, labor time, and expected defect risk. Designs that look simple but generate high waste or rework rates are adjusted to protect cost stability.

Finally, compliance risk is checked. If the plush is intended for regulated markets, factories confirm whether the structure, attachments, and materials can realistically pass required safety tests without redesign.

| Review Area | Risk If Ignored | Feasibility Review Action | Production Benefit |

|---|---|---|---|

| Design complexity | Sample-only success | Structural simplification | Scalable design |

| Material behavior | Shape loss | Fabric suitability check | Stable appearance |

| Process demands | Low efficiency | Process optimization | Predictable output |

| Cost & yield | Hidden overruns | Early cost modeling | Budget control |

| Compliance readiness | Test failure | Safety risk assessment | Fewer delays |

For buyers, feasibility reviews are a risk filter, not an obstacle. When factories challenge designs early and transparently, the final prototype is far more likely to transition smoothly into mass production without costly surprises.

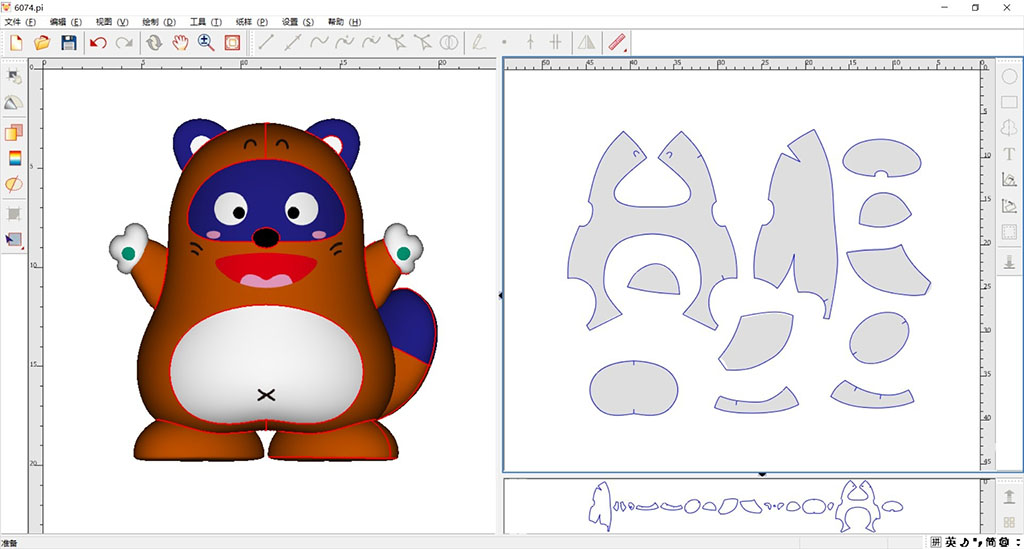

How Does Pattern Making and First Sample Development Translate Design into Structure?

Pattern making and first sample development are where a plush design stops being an idea and becomes a physical system. From my experience, this stage determines whether the prototype can later be reproduced with consistency, not just whether it looks acceptable once.

Pattern makers begin by breaking the design into functional components—head panels, body segments, limbs, ears, tails, and any accessories. Each piece is shaped to control volume, curvature, and balance. When working from drawings or pictures, experienced pattern makers make calculated assumptions and document them for review.

Seam placement is a critical decision. Seams define the final silhouette and influence how fabric stretches and compresses when stuffed. Poor seam logic often causes asymmetry, distorted expressions, or instability during mass production. Professional teams design seams to balance appearance, strength, and sewing efficiency.

The first sample then validates these structural decisions. It tests whether proportions feel right in hand, whether the plush holds its shape, and whether features align naturally. This sample is not judged only on appearance—it is evaluated for repeatability.

Material behavior is closely observed at this stage. Fabrics may stretch differently than expected, embroidery may pull panels out of shape, or stuffing density may affect posture. These findings are fed back into pattern adjustments before further samples are made.

Importantly, the first sample also reveals process constraints. If a design requires excessive manual correction or highly skilled sewing to look acceptable, it is refined. The goal is a structure that looks good and can be produced consistently by different operators.

| Development Focus | Weak Execution | Professional Execution | Production Outcome |

|---|---|---|---|

| Pattern logic | Visual approximation | Structure-driven pattern | Stable form |

| Seam placement | Convenience-based | Shape & strength balanced | Clean silhouette |

| First sample role | Appearance check | Structural validation | Scalable design |

| Material response | Ignored | Tested and adjusted | Consistent feel |

| Repeatability | Not evaluated | Core requirement | Mass-ready prototype |

For buyers, understanding this stage explains why pattern making and first samples cannot be rushed. This is where design intent is translated into a manufacturable structure—and where most long-term production risks are either eliminated or locked in.

What Key Details Should Be Evaluated When Reviewing a Plush Prototype?

Reviewing a plush prototype is not a visual approval exercise—it is a risk evaluation step. From my experience, buyers who review prototypes with a structured checklist prevent most mass-production issues before they happen.

The first focus is overall proportions and balance. Hold the prototype, place it on a flat surface, and view it from multiple angles. Check head-to-body ratio, limb thickness, and posture. A plush that looks acceptable in photos may feel unstable or awkward in hand.

Next, evaluate facial features and expression accuracy. Eyes, nose, mouth, and ear placement define character identity. Confirm spacing, symmetry, and emotional direction match the intent. Small deviations here often amplify during production.

Material performance is another critical area. Touch the fabric, squeeze the body, and observe rebound. Check whether the chosen fabric and filling deliver the intended softness, resilience, and surface appearance without distortion.

Workmanship details should be reviewed closely. Inspect seam alignment, stitch density, embroidery edges, and closure points. These details indicate how well the design will hold up under repeated handling and washing.

Functionality and safety must be confirmed early. If the plush needs to sit, stand, or include attachments, test these functions now. Look for loose parts, sharp edges, or stress points that could fail safety tests later.

Finally, think in terms of repeatability. Ask whether this prototype can be produced the same way by different operators. If it relies on exceptional craftsmanship to look good, it may need simplification before approval.

| Review Area | Common Oversight | Professional Evaluation | Risk Reduction |

|---|---|---|---|

| Proportions & balance | Photo-only review | In-hand & multi-angle | Structural stability |

| Facial features | “Looks fine” | Measured placement check | Identity accuracy |

| Material behavior | Visual only | Touch & compression test | Consistent feel |

| Workmanship | Surface glance | Detail inspection | Durability |

| Function & safety | Assumed | Physical testing | Compliance readiness |

| Repeatability | Ignored | Production realism check | Scalable quality |

For buyers, a disciplined prototype review turns approval into a decision point, not a formality. When key details are evaluated methodically, the approved prototype becomes a reliable foundation for mass production.

How Do Revision Rounds and Feedback Loops Lead to an Approved Golden Sample?

Revision rounds are not a sign of failure—they are the mechanism that turns a good prototype into a production-ready golden sample. From my experience, the quality of revisions matters more than the number of revisions.

The first principle is focused revisions. Each round should address a limited set of issues—such as proportions, facial expression, or material behavior—rather than changing everything at once. This prevents instability and makes results measurable.

Clear, prioritized feedback is essential. Buyers should specify what must change, what should stay the same, and what is acceptable within tolerance. Vague comments like “make it better” slow progress and increase misinterpretation.

Visual guidance accelerates accuracy. Annotated photos, comparison images, and short notes reduce language barriers and help pattern makers adjust with precision. This is especially important when refining facial features or seam placement.

Confirmation closes the loop. After revisions, factories should summarize changes made and ask for confirmation. This ensures both sides agree before moving to the next step and prevents old issues from reappearing.

Once all critical points are resolved, the golden sample is locked. This sample becomes the single physical reference for materials, workmanship, and structure. Version control is crucial—any later changes require formal approval and a new reference.

| Revision Control Area | Weak Practice | Professional Practice | Approval Outcome |

|---|---|---|---|

| Revision scope | Many changes at once | Focused adjustments | Stable progress |

| Feedback clarity | General comments | Prioritized instructions | Faster convergence |

| Communication tools | Text-only | Visual annotations | Precise execution |

| Change confirmation | Assumed | Written summaries | No backtracking |

| Golden sample control | Informal | Version-locked reference | Production alignment |

For buyers, disciplined revision rounds transform iteration into certainty. When feedback is clear and changes are confirmed, the approved golden sample becomes a dependable bridge between prototyping and mass production.

How Does Prototype Approval Reduce Risk and Ensure Smooth Mass Production?

Prototype approval is the point where uncertainty is either eliminated or carried forward. From my experience, when a plush prototype is approved with clear standards and documentation, most mass-production risks are already controlled before the first bulk unit is made.

First, an approved prototype locks technical decisions. Materials, patterns, seam logic, stuffing density, and workmanship expectations are no longer debated during production. This stability allows production teams to focus on execution rather than interpretation.

Second, approval enables accurate production planning. With a frozen design, factories can calculate material yield, labor time, and line capacity reliably. This reduces schedule changes, cost surprises, and last-minute compromises.

Third, the approved prototype becomes the training reference. Operators, line leaders, and inspectors all align to the same physical standard. This minimizes variation across shifts and lines—one of the biggest risks in early mass production.

Fourth, quality control becomes objective. Golden samples derived from the approved prototype allow IPQC, AQL inspections, and third-party checks to measure against a fixed benchmark. Disputes are reduced because acceptance criteria are visible and shared.

Finally, approval strengthens accountability. When changes are needed after approval, they are treated as controlled revisions, not informal adjustments. This discipline protects timelines and prevents scope creep.

| Risk Area | Before Approval | After Approval | Production Impact |

|---|---|---|---|

| Design interpretation | Variable | Locked | Consistent output |

| Cost & scheduling | Estimated | Planned | Predictable delivery |

| Operator alignment | Verbal | Sample-based | Lower variation |

| Quality decisions | Subjective | Objective reference | Fewer disputes |

| Change control | Informal | Approved revisions | Stable execution |

For buyers, prototype approval is not a checkpoint—it is a risk transfer moment. When done correctly, it shifts uncertainty out of mass production and into a controlled, repeatable system.

Conclusion

A well-managed plush prototype process transforms ideas into production-ready standards. When inputs, feasibility, sampling, review, and approval are structured, mass production becomes predictable, scalable, and low-risk.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com