Choosing the right cuddly toy manufacturer is a critical decision for retail brands. Unlike one-off promotional plush, retail cuddly toys must perform consistently across safety, appearance, supply stability, and consumer experience. From first sample to repeated seasonal replenishment, the manufacturer you select directly impacts product quality, shelf performance, and long-term brand trust. Below are the key factors retail buyers should evaluate before committing to a cuddly toy manufacturing partner.

What Manufacturing Experience and Product Focus Matter Most for Retail Success?

Retail-focused cuddly toy production requires a different mindset than gift, promotional, or one-time OEM plush. A qualified manufacturer should demonstrate long-term experience specifically in retail plush categories, including animals, comfort toys, and character-adjacent designs. This experience shows that the factory understands shelf presentation, consumer handling, and repeat purchase expectations.

Product focus matters as much as years in business. Manufacturers that consistently produce cuddly toys for retail usually have standardized processes for softness control, shape consistency, and color stability. They also understand how small design changes can affect consumer perception and return rates. Factories without this focus may struggle to maintain consistency across large retail orders.

| Evaluation Area | What to Look For | Retail Benefit | Buyer Tip |

|---|---|---|---|

| Industry experience | 5–10+ years in plush | Process maturity | Ask for retail case studies |

| Product focus | Cuddly / comfort toys | Market fit | Avoid overly mixed factories |

| Past clients | Retail brands | Proven scalability | Request references |

| SKU continuity | Repeat models | Stable supply | Check re-order history |

How Do Design Support and Sampling Capabilities Affect Cuddly Toy Appeal?

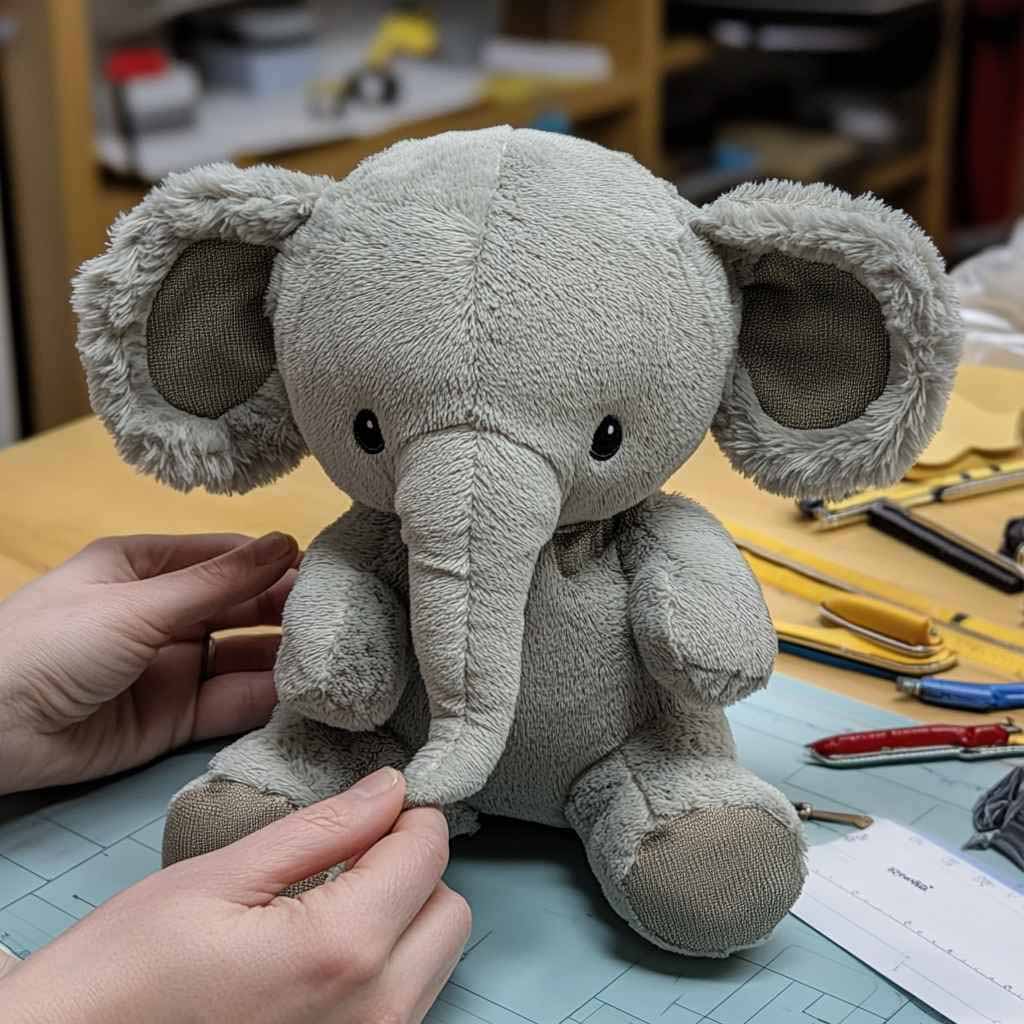

Design support and sampling quality directly determine whether a cuddly toy feels emotionally appealing on shelf. Retail plush must look inviting, feel soft at first touch, and maintain proportions that encourage hugging. A capable manufacturer should offer pattern making, material suggestions, and structural adjustments—not just copy provided artwork.

Sampling speed is equally important. Retail timelines are often tight, especially for seasonal collections. Manufacturers with in-house sample rooms and experienced pattern makers can deliver accurate prototypes quickly, allowing brands to test, revise, and approve designs without delay. Poor sampling leads to repeated revisions, missed seasons, and higher development costs.

| Capability | Strong Manufacturer | Retail Impact | Buyer Action |

|---|---|---|---|

| Pattern making | In-house team | Accurate proportions | Review sample room |

| Material advice | Proactive suggestions | Better hand-feel | Ask for alternatives |

| Sampling speed | 7–15 days | Faster go-to-market | Confirm timelines |

| Revision handling | Structured feedback | Fewer delays | Test revision rounds |

What Quality Control Systems Ensure Consistent Retail-Ready Products?

Retail buyers rely on consistency. A cuddly toy that looks perfect in samples but varies in mass production creates serious retail risks, including customer complaints and returns. Strong manufacturers implement multi-stage quality control systems covering materials, sewing, stuffing, and final inspection.

For cuddly toys, special attention should be paid to softness consistency, seam strength, filling balance, and facial alignment. Factories supplying retail should have clear QC standards, inspection records, and corrective action procedures. Random inspection alone is not enough—process control is key.

| QC Stage | What Is Checked | Retail Risk Reduced | Buyer Checkpoint |

|---|---|---|---|

| Incoming materials | Fabric & filling | Color/feel variation | Ask for IQC records |

| In-line QC | Sewing & stuffing | Shape defects | Observe production |

| Final inspection | Appearance & safety | Customer complaints | Review AQL standard |

| Needle detection | Metal safety | Recall prevention | Confirm testing |

How Important Are Safety Certifications and Compliance for Retail Distribution?

Safety compliance is non-negotiable in retail. Cuddly toys must meet strict standards depending on target markets, including ASTM F963 (USA), CPSIA, EN71 (EU), and REACH. A reliable manufacturer should be familiar with these standards and proactively guide buyers through compliance requirements.

Beyond test reports, retail-ready manufacturers understand labeling, age grading, and material traceability. They should work with accredited third-party labs and maintain documentation that supports customs clearance and retailer audits. Lack of compliance experience can delay launches or block market entry entirely.

| Compliance Area | Required Standard | Retail Importance | Buyer Verification |

|---|---|---|---|

| Toy safety | ASTM / EN71 | Market access | Review reports |

| Chemical safety | CPSIA / REACH | Child safety | Check materials |

| Labeling | Age & warnings | Retail approval | Confirm artwork |

| Testing labs | Accredited labs | Credibility | Verify lab name |

What Production Capacity and Lead Times Support Retail Seasonality and Scale?

Retail plush programs often involve seasonal spikes, promotional windows, and replenishment cycles. A suitable manufacturer must have sufficient capacity to handle volume increases without sacrificing quality. This includes labor availability, production lines, and material sourcing stability.

Lead time transparency is critical. Retail buyers should understand sample lead times, bulk production timelines, and buffer periods for testing and shipping. Manufacturers experienced in retail can help plan production calendars that align with launch dates and avoid last-minute risks.

| Factor | Retail Requirement | Manufacturer Capability | Buyer Action |

|---|---|---|---|

| Monthly capacity | Stable volume | Scalable lines | Confirm output |

| Lead time | Predictable | Process planning | Request schedule |

| Peak handling | Seasonal surge | Workforce flexibility | Ask about peaks |

| MOQ flexibility | Retail testing | Adjustable MOQ | Clarify upfront |

How Do Communication, Reliability, and After-Sales Support Impact Long-Term Retail Partnerships?

Strong communication is often the difference between a smooth retail partnership and a costly one. Retail buyers benefit from manufacturers who respond clearly, document changes, and proactively flag risks. This includes updates during sampling, production, and shipping stages.

After-sales support also matters. Retail programs may require reorders, packaging updates, or issue resolution after delivery. Manufacturers who provide consistent follow-up, quality feedback, and corrective support help brands maintain long-term retail relationships and reduce operational stress.

| Partnership Area | Strong Manufacturer Trait | Retail Benefit | Buyer Signal |

|---|---|---|---|

| Communication | Clear & timely | Fewer mistakes | Email clarity |

| Documentation | Structured records | Traceability | Process transparency |

| Problem handling | Solution-oriented | Risk control | Case examples |

| After-sales | Ongoing support | Long-term stability | Reorder handling |

Conclusion

Choosing a cuddly toy manufacturer for retail requires careful evaluation beyond price and samples. By focusing on retail experience, design support, quality systems, compliance readiness, capacity planning, and reliable communication, brands can build long-term partnerships that support consistent product performance and retail success.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com