Choosing the right factory for your brand’s plush collection is not a sourcing task—it is a brand strategy decision. From my experience working with brand owners, retailers, and licensors, the factory you choose will quietly shape your product quality, launch rhythm, and long-term scalability.

A plush collection is different from a single SKU. It requires consistent style language, stable quality standards, repeatable execution, and room to evolve. Many brands struggle not because designs are weak, but because the factory they chose was not aligned with their brand positioning or growth plan.

That is why factory selection should start with alignment, not quotations. Before evaluating price, capacity, or lead time, brands must first assess whether a factory’s manufacturing experience and product focus truly match what the brand is trying to build.

What Manufacturing Experience and Product Focus Align Best with Your Brand Positioning?

Not all plush factories are suitable for every brand. From my experience, the strongest brand–factory relationships happen when product focus and brand positioning overlap clearly, rather than when a factory claims to “do everything.”

The first point to assess is category experience. A factory that specializes in character plush, licensed products, or premium gift items brings very different strengths compared to one focused on low-cost promotional toys. Brands should look for factories that can clearly explain which plush categories they produce most often and why.

Next is style consistency. A reliable factory for brand collections can maintain consistent proportions, facial expressions, stitching style, and hand feel across multiple designs. This matters greatly when launching a cohesive collection rather than isolated products.

Manufacturing experience also shows in how factories handle repeatability. Brands need factories that are comfortable producing families of products—same style language, different sizes or characters—without quality drift. Experience with collection-based production is more important than the total number of SKUs shown in a showroom.

Another key factor is brand positioning awareness. Strong factories ask about your target market, price positioning, and distribution channels. They understand that a premium children’s brand, a lifestyle gift brand, and a mass retail brand require different material choices and workmanship standards.

Finally, assess focus versus breadth. A factory with a focused, relevant range is often more reliable than one with a wide but scattered product portfolio.

| Evaluation Factor | Misaligned Factory | Brand-Aligned Factory | Brand Benefit |

|---|---|---|---|

| Category experience | Generic plush claims | Clear category focus | Better execution |

| Style control | Inconsistent looks | Cohesive style output | Strong identity |

| Collection handling | One-off mindset | Series-based experience | Scalable launches |

| Brand awareness | Price-driven only | Positioning-aware | Better decisions |

| Product focus | Too broad | Relevant & focused | Long-term fit |

For brands, choosing a factory with the right experience and product focus creates structural stability. When the factory understands your category and positioning, every future decision—from materials to timelines—becomes easier and more aligned.

How Do Design Support, Pattern Making, and Sampling Capabilities Shape Collection Quality?

For a plush collection, quality is defined long before production begins. From my experience, brands achieve consistent, premium collections when factories provide strong design support, precise pattern making, and disciplined sampling systems—not just fast sample turnaround.

Design support determines whether concepts translate into manufacturable products. Brand-aligned factories review designs for proportion balance, character expression, and material feasibility. They flag risks early and propose adjustments that protect the brand look while improving durability and cost control.

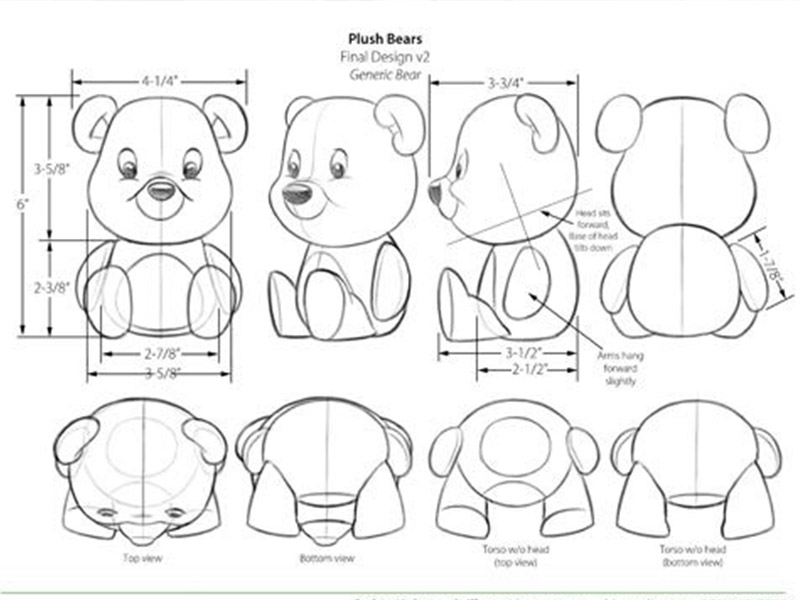

Pattern making is the technical backbone of collection consistency. Skilled pattern makers ensure that different SKUs share the same structural language—body ratios, seam placement, and silhouette—so the collection feels cohesive. Weak pattern work leads to visual inconsistency even if materials are the same.

Sampling capability then validates repeatability. Reliable factories treat sampling as a learning and locking process, not a cosmetic step. Development samples refine specs, while PPS confirms that approved designs can be reproduced on real lines using real materials.

Equally important is revision discipline. Factories that document changes, control versions, and confirm approvals prevent confusion when multiple styles are sampled in parallel. This is critical for collections with tight launch schedules.

Finally, speed must be balanced with accuracy. Fast samples are useful only if they reflect production reality. Brands benefit more from slightly slower, accurate samples than rushed samples that create false confidence.

| Capability Area | Weak Factory Signal | Brand-Ready Factory Signal | Collection Impact |

|---|---|---|---|

| Design support | Executes blindly | Reviews & advises | Better outcomes |

| Pattern making | Style-by-style | Unified structure | Cohesive look |

| Sampling purpose | Visual only | Lock specs & process | Repeatable quality |

| Revision control | Informal | Versioned approvals | Fewer errors |

| Speed vs accuracy | Fast but loose | Accurate & realistic | Reliable launch |

For brands, strong design, pattern, and sampling capabilities transform ideas into scalable collections. Factories that manage these stages with discipline help brands launch confidently and grow without sacrificing consistency.

What Quality Control Systems Ensure Consistency Across an Entire Plush Collection?

For a plush collection, quality is not about individual units—it is about how consistently every style, size, and color expresses the same standard. From my experience, brands run into trouble when factories manage QC per order instead of per collection.

The first requirement is collection-level quality standards. Reliable factories define shared workmanship rules—stitch density, seam finish, filling firmness, and facial alignment—that apply across all SKUs in the collection. This prevents quality gaps between “hero products” and secondary styles.

Next is reference control at scale. Approved golden samples must exist not only for each SKU, but also as a collection reference set. Inspectors and line leaders should compare outputs across styles to ensure the collection looks and feels cohesive, not just individually acceptable.

Process-based QC is essential. Strong factories embed inspections at critical points—cutting accuracy, embroidery placement, stuffing balance, and finishing—rather than relying on final inspection alone. As collections grow, in-process control is the only way to prevent drift across multiple lines and shifts.

Another key system is cross-SKU consistency checks. Collections often share fabrics, accessories, or construction methods. Reliable factories audit these shared elements regularly to ensure that changes in one SKU do not unintentionally affect others.

Finally, data and feedback close the loop. Defect trends should be tracked by collection, not just by order. This allows factories and brands to address root causes that affect the entire line, rather than fixing problems one product at a time.

| QC System Area | Weak Collection Control | Strong Collection Control | Brand Outcome |

|---|---|---|---|

| Quality standards | SKU-by-SKU | Collection-wide rules | Unified quality |

| Reference usage | Individual samples | Collection reference set | Cohesive look |

| Inspection method | Final-only | In-process + final | Early correction |

| Shared elements | Checked separately | Cross-SKU audits | Consistency |

| Data tracking | Order-based | Collection-based | Continuous improvement |

For brands, collection-level QC systems turn quality into a brand asset. Factories that manage quality holistically across all styles help ensure that every plush in the collection reinforces the same promise—on shelf, online, and over time.

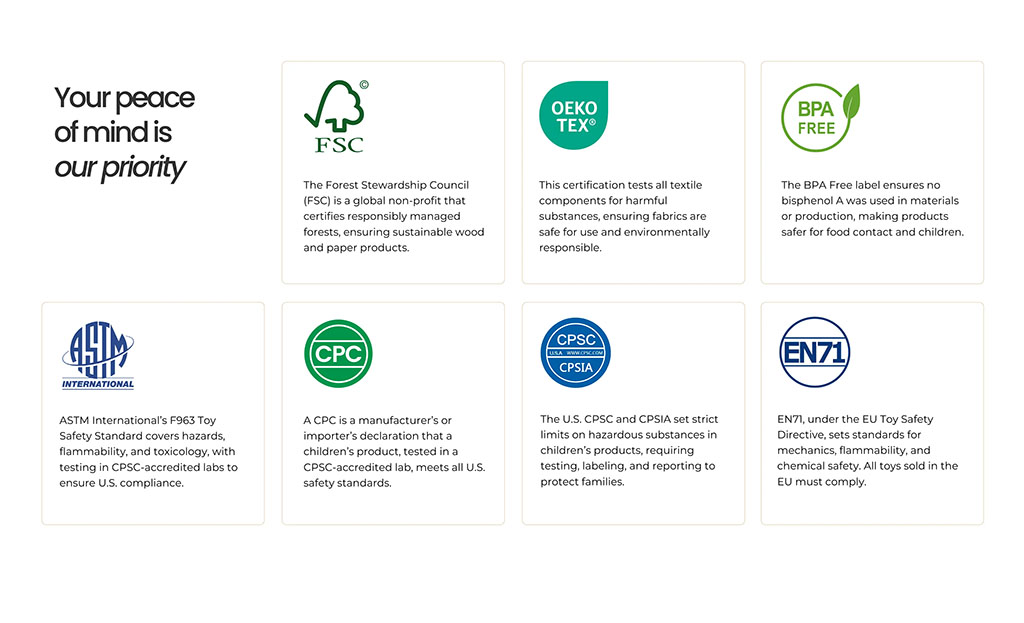

How Important Are Safety Certifications and Compliance for Your Target Sales Markets?

For a brand’s plush collection, safety certifications and compliance are not paperwork—they are market access requirements. From my experience, many brand delays and listing failures happen not because products are unsafe, but because compliance planning was left too late.

The first step is market-specific alignment. Different sales markets require different standards. A factory suitable for one region may not be prepared for another. Reliable brand partners understand which regulations apply to your target markets and plan materials, construction, and testing accordingly from the design stage.

Compliance must also be collection-wide, not SKU-by-SKU. When a plush collection shares fabrics, fillings, or accessories, compliance decisions affect multiple products. Strong factories manage approved material lists and ensure that shared components remain compliant across the entire collection lifecycle.

Documentation readiness is another critical factor. Brands need test reports, conformity declarations, and labeling information ready for audits, retailers, or e-commerce platforms. Factories with disciplined documentation systems reduce launch friction and internal review delays.

Change sensitivity matters as well. Any change in fabric supplier, dye lot, accessory, or construction method can impact compliance validity. Reliable factories enforce change control and notify brands before adjustments are made.

Finally, proactive compliance support adds value. Factories that monitor regulatory updates and advise brands early help prevent future rework as collections expand into new markets.

| Compliance Factor | Risky Factory Practice | Brand-Ready Factory Practice | Brand Benefit |

|---|---|---|---|

| Market knowledge | Generic answers | Market-specific clarity | Faster market entry |

| Scope management | SKU-only view | Collection-wide control | Consistent compliance |

| Documentation | On request | Organized & ready | Smooth approvals |

| Change control | Informal changes | Approval-based process | Reduced risk |

| Regulatory updates | Reactive | Proactive guidance | Future-proof growth |

For brands, compliance capability is a strategic filter when choosing a factory. Partners who treat safety and certification as ongoing systems—not one-time tasks—make it easier to launch, scale, and expand plush collections confidently.

What Production Capacity, MOQs, and Lead Times Fit Your Collection Launch Plan?

A plush collection launch succeeds or fails based on operational fit, not just design readiness. From my experience, many brands choose factories that can make good samples but cannot support the launch rhythm once multiple SKUs move into production at the same time.

The first factor is capacity alignment with launch scale. Brands should evaluate whether a factory can handle simultaneous production of multiple styles, sizes, or colorways—without pushing timelines or sacrificing quality. Capacity is not just about machine count; it includes trained labor, line flexibility, and scheduling discipline.

MOQ structure is equally important. Collection launches often involve testing several SKUs in parallel. Factories that insist on high MOQs for every style increase inventory risk and limit assortment flexibility. Brand-aligned factories offer reasonable entry MOQs with clear pathways to scale once sell-through is proven.

Lead time realism matters more than speed. Reliable factories break lead time into stages—sampling, material preparation, production, inspection, and shipping—so brands can plan marketing, logistics, and channel onboarding accurately. Overly aggressive lead times without explanation are a common risk signal.

Another key consideration is capacity buffering. Launches often change—best sellers emerge, weaker SKUs pause. Factories that can adjust production priorities within a defined framework support smoother launches and faster response to market feedback.

Finally, brands should assess how capacity scales after launch. A good factory for collections can explain how it supports reorders, volume increases, or seasonal spikes without restarting negotiations from zero.

| Launch Factor | Misaligned Factory | Collection-Ready Factory | Launch Advantage |

|---|---|---|---|

| Capacity handling | Single-SKU focus | Multi-SKU scheduling | Smooth rollout |

| MOQ flexibility | High per-style MOQ | Scalable entry MOQs | Lower inventory risk |

| Lead time quoting | One total number | Stage-based timeline | Better planning |

| Production flexibility | Rigid scheduling | Priority adjustment | Faster response |

| Post-launch scaling | Unclear | Defined growth path | Sustainable expansion |

For brands, the right factory fits the pace and uncertainty of a collection launch. When capacity, MOQs, and lead times are aligned with your launch plan, growth becomes controlled instead of chaotic.

How Do Communication, Transparency, and Long-Term Support Impact Brand–Factory Collaboration?

For a brand’s plush collection, collaboration quality often matters more than factory size. From my experience, many brand–factory relationships fail not because of technical limits, but because communication and transparency break down as projects grow.

The first foundation is clear, structured communication. Brand-ready factories confirm specifications, timelines, and decisions in writing, not just in chat messages. This reduces misunderstandings when multiple SKUs, revisions, and stakeholders are involved. Consistency in communication creates operational calm during busy launch periods.

Transparency builds trust over time. Reliable factories share progress updates, QC findings, and potential risks early—before they become problems. Transparency does not mean perfection; it means no surprises. Brands can plan better when they know what is happening in real time.

Long-term support also shows in problem ownership. Strong partners do not deflect responsibility when issues arise. They explain root causes, propose solutions, and implement preventive actions for future runs. This mindset is critical for collections that evolve season after season.

Another key factor is continuity. As teams change on either side, documented processes, references, and communication routines prevent quality or expectation drift. Factories that maintain institutional memory reduce dependence on individuals.

Finally, collaboration maturity supports growth. When factories understand a brand’s long-term vision, they proactively suggest improvements—cost optimization, material upgrades, or process refinements—that support scalability without compromising identity.

| Collaboration Area | Weak Factory Signal | Brand-Aligned Factory Signal | Brand Benefit |

|---|---|---|---|

| Communication | Ad-hoc messaging | Structured confirmations | Fewer errors |

| Transparency | Reactive updates | Proactive sharing | Predictable execution |

| Issue handling | Deflects blame | Owns & fixes | Faster recovery |

| Continuity | Person-dependent | Process-driven | Stable cooperation |

| Growth support | Order-only focus | Improvement mindset | Scalable partnership |

For brands, communication and transparency turn factories into true collaborators. Long-term support ensures that as your plush collection grows, execution remains aligned with brand values and market expectations.

Conclusion

Choosing the right factory defines how your plush collection looks, scales, and survives over time. Alignment, systems, and collaboration matter more than short-term gains.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com