Character-based plush toys are fundamentally different from generic plush products. They are not only physical goods, but also carriers of brand identity, emotional connection, and intellectual property value. Choosing the wrong factory can result in inaccurate characters, inconsistent quality, IP risks, and long-term brand damage. Choosing the right factory, on the other hand, enables scalable production while preserving the integrity of the character.

From my experience working with global brands, licensors, and influencer-led IP projects, successful character plush programs depend less on price negotiation and more on system capability, discipline, and collaboration maturity. This guide explains how B2B buyers should evaluate factories when developing character-based plush toys.

What Experience Should a Factory Have with Character and IP-Based Plush Projects?

A factory’s experience with character and IP-based plush projects is the most important qualification factor. Character plush is not about making something “cute”; it is about making something accurate, repeatable, and approved. Factories with real IP experience understand that visual deviation, even small ones, can cause rejection, delays, or licensing conflicts.

Experienced factories have worked with licensed characters, brand mascots, or creator-owned IP and are familiar with approval-driven workflows. They understand how to follow character sheets, respect proportion rules, and respond to detailed feedback without emotional resistance or design shortcuts. This experience significantly reduces trial-and-error during sampling.

Factories without character experience often rely on generic plush logic. They may adjust proportions to suit their own patterns or ignore subtle details that matter to brand owners. This usually leads to repeated revisions, extended timelines, and frustration on both sides.

| Key B2B Insight | What to Evaluate | Practical Guidance |

|---|---|---|

| Past project type | Licensed / character plush | Request real project samples |

| Approval experience | Brand-led revisions | Ask how approvals are handled |

| Design discipline | Accuracy over creativity | Avoid free interpretation |

| Risk control | Experience reduces risk | Prioritize proven factories |

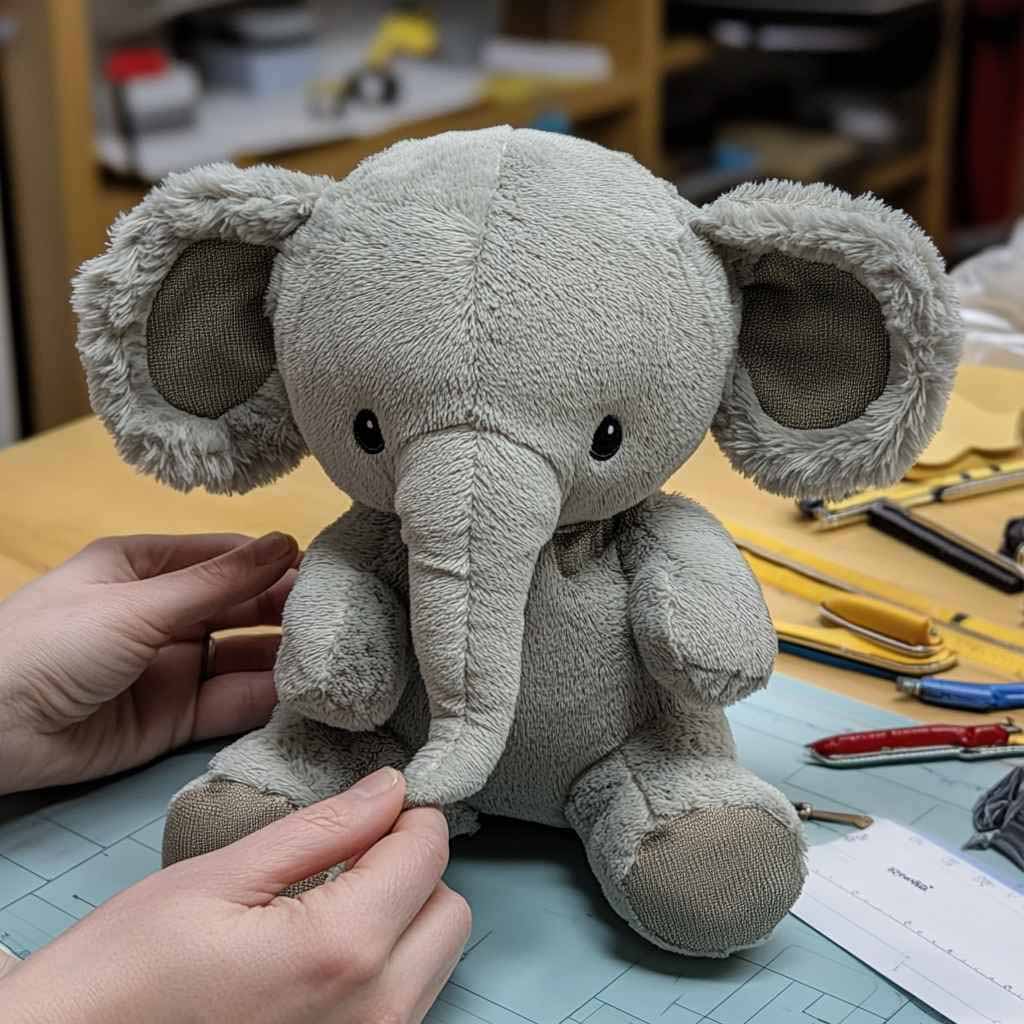

How Do Pattern Making and Sampling Capabilities Affect Character Accuracy?

Pattern making is where character accuracy is either secured or lost. Even the best design files cannot compensate for weak pattern engineering. For character-based plush toys, patterns must translate two-dimensional references into three-dimensional forms without distortion.

Strong pattern teams understand proportion control, seam placement, and volume balance. They know how to maintain head-to-body ratios, facial spacing, and posture consistency across different sizes. This is especially critical when characters need to be produced in multiple SKUs, such as small plush, medium plush, and keychain versions.

Sampling speed also matters, but accuracy matters more. A factory that produces fast but inaccurate samples creates more delays overall. Professional character factories typically invest more time in the first sample to reduce the number of revision rounds.

| Key B2B Insight | What to Evaluate | Practical Guidance |

|---|---|---|

| Pattern skill | 3D character control | Review sample accuracy |

| Size scalability | Multi-size consistency | Test different dimensions |

| Sampling logic | First-sample quality | Don’t reward speed alone |

| Revision handling | Structured feedback | Confirm correction workflow |

What Quality Control Systems Ensure Consistent Character Replication at Scale?

Mass production introduces a different challenge: consistency. Even if the approved sample is perfect, weak quality control can result in facial drift, uneven stuffing, or color deviation during bulk production. Character plush requires process-level control, not random inspection.

Reliable factories use pre-production samples, golden samples, and visual reference boards on production lines. Operators are trained to recognize character-critical zones such as eye spacing, mouth position, and silhouette outline. Without this training, subtle errors accumulate quickly across thousands of units.

Quality control checkpoints should be placed at cutting, sewing, stuffing, and final inspection stages—not only at the end. This layered approach is essential for character-based projects.

| Key B2B Insight | What to Evaluate | Practical Guidance |

|---|---|---|

| QC structure | Multi-stage control | Verify checkpoints |

| Visual references | Golden samples | Require line references |

| Operator training | Character awareness | Ask about training system |

| Bulk consistency | Controlled variance | Audit production output |

How Should Factories Handle IP Protection and Confidential Design Files?

IP protection is a non-negotiable requirement for character plush projects. Factories must treat design files, patterns, and samples as confidential assets, not reusable resources.

Professional factories implement internal access control, restrict file sharing, and prevent unauthorized photography or duplication. They understand that even internal misuse can lead to legal consequences for buyers. NDAs are standard, but behavior matters more than documents.

Buyers should assess whether the factory has clear internal policies for IP handling, including how files are stored, who can access them, and how samples are disposed of after projects end.

| Key B2B Insight | What to Evaluate | Practical Guidance |

|---|---|---|

| File control | Restricted access | Ask about internal policy |

| Sample handling | No reuse | Confirm disposal process |

| Legal awareness | IP sensitivity | Sign NDAs early |

| Trust factor | Long-term mindset | Avoid trading factories |

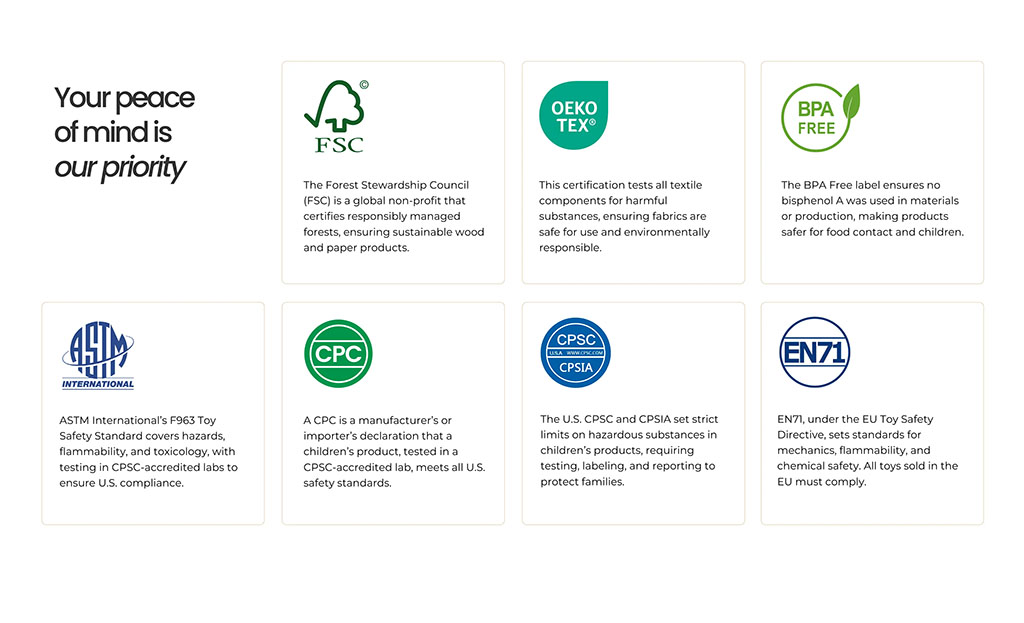

What Certifications and Safety Standards Are Critical for Character Plush Toys?

Character plush toys often target children, families, or mass retail, which means safety compliance is critical. Factories must be capable of meeting international standards such as ASTM F963, EN71, CPSIA, and relevant chemical regulations.

Character plush designs can increase risk due to accessories, appliqués, or unique shapes. Factories must understand how design decisions affect testing outcomes and adjust construction methods accordingly.

Buyers should confirm not only certification availability, but also the factory’s experience in preparing products for testing and responding to failures.

| Key B2B Insight | What to Evaluate | Practical Guidance |

|---|---|---|

| Target market | Required standards | Match to sales regions |

| Testing experience | Pre-test readiness | Ask about past failures |

| Design awareness | Risk prevention | Review accessories early |

| Compliance support | Documentation | Ensure report handling |

How Do Communication, Revision Speed, and Project Management Impact Long-Term Success?

Character plush projects are rarely one-off orders. They evolve through revisions, new sizes, seasonal updates, and future collections. This makes communication and project management just as important as manufacturing capability.

Strong factories provide clear timelines, structured feedback loops, and proactive communication. They document revisions, track version changes, and ensure continuity even if team members change. This stability is essential for long-term collaboration.

Factories that respond slowly, lose context, or rely on informal communication often become bottlenecks as projects scale.

| Key B2B Insight | What to Evaluate | Practical Guidance |

|---|---|---|

| Communication clarity | Structured updates | Assign dedicated manager |

| Revision speed | Predictable timing | Confirm response standards |

| Documentation | Version control | Track sample history |

| Partnership value | Long-term fit | Think beyond first order |

Conclusion

Choosing the right factory for character-based plush toys is not a cost-driven decision, but a long-term brand protection strategy. Factories with proven character experience, disciplined pattern development, structured quality control, and strict IP protection systems are essential for maintaining character accuracy and scaling production safely. For brands and IP owners, the right manufacturing partner ensures consistency, reduces approval risk, and supports sustainable growth across multiple product cycles.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com