Choosing the right fabric is one of the most important decisions in custom stuffed animal development. Fabric influences appearance, softness, safety, durability, cost, and how customers perceive product quality. For brands targeting Western markets—especially the U.S., EU, UK, and Japan—fabric selection must also support compliance, washability, and long-term performance.

This guide explains how factories evaluate different plush fabrics, what buyers should consider when selecting materials, and how to make decisions that balance quality, safety, and cost.

What Performance Requirements Should Guide Fabric Selection for Stuffed Animals?

Before choosing any material, you need to define the performance expectations of the product. This means understanding how the stuffed animal will be used, who will use it, and what durability standards it must meet. For example, baby plush toys require extremely soft fabrics, high seam strength, saliva-safe dyes, and embroidered details. Meanwhile, plush toys for collectors or licensed merchandise may require aesthetic accuracy and specialty textures rather than extreme durability.

Factories evaluate fabrics based on functional performance: softness, abrasion resistance, pilling behavior, washability, stretch, and long-term shape retention. A plush toy sold in retail stores must maintain its appearance even after repeated handling and transportation. Toys with long-pile fur must resist shedding, while character-based plush must express accurate emotion through facial texture and pile direction.

Defining your performance goals early helps your factory recommend the correct fabric type and density. This also prevents expensive resampling later in development.

| Performance Requirement | Fabric Consideration | Impact on Product |

|---|---|---|

| Softness | Minky, velboa | Comfort & tactile feel |

| Durability | Short-pile fabrics | Longer lifespan |

| Washability | Heat-stable materials | Easy care |

| Child-safe | Certified dyes & fabrics | Meets compliance |

| Visual accuracy | Texture + color match | Brand consistency |

How Do Common Plush Fabrics Differ in Texture, Durability, and Application?

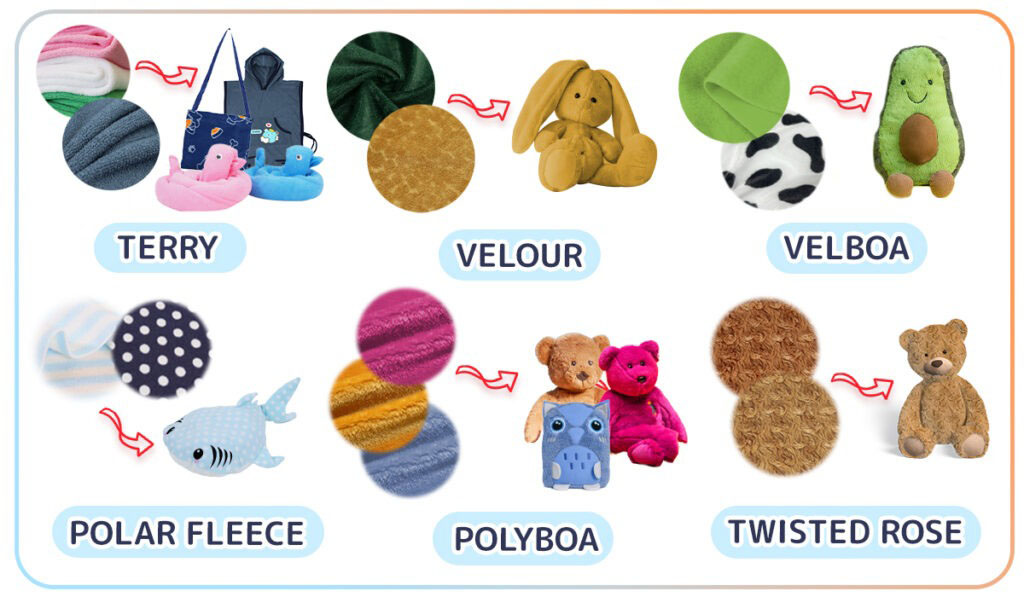

Different materials serve different purposes in plush toy manufacturing. Understanding these differences helps you choose a fabric that matches your project’s requirements. Velboa, for example, is affordable and versatile for mass production, while minky offers premium softness popular in baby toys. Faux fur delivers realism and visual depth but is harder to sew and requires advanced pattern skills.

Sherpa, fleece, and brushed fabrics create a cozy appearance ideal for winter-themed plush or animals like lambs and polar bears. Specialty fabrics such as corduroy, felt blends, or textured knits bring unique design options but may increase cost or require additional reinforcement during sewing.

Each fabric type performs differently during cutting, sewing, stuffing, and pattern shaping. This is why factories often test multiple materials during early sampling.

| Fabric Type | Texture & Feel | Durability | Typical Use Case |

|---|---|---|---|

| Velboa | Smooth, short-pile | High | Retail plush, mascots |

| Minky (2–3mm) | Ultra-soft | Medium | Baby toys, premium plush |

| Long-pile faux fur | Fluffy, realistic | Medium–Low | Animals, luxury designs |

| Fleece / Sherpa | Warm, cozy | Medium | Seasonal plush |

| Corduroy / Canvas | Firm texture | High | Clothing, accessories |

| Specialty knits | Unique appearance | Varies | Character costumes |

What Role Do Pile Height, Density, and Hand-Feel Play in Final Product Quality?

Pile height (length of the fibers), density (the amount of fiber packed per area), and hand-feel (how the fabric feels when touched) are key indicators of fabric quality. Soft, dense fabrics create premium plush toys, while lower-density materials may feel cheaper, thinner, or less durable.

Short-pile fabrics (0.5–3mm) provide clean facial embroidery, crisp shapes, and excellent durability. Dense minky fabrics offer a velvety feel, while medium-pile materials (5–10mm) create plushness without compromising shape stability. Long-pile faux fur requires high fiber density to avoid shedding and ensure consistent body shape.

The hand-feel must match the product’s emotional appeal. Baby plush should feel cloud-soft, while realistic animals require lifelike fur textures. Pile height also affects production because long-pile fabrics require trimming, brushing, and precise seam alignment.

| Pile Height | Advantages | Considerations |

|---|---|---|

| Short (0.5–3mm) | Sharp details, strong structure | Best for faces & logos |

| Medium (3–10mm) | Balanced plushness | Moderate complexity |

| Long (10mm+) | Realistic texture | Harder to sew, sheds easily |

How Do Safety, Compliance, and Washability Standards Influence Fabric Choices?

Fabric selection for stuffed animals must follow regulatory standards that vary by country. For example, the U.S. requires compliance with ASTM F963 and CPSIA; Europe uses EN71; the UK requires UKCA; and Japan follows ST standards. All of these specify restrictions for flammability, heavy metals, chemical content, and durability.

Washability is also important, especially for children’s toys. Colors must remain stable after washing, fabrics must resist pilling, and trims must withstand repeated handling. Plush fabrics used for infant or toddler markets must be hypoallergenic, non-toxic, and free from shedding fibers.

Factories test materials for seam strength, color fastness, saliva resistance, and fabric stability. Choosing compliant fabrics from the beginning avoids unexpected test failures and costly redesigns.

| Compliance Requirement | Fabric Implication | Market Relevance |

|---|---|---|

| ASTM F963 / CPSIA | Safe dyes & durable seams | U.S. |

| EN71 | Chemical testing & flammability control | EU |

| UKCA | Safety labeling rules | UK |

| Saliva resistance | Baby-safe plush | Infant toys |

| Machine wash test | Stable color & texture | Retail plush |

How Can Color Fastness, Dyeing Methods, and Pantone Matching Ensure Consistency?

Color accuracy is essential, especially for licensed characters and branded plush. Factories use Pantone codes, fabric swatches, or approved color chips to ensure the fabrics match the brand’s standards. Inaccurate color can cause product rejection, brand damage, or consistency issues between batches.

Color fastness—the resistance of fabric dye to washing, rubbing, or sunlight—must meet international testing standards. Poor-quality dyes can bleed during production or after purchase, leading to customer dissatisfaction and safety concerns.

Factories may use piece-dyed, solution-dyed, or yarn-dyed methods, each influencing cost and consistency. For highly specific colors, custom dyeing may be required, but this increases cost and minimum order quantities.

| Color Control Factor | Benefit | Importance |

|---|---|---|

| Pantone matching | Brand consistency | High |

| UV fastness | Prevents fading | Medium–High |

| Wash fastness | Ensures durability | High |

| Custom dyeing | Exact color accuracy | Very high |

| Lot consistency | Same color across batches | Critical |

How Should Cost, Lead Time, and Supplier Availability Factor Into Fabric Decisions?

While premium fabrics create beautiful plush toys, they may come with longer lead times, higher minimum order quantities (MOQs), or limited supplier availability. Buyers must balance quality expectations with production schedules and cost limits.

Velboa offers excellent cost efficiency and short lead times due to widespread availability. Minky is slightly more expensive but still stable in supply. Faux fur and specialty textures may require longer sourcing times, and custom dyeing can add 2–4 weeks to the manufacturing schedule.

Fabric decisions also influence labor cost. Long-pile materials require precision sewing and more complex finishing. Each fabric type affects cutting efficiency, pattern complexity, and sewing speed—contributing to final production cost.

| Cost Factor | Fabric Impact | Result |

|---|---|---|

| Lead time | Specialty fabrics take longer | Extended production cycle |

| Cost per meter | Higher for minky & faux fur | Higher unit cost |

| Supplier availability | Common vs. rare fabrics | Stability of supply |

| MOQ | Custom colors require large orders | Higher upfront cost |

| Labor intensity | Long-pile & textured fabrics | Increased sewing time |

Conclusion

Choosing the right fabric for custom stuffed animals is a strategic decision that impacts quality, safety, cost, production speed, and customer satisfaction. By understanding performance needs, fabric types, material behavior, compliance requirements, and sourcing considerations, buyers can collaborate more effectively with factories and develop plush toys that look beautiful, feel premium, and meet global standards.

Factories like Kinwin help brands navigate these decisions with expert guidance on fabric sourcing, testing, and prototyping—ensuring every plush toy is both high-quality and market-ready.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com