For retail buyers, choosing a stuffed toys wholesale partner is not just about sourcing products—it is about building a stable supply system. From my experience working with retailers, brands, and e-commerce sellers, many retail problems such as stock-outs, inconsistent quality, or margin pressure can be traced back to the wrong wholesale partner.

Retail markets demand a balance of price, consistency, safety, and speed. A supplier that works well for promotional or one-off orders may fail when faced with continuous retail replenishment. That is why retail buyers must evaluate wholesale partners differently from OEM or custom project suppliers.

The first step is understanding what types of wholesale stuffed toy suppliers actually serve retail markets best, because not all “wholesale” suppliers are built for retail-scale operations.

What Types of Wholesale Stuffed Toy Suppliers Serve Retail Markets Best?

In the retail context, the best wholesale stuffed toy partners are those designed for repeatability and scale, not just low pricing. From my experience, retail buyers should focus less on supplier labels and more on how the supplier operates day to day.

The first common type is factory-direct wholesale suppliers. These suppliers own or control production and can offer better cost stability and quality consistency. They are well suited for retailers with predictable volumes, private-label needs, or long-term SKUs. Their strength lies in production control, but they often require clearer forecasts and MOQs.

The second type is integrated wholesale distributors. These suppliers source from multiple factories and focus on ready-to-ship or fast-replenishment items. They are useful for retailers that need flexibility, seasonal rotation, or lower initial risk. However, quality consistency can vary if supplier control is weak.

A third category is export-focused OEM wholesalers. These suppliers combine manufacturing with wholesale programs designed specifically for overseas retail markets. They understand safety standards, packaging norms, and logistics requirements, making them strong partners for cross-border retail.

Retail buyers should be cautious with trading-only suppliers that do not control production. While prices may look attractive, risks around consistency, lead time, and compliance are higher—especially as volumes grow.

| Supplier Type | Operational Focus | Strengths for Retail | Key Risks |

|---|---|---|---|

| Factory-direct wholesalers | Own production | Stable quality & cost | Higher MOQ |

| Integrated distributors | Multi-factory sourcing | Flexibility & speed | Inconsistent quality |

| Export OEM wholesalers | Retail-ready programs | Compliance & logistics | Needs volume planning |

| Trading-only suppliers | Price-driven sourcing | Low entry cost | Low control |

| Mixed-model suppliers | Hybrid approach | Balanced flexibility | Depends on management |

For retail buyers, the best wholesale partners are those that think in retail cycles, not one-time deals. Suppliers who understand replenishment rhythm, shelf consistency, and long-term SKU management create far more value than those focused only on unit price.

How Can Retail Buyers Evaluate Product Quality and Consistency at Scale?

Evaluating stuffed toy quality for retail is not about inspecting one perfect sample—it is about predicting what thousands of units will look and feel like over time. From my experience, many retail issues arise because buyers approve samples emotionally instead of evaluating system-level consistency.

The first step is to assess reference control. Strong wholesale partners work from a locked reference sample that is physically present on the production floor and used by QC teams across batches. If a supplier relies only on photos or past memory, quality drift becomes likely as orders repeat.

Next is batch consistency evaluation. Retail buyers should request multiple samples from different production times or lines, not just one. Small variations in fabric pile, stuffing density, or facial placement become obvious when samples are compared side by side. Reliable suppliers expect this request and support it.

Material stability is another key factor. Wholesale partners serving retail well can explain how they manage fabric batches, dye lots, and filling rebound. If materials change between shipments without clear communication, shelf appearance becomes inconsistent and customer complaints increase.

Process-based quality control matters more than final inspection alone. Buyers should ask how quality is checked during cutting, sewing, stuffing, and finishing. In-process control prevents large-scale issues instead of sorting defects at the end.

Finally, evaluate repeatability under reorder pressure. A supplier that performs well on the first order but struggles on reorders is not retail-ready. Ask how they handle repeat SKUs, seasonal peaks, and workforce stability.

| Evaluation Area | Weak Wholesale Partner | Retail-Ready Wholesale Partner | Buyer Benefit |

|---|---|---|---|

| Reference control | Photos only | Physical locked sample | Visual consistency |

| Sample evaluation | Single prototype | Multi-batch comparison | Predictable quality |

| Material stability | Substitutions allowed | Batch-controlled sourcing | Shelf uniformity |

| QC approach | End-only inspection | In-process + final QC | Fewer defects |

| Reorder handling | Quality drift | Stable repeat output | Brand trust |

For retail buyers, quality evaluation must shift from “Is this sample good?” to “Can this quality be repeated reliably?” Wholesale partners that operate with reference discipline, material control, and process-based QC are far more capable of supporting long-term retail programs.

What Pricing Structures and MOQs Work Best for Retail Wholesale Cooperation?

In retail wholesale cooperation, pricing and MOQ are not just numbers—they define cash flow pressure, replenishment flexibility, and long-term margin stability. From my experience, many retail partnerships fail not because prices are high, but because pricing structures do not match retail operating reality.

The most retail-friendly pricing models are tiered pricing structures. These reward volume growth without forcing large upfront commitments. Strong wholesale partners set clear price breaks based on order quantity, allowing retailers to test SKUs, then scale confidently as sell-through improves.

MOQ design is equally important. Retail-ready wholesalers understand that initial orders and replenishment orders serve different purposes. Lower MOQs for first orders reduce risk and speed market entry, while higher—but reasonable—MOQs for reorders support production efficiency and cost control. Suppliers that insist on one rigid MOQ often struggle to support retail growth cycles.

Another key factor is price stability over time. Retailers need predictable margins to plan promotions and replenishment. Wholesale partners that frequently adjust prices due to internal inefficiency or poor material planning create risk. Reliable partners explain what may cause price changes and how long pricing remains valid.

Packaging and logistics should be reflected transparently in pricing. Retail buyers benefit when wholesale quotes clearly separate product cost, packaging options, and shipping terms, rather than bundling everything into a single unclear number.

Finally, consider SKU-level pricing logic. Retail assortments often include core SKUs and seasonal items. Strong wholesale partners price these differently, recognizing different volume expectations and lifecycle lengths.

| Pricing & MOQ Factor | Weak Wholesale Practice | Retail-Optimized Practice | Buyer Advantage |

|---|---|---|---|

| Pricing model | One fixed price | Tiered volume pricing | Scalable margins |

| Initial MOQ | High from first order | Low test MOQ | Reduced risk |

| Reorder MOQ | Same as first order | Optimized for scale | Cost efficiency |

| Price stability | Frequent changes | Defined validity period | Planning confidence |

| Cost transparency | Bundled pricing | Clear cost breakdown | Margin control |

For retail buyers, the best wholesale pricing structures are those that grow with your business. Partners who design MOQs and pricing around retail realities—testing, replenishment, and seasonality—create healthier margins and more sustainable long-term cooperation.

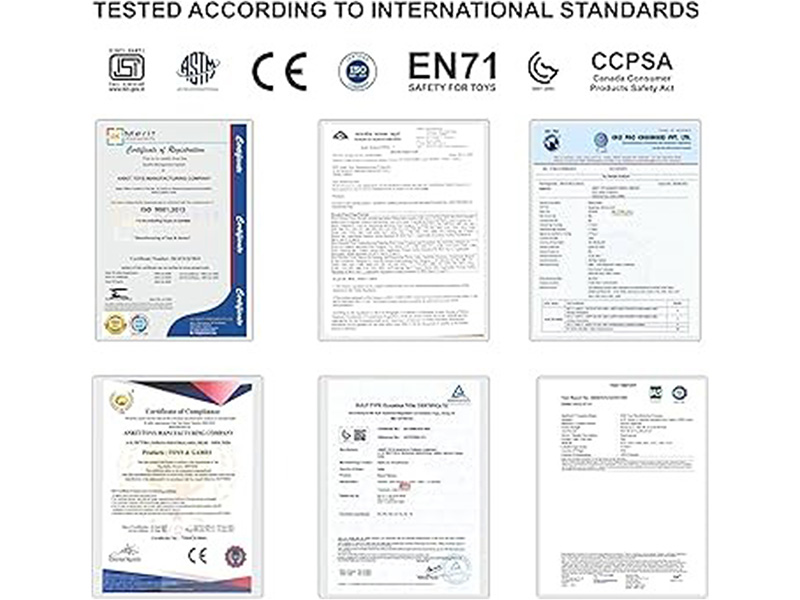

How Do Safety Certifications and Compliance Impact Retail Readiness?

For retail buyers, safety certifications are not a formality—they are a gatekeeping requirement. From my experience, many wholesale suppliers can produce stuffed toys, but far fewer are truly retail-ready because they lack compliance discipline.

Retail markets operate under strict liability rules. If a stuffed toy fails safety requirements, the retailer—not the factory—often bears the first reputational and financial impact. This is why professional retail buyers evaluate compliance capability as part of supplier qualification, not after ordering.

The first requirement is market-specific certification knowledge. Retail-ready wholesale partners clearly understand which standards apply to which markets. For example, U.S. retail requires ASTM F963 and CPSIA compliance, while EU retail requires EN71 and REACH alignment. Suppliers who speak in general terms like “we can pass tests” without referencing specific standards introduce risk.

Age grading plays a critical role in retail readiness. Products intended for young children require stricter construction rules—embroidered features, reinforced seams, and controlled filling access. Wholesale partners who proactively recommend safer design options demonstrate retail experience and reduce redesign cycles.

Documentation quality is another key factor. Retailers often need test reports, CPC or declarations, and traceability records quickly—sometimes for audits or platform onboarding. Suppliers that manage compliance documentation systematically enable faster listing and fewer delays.

Finally, compliance consistency across batches matters. A product that passes testing once but changes materials later is a hidden risk. Retail-ready partners lock materials and construction to tested samples and communicate clearly before any change.

| Compliance Factor | Weak Wholesale Supplier | Retail-Ready Wholesale Partner | Retail Benefit |

|---|---|---|---|

| Standards knowledge | Generic compliance claims | Market-specific expertise | Faster approval |

| Age grading | Decided late | Designed from start | Lower recall risk |

| Documentation | Provided on request | Organized & ready | Easy onboarding |

| Testing approach | One-time testing | Batch-aligned testing | Ongoing compliance |

| Change control | Silent substitutions | Pre-change approval | Brand protection |

For retail buyers, compliance capability directly affects speed to shelf. Wholesale partners who treat safety and certification as part of product development—not an afterthought—make retail expansion smoother, safer, and more predictable.

What Logistics, Lead Time, and Inventory Support Should Retailers Expect?

For retail buyers, logistics and lead time are not back-end details—they directly affect sell-through, replenishment speed, and cash flow health. From my experience, many wholesale partnerships break down not because of product issues, but because delivery systems cannot support retail rhythms.

Lead time predictability comes first. Retail-ready wholesale partners do not simply quote “production time.” They explain order confirmation lead time, production lead time, inspection time, and shipping time as a complete timeline. This allows retailers to plan promotions, launches, and replenishment accurately.

Logistics flexibility is equally important. Strong wholesale partners can support different shipping models—FOB, CIF, DDP—and help retailers choose based on urgency and cost. They also understand retailer-specific requirements such as carton labeling, palletization, and documentation accuracy, which reduce delays at warehouses and fulfillment centers.

Inventory support is a major differentiator. Retail-focused wholesalers often offer buffer stock, partial shipments, or rolling production plans for core SKUs. This helps retailers respond to demand spikes without committing to excessive upfront inventory.

Another key point is peak-season readiness. During holidays or promotional periods, logistics congestion increases. Reliable partners plan capacity and shipping windows in advance, rather than reacting after delays occur.

Finally, transparency during fulfillment matters. Retailers benefit when suppliers provide production updates, inspection results, and shipment tracking proactively. This visibility enables early problem-solving instead of last-minute crisis management.

| Logistics Factor | Weak Wholesale Partner | Retail-Ready Wholesale Partner | Retail Advantage |

|---|---|---|---|

| Lead time clarity | Single vague timeline | Step-by-step breakdown | Better planning |

| Shipping options | One default method | Multiple logistics models | Cost control |

| Inventory support | Order-only supply | Buffer & rolling plans | Faster replenishment |

| Peak season handling | Reactive | Pre-planned capacity | Fewer stock-outs |

| Fulfillment visibility | Minimal updates | Proactive reporting | Operational confidence |

For retailers, the right wholesale partner supports not just delivery, but retail continuity. Suppliers who understand lead-time structure, logistics flexibility, and inventory support help retailers maintain momentum instead of constantly managing supply risk.

How Can Long-Term Wholesale Partnerships Support Retail Growth and Brand Stability?

For retailers, the real value of a wholesale partner is not in the first order—it is in what happens after the first few reorder cycles. From my experience, long-term wholesale partnerships create stability that directly supports retail growth, margin control, and brand consistency.

The first benefit is SKU stability. Reliable wholesale partners help retailers maintain consistent core products across seasons. This means stable materials, repeatable quality, and predictable costs. When SKUs stay consistent, retailers reduce customer complaints, improve reviews, and build trust with repeat buyers.

Long-term partners also support data-driven replenishment. As sales history accumulates, strong wholesalers adjust production planning, MOQ structure, and inventory support based on real demand. This reduces overstock risk while improving availability of best-selling items.

Another key advantage is product development continuity. Wholesale partners who understand a retailer’s brand positioning can suggest new designs, seasonal variations, or packaging updates that align with existing assortments. This shortens development cycles and keeps collections fresh without starting from zero each time.

Operational efficiency improves over time as well. Established partners require less communication to execute correctly because specifications, standards, and expectations are already aligned. This reduces internal workload for retail teams and improves speed to market.

Finally, long-term partnerships protect brand reputation. Wholesale partners who invest in compliance consistency, QC discipline, and transparent communication help retailers avoid recalls, delivery disruptions, and public-facing issues that damage brand credibility.

| Partnership Value Area | Short-Term Supplier | Long-Term Wholesale Partner | Retail Impact |

|---|---|---|---|

| SKU consistency | Changes order to order | Stable repeat standards | Brand trust |

| Replenishment | Reactive | Data-informed planning | Better cash flow |

| Product evolution | One-off offers | Brand-aligned suggestions | Faster innovation |

| Operational load | High coordination | Streamlined execution | Team efficiency |

| Risk management | Transactional | Proactive control | Reputation protection |

For retailers, the strongest wholesale partnerships act as an extension of the retail operation. When suppliers grow with your business, they support not only sales volume—but also brand stability, operational confidence, and long-term profitability.

Conclusion

The best stuffed toys wholesale partners help retailers grow through consistent quality, retail-ready compliance, flexible logistics, and long-term collaboration—not just low prices.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com