When buyers ask me which stuffing we use in most soft toys, the answer is clear and simple: polyester fiberfill. I’m Amanda from Kinwin in China. In this guide, I’ll explain why polyester dominates, how it compares with cotton, wool, and kapok, what safety standards apply, how density and denier change the “hug feel,” and which recycled or hypoallergenic variants work best for eco lines and baby products.

What stuffing material dominates modern soft toy manufacturing?

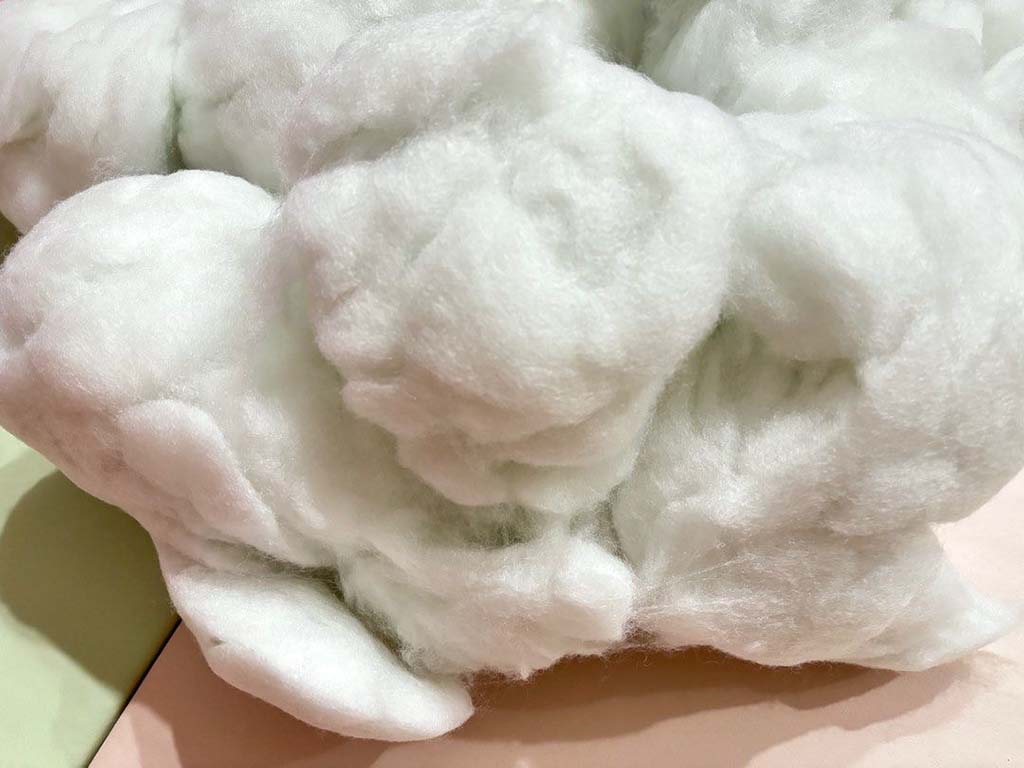

Across global plush manufacturing—mass retail, e-commerce, and licensed IP—polyester fiberfill (often called polyfill or PP cotton in Asia) is the standard. It delivers a rare mix of softness, resilience, cleanliness, and price stability, and it scales well for factories and brand programs. Polyester fiberfill arrives as clean, fluffy fibers engineered to trap air pockets, which makes soft toys feel cushioned yet lightweight. It resists moisture better than many naturals, returns to shape after compression, and washes predictably when the toy’s construction is designed for machine care. For most SKUs, we use fiberfill alone; for sitting posture or premium “weight,” we add small sealed pellet pouches in the base, then wrap with fiberfill to keep the outside cloud-soft. Because supply is global and quality grades are consistent, polyester supports repeat orders, tight timelines, and unit-cost control—critical for retailers and fast-moving DTC brands.

Dominant stuffing in modern plush

| Stuffing type | Share in mainstream toys | Why it leads | Typical use cases |

|---|---|---|---|

| Polyester fiberfill (virgin/rPET) | Very high | Soft, clean, resilient, scalable, cost-steady | Baby plush, kids’ plush, collectibles |

| Natural fibers (cotton/wool/kapok) | Low to niche | Brand story, tactile nuance | Artisanal or premium décor |

| Pellets/beads (with fiberfill) | Add-on component | Weight/posture tuning | Sitting toys, weighted variants |

| Foam inserts (with fiberfill) | Add-on component | Shape definition (muzzles, big heads) | Character plush, mascots |

Why is polyester fiberfill the most widely used option?

Polyester fiberfill wins because it solves five big problems at once: feel, durability, hygiene, wash care, and supply. Fine, sometimes hollow-conjugate fibers create springy loft without heaviness, so a plush can be squished and still rebound. Polyester absorbs less water than cotton or wool, helping toys dry faster and stay odor-free when used with proper care instructions. It also keeps its loft during long shipments and warehouse storage, which prevents flat or lumpy toys at delivery. From a manufacturing view, polyester is easy to meter by gram weight and zone density (firmer head for facial definition, medium body for hugs), which gives consistent hand-feel across large batches. Cost matters too: polyester offers a reliable price curve and broad supplier base, supporting reorders and seasonality with fewer surprises. For eco stories, recycled polyester (rPET) fiberfill maintains the same performance while adding a verified sustainability claim.

Why polyester fiberfill dominates

| Benefit area | What polyester provides | What buyers gain |

|---|---|---|

| Softness | Fine fibers, smooth squeeze-and-rebound | “Cloud” feel customers notice immediately |

| Durability | Resists clumping when specified/filled correctly | Longer shelf life and better reviews |

| Hygiene | Lower moisture uptake, low-odor clean grades | Safer perception, easier care |

| Washability | Predictable results in gentle cycles | Clear care labels, fewer returns |

| Scalability | Global availability, stable pricing | On-time reorders, stable unit costs |

How does polyester compare with cotton, wool, and kapok?

Natural fillings have character, but each carries production and care trade-offs. Cotton fiber feels familiar and dense, yet it absorbs moisture, compacts faster, and can clump after washing. Wool is springy and warm but may felt, shrink, or trigger allergies; it’s better for adult décor than mouthing-age toys. Kapok is feather-light and silky, but it’s delicate to process and harder to control in mass production; consistency and hygiene need extra vigilance. By contrast, polyester fiberfill offers consistent cleanliness, rebound, and wash behavior, which is why most brands reserve naturals for storytelling SKUs while keeping polyester for the core line. When a plush must be baby-friendly, machine-washable, and cost-predictable, polyester wins.

Polyester vs natural fillings

| Filling | Softness feel | Wash/Care reality | Production risk | Best fit |

|---|---|---|---|---|

| Polyester fiberfill | Cloud-soft, springy | Handles gentle wash, fast dry | Low (broad suppliers) | Baby/kids plush, mass retail, DTC core lines |

| Cotton fiber | Dense, familiar | Holds moisture, clumps if over-washed | Medium (batch variability) | Small décor, artisanal pieces |

| Wool | Warm, lively spring | Felts/shrinks; allergy concerns | Medium | Adult décor/collectibles (care labels) |

| Kapok | Ultra-light, silky | Delicate, QC intensive | Higher | Niche eco pillows/decor |

What safety and compliance standards govern stuffing materials today?

Stuffing must meet the same toy safety regime as outer fabrics and trims. For EU markets, manufacturers follow EN 71-1/2/3 (mechanical/flammability/chemicals). For the USA, ASTM F963 and CPSIA apply, including limits for heavy metals and phthalates. Many retailers request REACH alignment, and baby-focused programs may ask for OEKO-TEX® Standard 100 on textiles. Practically, this means fiberfill must be clean, low-odor, and free of restricted substances; seams must not leak fibers; and any pellets must be double-contained inside stitched pouches. Factories like Kinwin run needle detection, seam pull tests (often ≥90N on stress points), and random stuffing inspections to ensure there are no hard contaminants or sharp fragments. If you change a critical input (fiber grade, pellet type), expect the compliance plan to be reconfirmed before bulk.

Compliance focus for stuffing

| Area | What labs/factories check | Why it matters |

|---|---|---|

| Mechanical safety | Seam strength, no leaks, secure pellet pouches | Prevents choking hazards |

| Chemical safety | Restricted substances in fibers/finishes | Legal sale and retailer acceptance |

| Flammability | Fabric behavior under flame | Required for most markets |

| Hygiene/cleanliness | Low lint/odor, no foreign matter | Safer for babies and sensitive users |

| Traceability | Supplier IDs, batch records, certifications | Faster approvals, fewer delays |

How do density and fiber denier affect softness and resilience?

Two variables define the “hug”: fiber denier (thickness) and fill density (how much fiber per zone). Lower denier (finer fibers) bends more easily, creating a silky squeeze and smoother rebound; higher denier feels firmer and springier. Density controls shape: the head is usually medium-firm for facial definition, the body medium for cuddling, and limbs lighter for a relaxed drape. Over-stuffing makes toys stiff and increases seam stress; under-stuffing leads to hollow corners and a tired look. We set gram targets by size and zone maps so every unit in a batch feels the same, even months later. For sitting plush, we add pellet pouches to the base and then buffer them with fiberfill to preserve a soft exterior.

Denier & density tuning

| Parameter | Typical choice for soft toys | What the user feels | Factory note |

|---|---|---|---|

| Fiber denier | ~0.7–1.0D microfiber polyester | Silky glide, gentle rebound | Finer fiber ⇒ premium hand |

| Head density | Medium-firm | Clear face shape | Protects embroidery geometry |

| Body density | Medium | Huggable, cushioned | Primary comfort zone |

| Limb density | Light-medium | Relaxed, natural drape | Easier posing |

| Base weighting | Small pellet pouch + fiberfill | Stable sitting, soft exterior | Double containment for safety |

Which recycled or hypoallergenic variants meet eco and baby-grade needs?

For eco lines, recycled polyester (rPET) fiberfill is the most practical upgrade: it keeps the same softness and resilience as virgin fiber while adding a credible recycled-content claim. Choose suppliers with GRS or equivalent documentation and keep batch certificates for audits. For baby programs and sensitive-skin ranges, prioritize low-lint, low-odor grades with clean finishing; pair with short-pile, toy-grade outer fabrics to reduce lint further. If you want a stronger wellness message, you can combine rPET fill with OEKO-TEX®-certified fabrics, and use recycled plastic pellets where weighted posture is needed (not for mouthing ages). Label care clearly—cold wash, gentle cycle, air dry—so the plush stays soft and safe through real family use.

Eco & baby-friendly stuffing choices

| Variant | Why choose it | Where it fits best | Key documentation |

|---|---|---|---|

| rPET polyester fiberfill | Eco claim with same performance | Core eco lines, retailers with targets | GRS certificates |

| Low-lint clean grades | Less fiber migration for babies | Baby plush, loveys, nursery sets | Supplier hygiene records |

| Recycled plastic pellets | Circularity for weighted posture | Older-age sitting plush/collectibles | Material specs + QC |

| Hypoallergenic positioning | Low-odor, clean fill + short-pile fabric | Sensitive-skin SKUs | OEKO-TEX® on textiles (where applicable) |

Conclusion

The most commonly used stuffing for soft toys is polyester fiberfill—because it’s soft, resilient, clean, washable, scalable, and cost-steady. Naturals can add story, but polyester is the proven core for baby, kids, and retail programs. By tuning fiber denier, zone density, and—when needed—pellet pouches, you can deliver the exact hug feel your market expects. For eco or baby lines, switch to rPET and low-lint clean grades, then support the claim with proper certificates and clear care labels.

At Kinwin, my team and I help brands specify stuffing systems that feel right in the hand and pass real-world use—from sampling to mass production and compliance. If you’re building a new plush range or upgrading an existing one, email [email protected] or visit kinwintoys.com. We’ll turn your brief into a safe, consistent, and cost-smart filling plan.