Getting a perfect sample is only half the journey. The real challenge begins when production scales from one approved piece to thousands of units. Many brands have experienced this frustration: the sample looks excellent, but bulk production feels slightly different—softer, tighter, uneven, or inconsistent.

Mass production quality does not depend on luck. It depends on clear standards, disciplined systems, and structured control at every stage. When these elements are defined early, production becomes predictable and stable.

Let’s start with the foundation—quality standards before production even begins.

What Quality Standards Should Be Defined Before Mass Production Begins?

Mass production quality starts long before sewing begins. If standards are not clearly defined at the beginning, every department may interpret “acceptable quality” differently.

From my experience, most bulk quality problems are not caused by poor workmanship. They are caused by unclear standards.

Before mass production starts, brands and factories should clearly define the following:

First, dimensional tolerances.

Approved sample measurements should include allowable variation ranges. For example, ±5mm for body height or ±3% for stuffing weight. Without tolerance standards, inspectors cannot judge consistency objectively.

Second, material specifications.

Fabric codes, pile direction, thread type, embroidery thread color numbers, and filling grade must be locked and documented. Even small material substitutions can change appearance and feel.

Third, workmanship standards.

Stitch density, seam reinforcement areas, stuffing firmness levels, and embroidery clarity requirements must be specified.

Fourth, appearance criteria.

Color consistency, surface cleanliness, label placement, and packaging presentation should all have defined expectations.

Fifth, defect classification levels.

Clear definitions of critical, major, and minor defects allow inspectors to apply consistent judgment during inspection.

Here is a simple example of how standards guide production:

| Quality Element | Defined Standard | Why It Matters |

|---|---|---|

| Body height tolerance | ±5mm | Prevent size variation |

| Stuffing weight | 150g ±3% | Maintain firmness consistency |

| Stitch density | 8–10 stitches/cm | Ensure seam strength |

| Fabric code | Locked per sample | Prevent color drift |

| Embroidery placement | Within 2mm tolerance | Protect brand image |

When these standards are clearly written and shared with production teams, quality becomes measurable—not subjective.

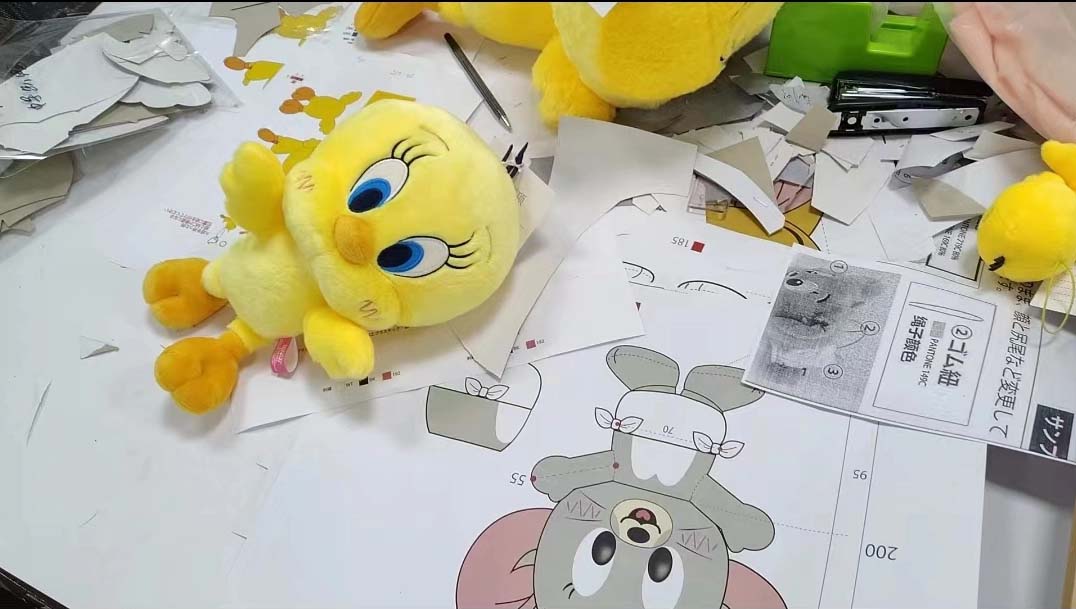

At Kinwin, once a sample is approved, we generate a production specification sheet that includes material codes, measurements, seam details, stuffing weights, and inspection points. This document aligns our cutting, sewing, stuffing, and QC teams before bulk production begins.

For buyers, asking for documented production standards is one of the best ways to evaluate whether a factory is prepared for large-scale consistency.

How Do Pre-Production Samples and PPS Approvals Prevent Bulk Errors?

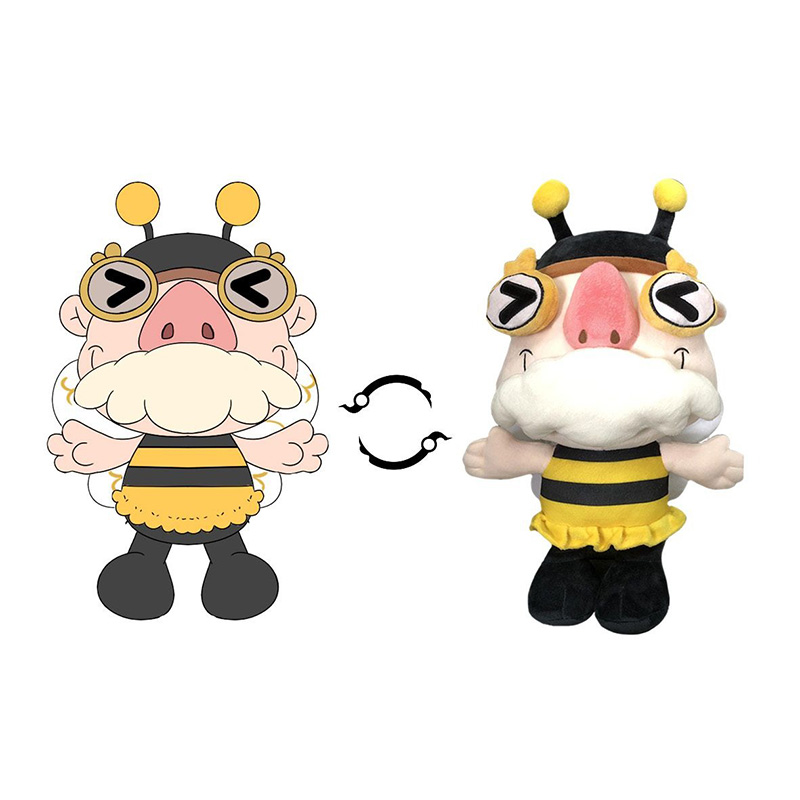

Many bulk quality issues happen because production starts based on assumptions rather than confirmation. A pre-production sample (often called PPS) exists to remove those assumptions.

A PPS is not just another sample. It is the final validation step before full mass production begins, made using actual production materials, machines, and workers.

The main purpose of a PPS is to confirm that what was approved in development can truly be reproduced under real production conditions.

Here’s how PPS approval prevents bulk errors:

First, it confirms real material usage.

Sometimes development samples are made with limited fabric or temporary substitutes. PPS must use the actual bulk fabric batch, correct thread type, final embroidery files, and real stuffing material. This prevents unexpected differences once mass production begins.

Second, it verifies production processes.

The same sewing line, operators, and machine settings used in bulk production should be used for the PPS. This ensures stitching tension, seam structure, and stuffing firmness match mass production reality.

Third, it checks labeling and packaging accuracy.

Care labels, brand tags, hangtags, barcodes, and polybag instructions are verified during PPS stage to avoid compliance or retail issues later.

Fourth, it validates measurement tolerances.

PPS allows measurement checks under production conditions to ensure tolerances defined earlier are achievable.

Fifth, it creates a locked reference sample.

Once approved, the PPS becomes the official golden reference for bulk inspection.

Here’s how PPS reduces production risk:

| PPS Function | What It Confirms | Risk Prevented |

|---|---|---|

| Material validation | Bulk fabric & filling match | Color & feel variation |

| Process verification | Real sewing & stuffing stability | Structural inconsistency |

| Label confirmation | Correct branding & compliance | Market rejection |

| Measurement check | Tolerance feasibility | Size complaints |

| Golden sample locking | Reference alignment | Production drift |

Without a proper PPS process, factories may move directly from development sample to mass production. That shortcut often leads to costly corrections, delays, and rework.

At Kinwin, we treat PPS approval as a mandatory control point. No large order moves forward until the PPS is reviewed and signed off. This simple discipline significantly reduces bulk error rates and protects delivery timelines.

For buyers placing large-volume orders, always ask:

“Will there be a pre-production sample made with real bulk materials?”

If the answer is unclear, risk increases.

How Is In-Line Quality Control Implemented During Production?

If quality control only happens at the end of production, it is already too late. By that time, thousands of units may have been completed. Fixing problems becomes expensive and time-consuming.

That is why professional plush factories rely on in-line quality control (IPQC)—continuous inspection during each stage of production.

In-line QC is not just random checking. It is a structured system with defined checkpoints.

Here’s how it works in practice:

First, material verification before cutting.

QC confirms that the fabric batch matches the approved sample in color, pile direction, thickness, and backing quality. This prevents early-stage material variation.

Second, first-piece inspection after cutting and sewing begins.

Before the sewing line runs at full speed, QC checks the first completed unit for seam placement, stitch density, alignment, and proportion accuracy.

Third, mid-line sewing inspection.

During sewing, inspectors monitor stitch tension, seam reinforcement at stress points, and symmetry. Weak seams are corrected immediately before hundreds of pieces are affected.

Fourth, stuffing weight and shaping control.

QC randomly weighs stuffed units to confirm filling tolerance. They also check shape balance—especially head roundness and sitting stability.

Fifth, embroidery and printing position verification.

Positioning guides are checked against golden samples to avoid drifting eye placement or logo misalignment.

Sixth, semi-finished random sampling.

Random partially finished toys are inspected during assembly to detect pattern distortion early.

Here’s how in-line QC protects production stability:

| Production Stage | QC Focus | Problem Prevented |

|---|---|---|

| Fabric stage | Color & batch alignment | Surface variation |

| Cutting stage | Pattern accuracy | Shape inconsistency |

| Sewing stage | Stitch density & strength | Seam failure |

| Stuffing stage | Weight & balance | Deformation |

| Decoration stage | Position & clarity | Brand errors |

| Assembly stage | Overall symmetry | Batch variation |

The key advantage of in-line QC is speed of correction.

If a stitching issue is found early, only a few pieces are affected—not the entire order.

At Kinwin, QC is embedded inside production lines rather than separate from them. Inspectors report directly to supervisors and adjustments are made immediately. This reduces defect accumulation and protects delivery schedules.

For buyers, asking about in-line QC checkpoints gives insight into how seriously a factory manages risk. A strong in-line QC system is one of the clearest signs of a professional manufacturer.

Which Key Defects Must Be Monitored in Large Plush Toy Orders?

When production volume increases, defect risk increases proportionally. In small sample quantities, small inconsistencies may not seem serious. But in bulk production, even a minor issue can affect thousands of units.

To ensure mass production quality, factories must clearly define and monitor key defect categories.

In professional plush manufacturing, defects are usually grouped into three levels: critical, major, and minor.

Here are the most important defect types that require strict monitoring:

First, structural defects.

These affect durability and safety.

Examples include:

- Open seams

- Weak stitching at stress points

- Detached accessories

- Loose eyes or parts

- Internal filling leakage

Structural defects are often classified as critical because they can lead to product failure or safety risks.

Second, dimensional and proportion defects.

These affect consistency and brand presentation.

Examples include:

- Body height outside tolerance

- Uneven arm or leg length

- Head tilt

- Sitting imbalance

When multiple pieces vary in size or posture, brand image becomes inconsistent.

Third, stuffing and firmness defects.

These affect user experience.

Examples include:

- Overstuffed units

- Underfilled bodies

- Uneven internal distribution

- Flattened shapes

Customers immediately notice differences in feel.

Fourth, fabric and surface defects.

These affect visual quality.

Examples include:

- Pile direction mismatch

- Visible stains or oil marks

- Fabric holes

- Uneven color tone

Surface defects strongly influence perceived quality.

Fifth, decoration defects.

These affect brand identity.

Examples include:

- Crooked embroidery

- Wrong thread color

- Misaligned logo

- Printing blur or fading

Here’s how defect monitoring is typically structured:

| Defect Category | Example Issue | Risk Level |

|---|---|---|

| Structural | Open seam | Critical |

| Dimensional | Size variation | Major |

| Stuffing | Uneven firmness | Major |

| Fabric | Visible stain | Major |

| Decoration | Logo misalignment | Major / Minor (depending on severity) |

Monitoring these defect types during production allows factories to stop problems early.

Professional manufacturers use:

- Defect classification standards

- Acceptable tolerance ranges

- Clear rejection criteria

- Immediate correction procedures

At Kinwin, defect categories are defined before production begins. Our QC team classifies issues clearly and corrects them at source. This prevents defect escalation and protects shipment quality.

For buyers, asking “What are your defined defect categories and tolerance standards?” is an effective way to evaluate a factory’s seriousness about quality.

How Do Final Inspections and AQL Standards Protect Shipment Quality?

Even with strong in-line control, final inspection is still a critical checkpoint before shipment. It serves as the last quality filter to confirm that the entire batch meets agreed standards.

Final inspection is not just a visual check. In professional plush manufacturing, it is a structured sampling process based on AQL (Acceptable Quality Limit) standards.

AQL determines how many units are randomly selected from a batch and how many defects are acceptable within that sample.

Here’s how final inspections typically work:

First, random sampling.

Units are selected randomly from different cartons and production times to ensure representative coverage.

Second, visual and measurement checks.

Inspectors compare sampled units against the approved golden sample and specification sheet. Measurements, shape balance, stuffing weight, and decoration alignment are verified.

Third, defect classification.

Detected defects are categorized as critical, major, or minor according to predefined criteria.

Fourth, acceptance or rejection decision.

If defect counts exceed the AQL threshold, corrective action or rework is required before shipment.

Here’s a simplified example of how AQL works:

| Inspection Level | Sample Size | Critical Defect | Major Defect | Minor Defect |

|---|---|---|---|---|

| AQL 1.0 | 80 units | 0 allowed | Limited | Limited |

| AQL 2.5 | 125 units | 0 allowed | Controlled | Controlled |

For plush toys intended for children, critical defects (such as open seams or detached parts) are typically set at zero tolerance.

Why AQL matters for buyers:

- It provides an objective acceptance standard

- It reduces subjective arguments about quality

- It protects shipment consistency

- It allows large batches to be evaluated efficiently

Without AQL-based inspection, quality decisions become inconsistent and dependent on personal judgment.

At Kinwin, final inspection is conducted according to agreed AQL levels. Reports are documented and can be shared with buyers before shipment. This transparency helps build trust and reduces post-delivery disputes.

For buyers placing bulk orders, always confirm:

- What AQL level will be applied?

- Who conducts the inspection?

- Will inspection reports be provided?

These questions reveal how seriously shipment quality is controlled.

How Can Data Tracking and Continuous Improvement Sustain Long-Term Quality?

Mass production quality is not maintained by inspection alone. It is sustained by data.

Factories that rely only on visual checks often repeat the same mistakes. But factories that record, analyze, and improve based on production data gradually reduce defect rates and increase consistency over time.

Data tracking in plush manufacturing typically includes:

First, defect rate monitoring per production batch.

Tracking how many defects appear at sewing, stuffing, or decoration stages helps identify weak points in the process.

Second, material batch performance tracking.

Recording which fabric batches show higher defect rates helps prevent future sourcing risks.

Third, rework and repair analysis.

If certain issues require repeated repair—such as seam openings or embroidery misalignment—the root cause must be addressed in pattern, process, or training.

Fourth, production time variance monitoring.

Unusual production speed fluctuations may indicate process instability or operator inconsistency.

Fifth, customer complaint feedback integration.

Returns and post-shipment feedback should be analyzed and linked back to production data for preventive action.

Here’s how continuous improvement typically works:

| Data Type | What It Reveals | Improvement Action |

|---|---|---|

| Defect rate by stage | Weak production area | Process adjustment |

| Material batch records | Fabric risk patterns | Supplier control |

| Repair frequency | Repeated weak points | Pattern reinforcement |

| Production time variance | Operator inconsistency | Training or supervision |

| Customer feedback | Market perception gap | Quality standard upgrade |

Factories committed to long-term quality improvement usually implement:

- Regular internal quality review meetings

- Operator retraining when defect patterns appear

- Process optimization after each major order

- Supplier performance evaluation

At Kinwin, quality data is reviewed after every large order. When defect patterns appear, corrective actions are implemented before the next production cycle. This continuous loop protects long-term buyer relationships.

For brands planning repeat orders or long-term partnerships, continuous improvement capability is just as important as current inspection performance.

A factory that improves over time reduces your future risk.

Conclusion

Ensuring plush toy mass production quality requires more than a good sample. It depends on clear standards, disciplined PPS approvals, structured in-line control, defect monitoring, AQL-based final inspection, and long-term data-driven improvement.

When these systems work together, bulk production becomes stable, predictable, and scalable.

If you are preparing for a large plush order and want a manufacturing partner with structured quality control systems, our team at Kinwin is ready to support your project.

Contact: [email protected]

Visit: https://kinwintoys.com