Plush Stuffed Animals Toys Manufacturer | OEM & ODM Custom Plush Factory in China

Work directly with an experienced plush stuffed animals toys manufacturer in China. You get full OEM & ODM support, stable quality control, and efficient production from sampling to bulk orders. Whether you are building a brand, expanding a product line, or sourcing for wholesale, you gain a reliable factory partner focused on quality, safety, and long-term cooperation.

Why Global Buyers Choose Our Plush Stuffed Animals Toys Manufacturing

When choosing a plush stuffed animals toys manufacturer, what matters most is reliability, consistency, and long-term value. Our factory is built to help brands and buyers reduce risk, speed up development, and scale production with confidence.

Factory-Direct OEM & ODM Capability

You work directly with the manufacturer, not a trading layer. This means clearer communication, faster feedback, better cost control, and flexible customization from concept to mass production.

High Sampling Accuracy for Brand Designs

Our experienced pattern makers and sampling team focus on structure, proportions, and details, helping your plush stuffed animals toys closely match original designs and market expectations.

Stable Quality Control from Materials to Packing

We apply strict inspections at every stage, including fabrics, fillings, sewing, stuffing, and final packing, ensuring consistent quality across samples and bulk orders.

Compliance with Global Safety Standards

We support plush stuffed animals toys for different markets with required testing standards, helping you meet safety and compliance expectations before shipment.

Scalable Production for Growing Orders

Whether you start with a trial order or scale up for wholesale and retail channels, our production system is designed to support stable lead times and repeat orders.l.

Choosing the right factory means choosing fewer problems and smoother growth. We focus on being a long-term manufacturing partner, not just a supplier.

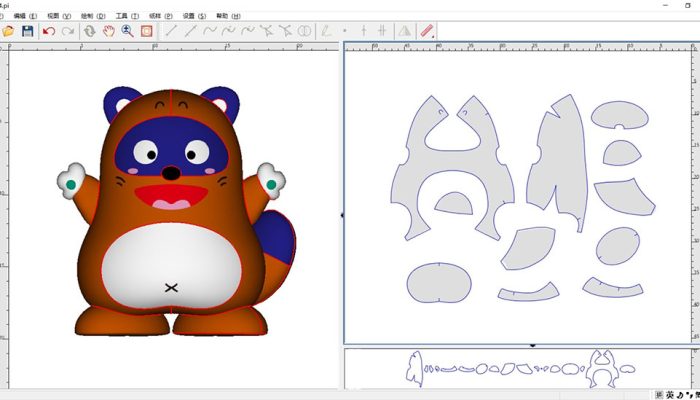

How Our Plush Manufacturing Team Achieves 95% Design Accuracy

High design accuracy is critical for brand consistency and market acceptance. Our team focuses on structure, details, and communication at every stage, ensuring your plush stuffed animals toys closely match the original concept and remain consistent from sample to bulk production.

Experienced Pattern Makers with Plush-Specific Expertise

Our pattern makers specialize in plush stuffed animals toys, understanding how fabric stretch, pile direction, and seam structure affect final shape. This allows us to translate flat artwork into accurate 3D plush forms with balanced proportions and stable structure.

Detailed Pre-Sampling Design Review Process

Before sampling, our team reviews all design files, reference images, and size requirements in detail. Potential risks are identified early, reducing revisions and ensuring the first sample already meets most visual and functional expectations.

Material Matching Based on Design Intent

We select fabrics, fillings, and accessories that best match the original design intent, including texture, softness, and visual effect. Proper material choices help achieve consistent appearance and feel between samples and bulk orders.

Cross-Team Coordination Between Design and Production

Design, sampling, and production teams work closely throughout the process. Continuous feedback ensures details are adjusted correctly before mass production, helping maintain high replication accuracy at scale.

If design accuracy matters to your brand, working with a team that understands plush manufacturing details makes a real difference.

Precision Design vs Final Product Comparison

This video compares the original design with the finished plush product side by side, allowing buyers to instantly verify accuracy. From proportions and facial expressions to embroidery placement, color matching, and overall structure, every key detail closely follows the approved design. This clear comparison demonstrates our ability to achieve 95%+ design accuracy and gives brands confidence before moving into bulk production.

Custom Plush Stuffed Animals Toys for Different Markets and Uses

Our plush stuffed animals toys cover a wide range of categories designed for different markets, age groups, and sales channels. From classic animal plush to innovative functional designs, you can source diverse products from one reliable manufacturer, reducing supplier complexity and speeding up product launches.

Animal Plush Toys

Classic animal plush toys with strong market demand, suitable for retail, gifts, and brand mascots.

Food Plush Toys

Fun and eye-catching food-themed plush toys, popular for gifts, promotions, and kids’ collections.

Plant Plush Toys

Soft plant plush designs that combine decoration and comfort, ideal for lifestyle and home markets.

Ocean Plush Toys

Sea animal plush toys designed for educational, gift, and themed collections.

Blind Box Plush Toys

Collectible blind box plush toys designed to drive repeat purchases and fan engagement.

Weighted Plush Toys

Weighted plush toys offering comfort and sensory support for kids and adults.

Interactive Plush Toys

Plush toys with sound, movement, or simple interaction features to increase play value.

Knitted Plush Toys

Handcrafted-style crochet plush toys with a unique texture and premium feel.

Plush Keychains

Small plush keychains designed for promotions, giveaways, and accessory lines.

Plush Backpacks

Functional plush backpacks combining storage with playful design, popular with kids.

Plush Pillows

Soft plush pillows designed for comfort, decoration, and daily use.

Baby Plush Toys

Baby-safe plush toys with soft fabrics and simple structures for early development.

Dinosaur Plush Toys

Dinosaur-themed plush toys that remain strong sellers in global kids’ markets.

Realistic Plush Toys

Highly detailed plush toys designed to resemble real animals with accurate shapes and colors.

Holiday Plush Toys

Seasonal plush toys designed for Christmas, Halloween, Easter, and other festivals.

Vehicle Plush Toys

Soft plush toys shaped as cars, trains, and transportation themes for creative play.

International Certifications Supporting Plush Stuffed Animals Toys Compliance

For global brands and importers, certifications are not just documents — they are proof of safety, compliance, and reliability. Our plush stuffed animals toys are produced under internationally recognized standards, helping you enter different markets with fewer risks and smoother customs clearance.

CE Certification

Our plush toys meet CE requirements for the European market, covering mechanical safety, chemical safety, and overall product compliance for children’s products.

ASTM Certification

We support ASTM F963 testing for plush stuffed animals toys exported to the United States, ensuring materials, stitching, and components meet U.S. safety regulations.

EN71 Certification

Our products can comply with EN71 Parts 1, 2, and 3, covering physical, flammability, and chemical safety for plush toys sold in Europe.

ISO Factory Audits

Our factory operates under ISO quality management systems and supports social compliance audits, giving buyers confidence in stable production and ethical manufacturing.

Choosing a certified manufacturer helps protect your brand, your customers, and your long-term market access.

Step-by-Step Export Process for Plush Stuffed Animals Toys from China

Exporting plush stuffed animals toys from China requires more than production capacity alone. A clearly defined export process helps buyers control risks, reduce delays, and ensure stable supply to their target markets. Below is a detailed explanation of each key step, designed to help brand owners, importers, and wholesale buyers understand what really matters in real export operations.

Product Specification Confirmation & Market Requirement Alignment

Before production starts, all product details must be fully confirmed, including size tolerance, fabric type, filling materials, stitching structure, labels, packaging format, and destination market requirements. This step ensures the plush stuffed animals toys are designed to meet both commercial expectations and regulatory standards. Clear confirmation at this stage helps buyers avoid misunderstandings, redesign costs, and compliance risks later in the export process, especially when selling across multiple markets.

Sampling Approval & Pre-Production Validation

A pre-production sample is produced based on confirmed specifications and design files. This sample becomes the physical benchmark for mass production. Buyers review appearance, structure, softness, stitching quality, and overall accuracy to ensure the plush stuffed animals toys match expectations. Thorough sample approval reduces the risk of bulk deviations and helps both parties align on quality standards before large-scale production begins.

Mass Production with In-Process Quality Control

Once the sample is approved, bulk production begins. Quality control is carried out at key stages such as fabric cutting, sewing, stuffing, shaping, and finishing. In-process inspections allow issues to be identified early, preventing large-scale defects. This step is critical to maintaining consistency between samples and bulk orders and ensuring stable quality across different production batches.

Safety Testing & Compliance Documentation Preparation

Based on the destination country, required safety tests such as CE, EN71, or ASTM F963 are arranged. Test reports, material declarations, and compliance documents are prepared before shipment. This step helps buyers avoid customs clearance delays, product recalls, or market access issues. Proper compliance preparation protects both the brand and the long-term sales plan.

Export Packaging, Labeling & Logistics Planning

Plush stuffed animals toys are packed according to shipping and market requirements, including carton strength, labeling language, barcodes, and packing lists. Logistics methods such as sea freight, air freight, or express shipping are selected based on cost, volume, and delivery timelines. Proper planning at this stage helps buyers balance budget control and delivery speed.

Customs Clearance & Final Delivery to Destination

Export documents such as commercial invoices, packing lists, and bills of lading are prepared for customs clearance. Once cleared, goods are shipped to the destination port and delivered to warehouses, distribution centers, or fulfillment hubs. Smooth customs handling ensures plush stuffed animals toys reach the market on time and supports reliable inventory planning for buyers.

A structured export process gives buyers better control, fewer surprises, and more confidence when sourcing plush stuffed animals toys from China.

Common Fabrics and Fillings Used in Plush Stuffed Animals Toys Manufacturing

Material selection directly affects softness, safety, appearance, and cost control. We help buyers choose the right fabric and filling combinations based on target market, age group, product positioning, and compliance requirements.

Common Plush Fabrics

Short Plush Fabric

Short plush is widely used for plush stuffed animals toys due to its smooth surface, good durability, and stable color performance.

Super Soft Fabric

Crystal plush offers a softer touch and more premium feel, often used for higher-end or gift-focused plush products.

PV Fleece Fabric

PV fleece provides a dense pile and uniform texture, suitable for plush toys that require a clean and modern appearance.

Cotton Fabric

Cotton-based fabrics are commonly used for baby plush toys, offering a more natural and skin-friendly touch.

Common Plush Accessories

PP Cotton Filling

PP cotton is the most common filling material, known for its light weight, resilience, and cost efficiency. It suits most plush doll types.

Recycled Fiber Filling

You support sustainability goals while maintaining similar softness and structure to standard fiberfill. Suitable for eco-conscious brands.

Memory Foam Filling

Memory foam is used in special plush dolls that require shape retention or support, such as pillows or functional plush products.

Weighted Filling Materials

Glass beads or weighted pellets are used to add weight for sensory or calming plush dolls.

All fabrics and fillings can be adjusted to meet safety standards and market requirements.

Fabric and Accessories Safety Standards for Plush Stuffed Animals Toys Manufacturing

Material and accessory safety is critical for plush stuffed animals toys, especially for children’s products. We apply strict safety standards from sourcing to final inspection, helping buyers reduce compliance risks and protect their brand reputation in different markets.

Non-Toxic and AZO-Free Fabric Standards

All fabrics used in plush stuffed animals toys are required to meet non-toxic and AZO-free requirements. This helps ensure color dyes and chemical residues are safe for skin contact and compliant with major international toy safety regulations.

Secure Attachment of Eyes and Decorative Accessories

Plastic eyes, noses, and decorative parts are tested for pull strength and attachment security. For baby and toddler plush toys, embroidered or stitched details are recommended to eliminate choking hazards.

Accessory Material Compliance and Traceability

All accessories such as labels, threads, zippers, and buttons are sourced from compliant suppliers and can be traced back to material records. This ensures consistent quality and easier compliance verification during audits or inspections.

Flammability and Mechanical Safety Testing

Fabrics and accessories are evaluated for flammability resistance and mechanical safety based on destination market requirements. This reduces the risk of product rejection, recalls, or customs delays.

Strict safety control over fabrics and accessories ensures plush stuffed animals toys are safe, compliant, and ready for global markets.

Flexible Customization Scope for Plush Stuffed Animals Toys Manufacturing

Our customization scope is designed to give buyers full control over product appearance, function, and positioning. Whether you are developing a new plush line or expanding an existing collection, you can customize key elements to match your market needs.

Plush Toy Style & Category Customization

We support customization across different plush categories, including animals, food, characters, seasonal themes, and functional plush toys.

Size, Shape, and Structure Customization

Toy size, proportions, internal structure, and overall shape can be adjusted based on age group, usage, and packaging requirements.

Material, Color, and Craft Customization

Fabrics, fillings, colors, embroidery, printing, and accessory details can be customized to meet design and safety requirements.

Branding and Packaging Customization

Logos, labels, hang tags, and packaging methods can be customized to align with brand identity and retail channels.

A clear customization scope helps reduce development time and avoid unnecessary revisions before mass production.

Precision Embroidery Craftsmanship

This video highlights our embroidery craftsmanship used for facial expressions, logos, and fine decorative details on plush toys. By precisely controlling stitch density, thread tension, color accuracy, and placement, we achieve clean lines and stable results that can be consistently reproduced from samples to bulk production. High-quality embroidery enhances visual appeal, durability, and brand recognition.

Popular Plush Stuffed Animals Toys Styles Across Key Global Markets

Understanding regional preferences helps brands design plush stuffed animals toys that sell faster and reduce market testing risks. Below are five key markets and the plush styles that consistently perform well, based on buyer feedback, retail trends, and long-term export experience.

United States – Character-Driven and Gift-Oriented Plush Toys

In the U.S. market, plush stuffed animals toys with strong character appeal perform especially well. This includes animals with clear personalities, expressive faces, and storytelling elements. Licensed-style designs, holiday plush toys, and large-size gift plush are popular across retail and online channels. Buyers also value softness, durability, and packaging suitability for gifting, making plush toys with emotional connection and brand storytelling more competitive.

Japan – Kawaii, Minimal, and Collectible Plush Styles

Japanese buyers strongly favor kawaii-style plush toys with simplified shapes, soft color palettes, and gentle expressions. Smaller-sized plush stuffed animals toys designed for collection, desk decoration, or blind box series are especially popular. Consistency in design details and high finishing quality are critical, as consumers expect refined craftsmanship and cohesive series concepts rather than oversized or exaggerated designs.

Europe – Natural, Eco-Friendly, and Premium Plush Designs

European markets often favor plush stuffed animals toys with a natural look and premium feel. Animal designs inspired by wildlife, farm animals, or realistic proportions perform well, especially when paired with eco-friendly materials. Neutral colors, clean stitching, and compliance with sustainability expectations increase acceptance among retailers and parents. Plush toys positioned as long-lasting companions rather than disposable toys tend to sell better.

Middle East – Large, Decorative, and Luxury Plush Toys

In Middle Eastern markets, larger plush stuffed animals toys with bold designs and decorative value are often preferred. Oversized plush toys, rich colors, and premium fabrics attract attention in gift shops and malls. Plush toys are frequently purchased as gifts, so visual impact, fullness, and perceived value are important factors. Durable stitching and high-quality finishing help support higher price positioning.

South Korea – Trend-Driven and Lifestyle Plush Products

South Korean buyers favor plush stuffed animals toys that align with lifestyle trends, social media aesthetics, and pop culture. Soft textures, pastel colors, and multifunctional designs such as plush cushions or wearable plush accessories perform well. Plush toys are often positioned as lifestyle items rather than children’s toys, making design relevance and visual appeal key drivers of purchase decisions.

Choosing the right plush style for each market helps brands shorten launch cycles and improve sales performance.

Plush Stuffed Animals Toys Manufacturing Process from Design to Delivery

A clear and controlled production process helps reduce errors, maintain quality consistency, and deliver on time. Our plush stuffed animals toys production flow is designed to support stable output from sampling to bulk orders.

Design Review & Material Confirmation

We review design files and confirm fabrics, fillings, colors, and construction details to ensure all specifications are clear before production starts.

Pattern Making & Fabric Cutting

Patterns are created based on approved designs, followed by precise fabric cutting to ensure accurate shapes and size consistency.

Sewing & Assembly

Cut pieces are sewn and assembled by experienced workers, focusing on stitch strength and overall structure.

Stuffing & Shaping

Plush toys are filled and shaped to achieve balanced softness and stable form.

In-Process Quality Inspection

Quality checks are performed during key stages to identify issues early and maintain consistency.

Final Inspection & Packing

Finished products undergo final inspection before packing according to shipping and market requirements.

A standardized production process helps ensure reliable quality and smooth order execution.

Precision Plush Production Workflow

This video presents the complete plush toy production workflow inside our factory, from material preparation and cutting to sewing, stuffing, quality inspection, and final packing. Every step follows standardized operating procedures to ensure stable quality, efficient execution, and consistent results from approved samples to bulk production. This clear workflow gives brands confidence in quality control, capacity, and on-time delivery.

Strict Quality Control System for Plush Stuffed Animals Toys Manufacturing

A strict quality control system is essential to ensure plush stuffed animals toys remain consistent, safe, and reliable from sampling to mass production. Our quality management focuses on prevention, process control, and final verification, helping buyers reduce defects, avoid delays, and protect brand reputation in global markets.

Incoming Material Inspection (IQC)

All fabrics, fillings, and accessories are inspected before entering production. We check material specifications, color consistency, hand feel, and basic safety compliance to ensure they match approved standards. Early material inspection helps prevent quality deviations at the source and avoids production delays caused by unqualified raw materials.

Pattern and Cutting Accuracy Control

Before sewing begins, patterns and cutting results are carefully checked for size accuracy and shape consistency. This step ensures each plush stuffed animals toys piece follows the approved design proportions, reducing assembly issues and minimizing size variation in bulk production.

In-Process Quality Control During Sewing

During sewing and assembly, quality checks focus on stitch strength, seam alignment, and overall structure stability. Continuous inspection during this stage helps identify issues early and prevents large-scale defects from spreading through the production line.

Stuffing and Shape Consistency Inspection

Stuffing density and shaping are inspected to ensure plush toys maintain balanced softness and consistent appearance. Uneven filling or distorted shapes are corrected before moving to the next stage, helping maintain uniform quality across all units.

Final Quality Inspection Before Packing (FQC)

Finished plush stuffed animals toys undergo final inspection, including appearance, stitching, cleanliness, labeling, and packaging readiness. This step ensures only qualified products proceed to packing and shipment.

Random Sampling and Pre-Shipment Checks

Before shipment, random sampling inspections are conducted to verify consistency across the entire order. Pre-shipment checks help buyers gain confidence that bulk goods match approved samples and agreed specifications.

A structured quality control system helps ensure stable quality, fewer claims, and smoother long-term cooperation.

Trusted by Leading Global Brands

Strong partnerships prove strong capabilities. Over the years, Kinwin has worked with world-leading brands and retailers to deliver interactive plush toys that meet the highest standards of creativity, safety, and quality. By choosing us, you gain a supplier that is trusted by top companies worldwide—and the same reliability is available to your brand.

Customer-First Approach in Plush Stuffed Animals Toys Manufacturing

Choosing the right soft toy manufacturer directly affects your product quality, cost control, and delivery reliability. Wholesale buyers work with us not just for production, but for long-term stability, clear communication, and predictable results.

Clear Communication from the Start

We focus on clear and timely communication from the first inquiry, helping buyers define requirements and avoid misunderstandings.

Professional Guidance at Every Stage

Our team provides practical advice during design, sampling, production, and export, helping buyers make informed decisions.

Transparent Cost and Timeline Management

We provide clear cost structures and realistic timelines, helping buyers plan budgets and launches with confidence.

Flexible Support for Different Project Sizes

Whether small trial orders or large-scale production, we adapt our support to match project needs.

Ready to Start Your Plush Stuffed Animals Toys Project?

Choosing the right plush stuffed animals toys manufacturer can directly impact your product quality, delivery timeline, and brand reputation. Whether you are developing a new plush line, expanding an existing collection, or sourcing for wholesale and retail channels, working with a factory that understands design accuracy, safety standards, and export requirements makes the process smoother and more predictable.

Our team is ready to support you from early concept discussion to sampling, production, and shipment. You get clear communication, practical advice, and factory-level execution tailored to your market needs. By sharing your project details early, we can help you avoid common mistakes, shorten development time, and move forward with confidence.

If you are comparing suppliers, planning a new launch, or need a reliable long-term manufacturing partner, this is the right time to talk. Send us your ideas, references, or requirements, and let’s explore the most suitable solution together.

Explore Our Custom Plush Toy Series

We offer a wide selection of plush toys to meet different business needs. From baby-safe stuffed animals to collectible plush dolls, our product lines are designed for global brands, retailers, e-commerce, and promotional projects.

Frequently Asked Questions

1. What information should I send for a plush stuffed animals toys inquiry?

To quote and evaluate feasibility quickly, share: target market (US/EU, etc.), size, quantity, design files (AI/PDF/PSD) or clear images, preferred fabric and filling (or your positioning), logo/branding needs, packaging requirements, and any compliance targets (ASTM F963, EN71, etc.). If you only have a concept, send reference photos and a brief description—we can guide you step by step.

2. Can you make plush toys from a sketch or simple picture?

Yes. We support customization from sketches, reference images, or physical samples. For best accuracy, we confirm key points such as proportions, facial expression, embroidery areas, seam lines, and color references. We may suggest structural adjustments to ensure the design is manufacturable and consistent in bulk production.

3. What is the typical MOQ for plush stuffed animals toys?

Our standard MOQ is 500 pieces. For orders below this quantity, please consult with our project manager. We may offer flexible solutions depending on the product size, complexity, and customization requirements.

4. How long does sampling and bulk production usually take?

Sampling time depends on design complexity and revision rounds. Bulk production lead time depends on quantity, materials, and seasonality. For urgent timelines, we can propose ways to reduce risk, such as confirming materials early, simplifying certain details, or prioritizing key processes. Share your target deadline and we will advise a realistic production and shipping plan.

5. What safety standards can you support for different markets?

We support common toy safety standards based on your destination market, such as ASTM F963 (U.S.) and EN71 (Europe). We also pay attention to material safety (AZO-free dyes, non-toxic materials), mechanical safety (secure stitching and attachment), and labeling/packaging compliance. Requirements vary by product age grade and sales channel, so we confirm this early during inquiry.

6. Can you do embroidered eyes and details instead of plastic parts?

Yes, embroidered facial details are very common, especially for baby and toddler plush toys. Embroidery helps reduce choking risks and improves wash durability. We can match embroidery color, stitch density, and expression style based on your design, and recommend the best approach depending on fabric texture and product positioning.

7. How do you ensure consistent quality between sample and bulk orders?

We lock key specifications after sample approval, including fabric batch standards, color references, embroidery files, pattern templates, and packing methods. During production, we use in-process checks at cutting, sewing, stuffing, and finishing stages, and conduct final inspections before packing. This system helps reduce deviation and ensures bulk goods match the approved sample standard.

8. What packaging options do you offer for plush stuffed animals toys?

We can support common packaging such as individual OPP/poly bags, hang tags, color labels, barcode stickers, and carton marking. For retail or e-commerce, we can also follow specific packing instructions, including set packing, inner box options, and protective packaging for long-distance shipping. Tell us your sales channel and we’ll recommend a suitable packaging plan.

9. Can you help with color matching and material selection?

Yes. We can match colors based on Pantone references or physical samples, and recommend fabrics and fillings based on your target market, softness level, and budget. We also consider compliance needs, wash durability, and the final visual effect under different pile fabrics. Proper material selection reduces revision time and improves product consistency in bulk.

10. What is the best way to start if I’m comparing multiple manufacturers?

Start with one clear design and a short requirement list, then compare response quality, technical advice, clarity of quotation, and understanding of compliance. Ask how they control materials, stitching strength, and pre-shipment checks. A reliable plush stuffed animals toys manufacturer will proactively highlight risks and offer solutions, not only promise low prices.

If You Can lmagine lt,We Will Create lt!

1.Tell Us What You Need

Tell us as specific as possible of your needs and share your idea.

2.Get Solution & Quote

We will work on the best solution according to yourrequirements,the specific quote will be provided within 24 hours.

3.Approve for Mass Production

We will start mass production after getting your approval.