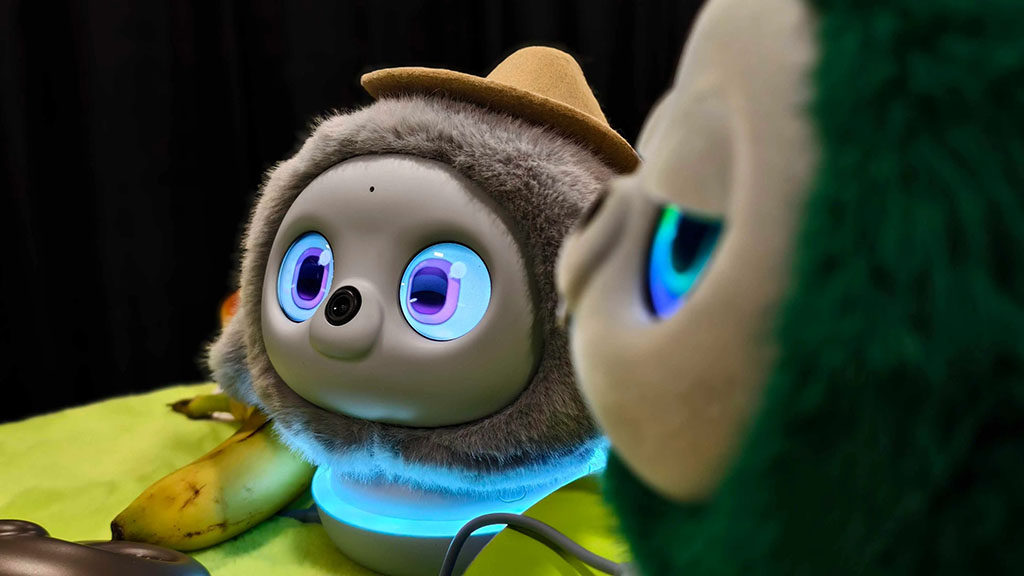

Smart plush toys represent the convergence of soft toy design and embedded technology. Unlike traditional electronic toys, smart plush must hide complex systems—sensors, audio modules, control boards, and motion components—inside a soft, squeezable structure while remaining safe, durable, and emotionally friendly. For brands, the challenge is not adding technology itself, but integrating multiple systems in a way that feels natural, reliable, and scalable for real-world production and long-term use.

What Types of Sensors Are Integrated into Smart Plush Toys?

Sensors are the foundation of smart plush interaction. They allow the plush toy to perceive touch, pressure, movement, and sometimes environmental changes. In smart plush products, sensors are selected not for maximum precision, but for stability, safety, and interpretability within a soft environment.

The most common sensor is the touch or pressure sensor, often placed in hands, feet, head, or belly. These sensors detect squeezing, tapping, or hugging actions. Because plush toys deform when touched, sensors must tolerate shape change without false triggers. Capacitive and resistive sensors are often preferred over rigid mechanical switches.

Motion-related sensors such as accelerometers or tilt sensors help the plush understand orientation changes—being lifted, shaken, or laid down. Some smart plush toys also use light or proximity sensors to detect presence, but these are less common due to higher power consumption and limited benefit in soft toys.

For brands, sensor choice directly affects interaction quality and cost. Overloading a plush with sensors increases failure points. Successful smart plush products usually rely on a small number of well-placed sensors, mapped clearly to specific interactions.

| Sensor Type | Function in Plush | Placement Consideration | Design Trade-Off |

|---|---|---|---|

| Touch / pressure | Detect squeeze or hug | Soft zones (belly, hands) | Must avoid false triggers |

| Capacitive touch | Gentle interaction | Outer fabric layers | Sensitive to humidity |

| Accelerometer | Detect movement/orientation | Core structure | Adds cost, power use |

| Tilt sensor | Simple motion detection | Central module | Lower precision |

| Proximity/light | Detect presence | External-facing | Limited plush use |

How Voice Recognition and Audio Modules Enable Interactive Communication

Voice interaction is what makes smart plush feel “alive.” Audio systems typically include a microphone, speaker, and processing module. In most smart plush toys, voice recognition is not full AI conversation, but keyword or command-based recognition designed to work reliably in noisy home environments.

Microphone placement is critical. Plush fabric muffles sound, so microphones must be positioned near thinner fabric areas or supported by internal sound channels. At the same time, placement must avoid direct access by children for safety reasons.

Audio output focuses on warmth rather than volume. Speakers are tuned for soft, friendly sound rather than sharp clarity. Many brands deliberately limit voice complexity to maintain emotional comfort and avoid privacy concerns.

From a B2B perspective, voice systems must balance responsiveness and battery life. Always-on listening increases power consumption and raises compliance concerns in some markets. As a result, many smart plush designs use touch-activated listening modes instead of continuous voice detection.

| Audio Component | Role in Interaction | Key Design Constraint | Brand Consideration |

|---|---|---|---|

| Microphone | Capture voice commands | Fabric sound absorption | Placement precision |

| Speaker | Output responses | Soft sound tuning | Emotional tone |

| Voice module | Command recognition | Limited vocabulary | Reliability > complexity |

| Activation logic | Trigger listening | Power management | Privacy compliance |

How Motion Sensors and Actuators Create Responsive Plush Movements

Motion gives smart plush toys physical feedback, which strengthens emotional connection. Movement in plush toys is typically subtle: head tilts, arm lifts, gentle vibration, or small body shifts. Large or fast movements are avoided because they conflict with the soft, comforting nature of plush.

Actuators such as micro motors or vibration units must be carefully isolated. Direct contact with stuffing can cause noise, friction, and wear. Internal housings are often used to stabilize components while allowing safe movement.

Motion sensors work together with actuators. For example, when a plush is lifted, it may respond with sound or vibration. This sensor–action loop must feel immediate but not erratic. Over-responsive motion can feel mechanical and break emotional immersion.

For brands, motion features significantly affect BOM cost and failure rate. Many successful smart plush products limit motion to one or two reliable actions rather than attempting full articulation.

| Motion Element | Function | Design Challenge | Production Impact |

|---|---|---|---|

| Vibration motor | Tactile feedback | Noise isolation | Moderate cost |

| Micro motor | Simple movement | Wear over time | Higher QC need |

| Motion sensor | Detect handling | False positives | Calibration required |

| Housing structure | Protect components | Maintain softness | Engineering complexity |

How Hardware and Software Systems Are Integrated Inside Soft Plush Structures

Integrating electronics into plush is fundamentally different from hard toys. Plush toys compress, twist, and flex. Hardware must be protected without making the toy feel rigid or uncomfortable.

Most smart plush designs use a central control module placed in the torso, surrounded by structured foam or internal casing. Sensors and actuators connect to this module via flexible wiring designed to tolerate movement. Software logic is simplified to reduce processing load and failure risk.

Software and hardware must be co-designed. Software defines how many interactions are possible, which directly influences hardware requirements. For example, fewer interaction states reduce memory needs and simplify testing.

From a manufacturing standpoint, modular design is critical. Being able to remove or replace the electronic module simplifies testing, repair, and compliance checks. Brands that ignore modularity often face higher defect rates in mass production.

| Integration Area | Common Approach | Why It Matters | Risk if Ignored |

|---|---|---|---|

| Control unit | Centralized module | Simplifies wiring | Hard to repair |

| Wiring | Flexible, reinforced | Tolerates movement | Breakage risk |

| Software logic | State-based systems | Stability | Over-complex bugs |

| Modularity | Removable electronics | Easier QC | Higher defect loss |

How Safety, Power Management, and Durability Are Ensured in Smart Plush Design

Safety is non-negotiable in smart plush toys. Electronic components introduce risks related to heat, power, and accessibility. Batteries must be securely enclosed, insulated, and tested under compression and drop conditions.

Power management focuses on low-energy operation. Smart plush toys often use sleep modes, touch-activated wake-up, or timed shutdowns. Rechargeable batteries are increasingly preferred, but charging ports must be child-safe and durable.

Durability testing is more complex than for standard plush. Smart plush must survive repeated squeezing, dropping, and sometimes washing (with electronics removed). Brands must plan for this at the design stage, not after sampling.

| Safety Aspect | Design Solution | Compliance Impact | Brand Risk |

|---|---|---|---|

| Battery safety | Sealed compartments | CPSIA / EN71 | Recall risk |

| Heat control | Low-power components | User safety | Trust damage |

| Access prevention | Hidden closures | Child safety | Regulatory failure |

| Mechanical durability | Reinforced housing | Longevity | High returns |

How Brands Balance Interactivity, Cost, and User Experience in Smart Plush Products

The biggest strategic decision in smart plush development is deciding how smart is smart enough. Every added feature increases cost, complexity, and failure risk. Successful brands define a clear interaction goal and design technology around that goal—not the other way around.

Many brands choose emotion-first interaction over technical sophistication. A plush that responds warmly to touch with sound or gentle motion often performs better than one with complex but unreliable features. Cost control also improves when interaction scenarios are limited and repeatable.

From a B2B OEM perspective, balance comes from early alignment. Brands that define target price, age group, and interaction depth early avoid costly redesigns later. OEM partners play a key role in advising which features are scalable and which should be avoided.

| Decision Factor | Strategic Focus | Best Practice | Common Mistake |

|---|---|---|---|

| Interactivity | Emotional response | Simple, clear actions | Feature overload |

| Cost control | BOM discipline | Modular electronics | Late redesign |

| User experience | Reliability | Predictable behavior | Inconsistent response |

| Scalability | Production-ready design | OEM consultation | Prototype-only thinking |

Conclusion

Smart plush toys succeed when technology enhances softness rather than competing with it. By carefully integrating sensors, voice, and motion within safe and scalable designs, brands can create emotionally engaging products that feel natural, reliable, and commercially viable in global markets.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com