Before any plush toy shipment leaves the factory, testing reports are not optional paperwork—they are risk-control tools. From my experience working with U.S. and European buyers, many compliance problems do not come from missing tests, but from requesting the wrong reports, at the wrong time, or reviewing them incorrectly.

A shipment can be delayed, rejected, or recalled even when testing exists—if reports are incomplete, outdated, mismatched to the product, or issued by non-accepted labs. This article explains exactly which testing reports buyers should request before shipment, how to interpret them, and how to use them to protect both market access and brand reputation.

What Safety Testing Reports Are Mandatory for Plush Toys in Your Target Market?

Safety testing requirements vary by market, but plush toys share a common risk profile: they are children’s products made from mixed materials. Buyers must first determine which regulations apply in their target market, then confirm that the testing scope matches those rules exactly.

For example, the U.S. market requires CPSIA-related testing, while Europe focuses on EN71 standards. Japan, South Korea, and the Middle East also have their own frameworks. A frequent mistake is accepting a single “general test report” instead of market-specific compliance evidence.

Buyers should always request market-aligned safety test reports, issued by accredited third-party labs, covering both chemical and physical risks.

| Target Market | Mandatory Safety Standard | Buyer Must Request |

|---|---|---|

| United States | CPSIA / ASTM F963 | CPSIA test report + CPC |

| European Union | EN71 Parts 1–3 | EN71 full set |

| United Kingdom | UKCA / EN71 | UKCA-aligned EN71 |

| Japan | ST Standard | ST safety reports |

| Middle East | Local GSO / SASO | Approved lab reports |

How Do Chemical Test Reports Verify Compliance with Restricted Substances Regulations?

Chemical testing reports confirm that plush toy materials comply with restricted substance regulations, which are among the most common causes of shipment rejection. These reports focus on substances such as lead, phthalates, heavy metals, azo dyes, and other harmful chemicals.

Chemical compliance is component-based, not product-based. Fabrics, inks, accessories, stuffing, and even labels may require testing. Buyers should ensure that chemical test reports clearly list tested materials, test methods, and pass/fail limits.

Another key risk is outdated testing. Chemical regulations evolve, and reports must align with current regulatory thresholds at the time of shipment.

| Chemical Risk Area | Typical Regulation | Buyer Review Focus |

|---|---|---|

| Lead content | CPSIA / EN71-3 | ppm limits met |

| Phthalates | CPSIA / REACH | Plastic components |

| Azo dyes | REACH | Fabric & prints |

| Heavy metals | EN71-3 | Migration results |

| Restricted chemicals | OEKO-TEX / REACH | Scope completeness |

What Mechanical and Physical Test Reports Confirm Product Durability and Safety?

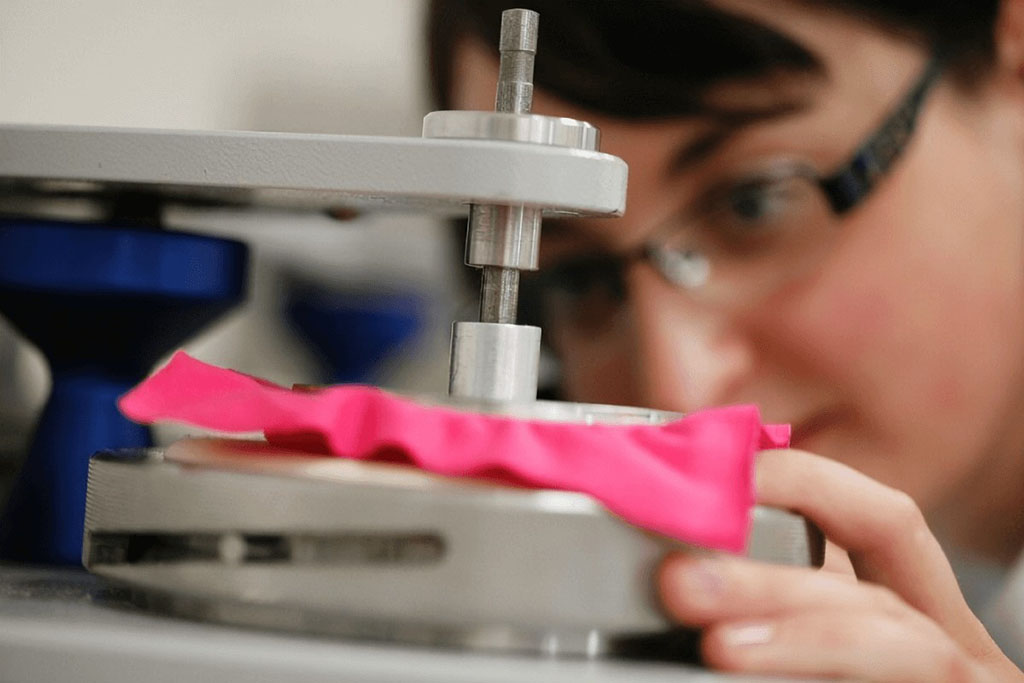

Mechanical and physical test reports verify that plush toys can withstand normal use without creating hazards such as choking, tearing, or exposure of internal components. These tests are especially critical for plush toys with eyes, noses, seams, or decorative elements.

Reports typically include seam strength, tensile testing, torque and pull tests, and drop or compression tests. Buyers should confirm that the tests were performed on production-equivalent samples, not early prototypes.

Mechanical test failures often occur due to poor design decisions or cost-driven material substitutions late in production—making pre-shipment verification essential.

| Test Type | Risk Addressed | Buyer Must Confirm |

|---|---|---|

| Seam strength | Stuffing exposure | Pass threshold met |

| Pull & torque | Detachable parts | All components tested |

| Tension test | Limb durability | Production sample used |

| Abuse simulation | Child handling | Correct age grading |

| Internal access | Hidden hazards | No exposure risk |

How Do Flammability and Material Performance Reports Affect Shipment Approval?

Flammability testing is often overlooked until shipment is blocked. Plush toys are textile products, and many markets require confirmation that materials meet flammability performance standards, especially for children’s items.

In the U.S., flammability requirements may apply depending on product category and material composition. Other markets require fabric performance testing related to heat exposure, fiber composition, and burn behavior.

Buyers should verify whether flammability testing is mandatory for their product and market, and ensure reports clearly reference tested fabrics and conditions.

| Performance Area | Applicable Market | Buyer Verification Point |

|---|---|---|

| Fabric flammability | U.S. / EU | Test method clarity |

| Fiber composition | Multiple markets | Matches BOM |

| Heat resistance | Special plush items | Performance limits |

| Label alignment | All markets | Consistent claims |

| Report validity | Global | Accredited lab only |

What Documentation Should Accompany Third-Party Lab Test Reports Before Export?

Test reports alone are not sufficient for export. Buyers should request a complete documentation package that links testing results to the shipped product. Missing or mismatched documents are a major cause of customs delays and platform rejections.

Key documents often include Children’s Product Certificates (CPC), Declarations of Conformity, material declarations, and test summaries. All documents must reference the same product identifiers, SKUs, and lab reports.

Consistency across documents is as important as the test results themselves.

| Required Document | Purpose | Buyer Check |

|---|---|---|

| Test reports | Proof of compliance | Correct scope |

| CPC / DoC | Legal declaration | Accurate references |

| Material declaration | Traceability | Matches BOM |

| Lab accreditation | Validity | Current approval |

| Shipment linkage | Customs clarity | SKU & batch match |

How Can Buyers Review and Validate Test Reports to Avoid Compliance Risks?

Many buyers receive test reports but do not actively review them. This is a major risk. A proper review process checks five critical elements: lab accreditation, test scope, sample description, regulation version, and validity period.

Buyers should confirm that the lab is accredited and accepted in the target market, that the tested sample matches the shipped product, and that the report is current. Any inconsistency should be resolved before shipment, not after arrival.

Establishing a simple internal checklist for report validation can prevent costly mistakes.

| Review Step | Risk If Missed | Buyer Action |

|---|---|---|

| Lab verification | Invalid testing | Check accreditation |

| Sample match | False compliance | Compare photos & BOM |

| Regulation version | Outdated limits | Confirm current rules |

| Report date | Expired results | Re-test if needed |

| Document alignment | Customs issues | Cross-check all files |

Conclusion

Requesting the right testing reports before shipment protects buyers from delays, recalls, and compliance failures. Clear verification ensures smoother customs clearance and safer market entry.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com