When people say “plush,” they often just mean “soft and luxurious.” But in the toy world, “plush” has a more specific meaning. It connects material, construction, and even emotion.

In modern toy terminology, “plush” describes both a type of fabric and a type of soft toy made from that fabric. Plush toys use pile fabrics with a soft, fuzzy surface and are filled with fiber or other stuffing. They are designed to feel comforting, look friendly, and keep their shape after many hugs. Today, “plush” also carries a lifestyle meaning: cozy, premium, and emotionally warm—especially in baby and kids’ products.

In this guide, I will share how we, as a plush manufacturer at Kinwin, understand and use the word “plush” when we design and produce toys for global buyers.

What does “plush” mean in modern toy terminology?

In daily speech, people use “plush” to describe something soft or high-end. In the toy industry, the word is more precise. It usually refers to soft toys made from pile fabrics (like velboa, minky, or long-pile faux fur), filled with fiber and designed primarily for hugging and comfort.

When buyers talk to my team and say “we need a plush line,” they normally mean a collection of stuffed animals or character toys using plush fabric, not just any soft material. “Plush” in this context includes feel, appearance, and emotional function. It is about softness, but also about personality, safety, and how the toy fits into a brand story.

(Image suggestion: several plush animals in different pile lengths arranged on a soft neutral background.)

How the meaning of “plush” breaks down in practice

You can think of “plush” in three linked layers:

Table 1 – Layers of meaning behind the word “plush”

| Layer | What It Refers To | Example in Toy Context |

|---|---|---|

| Material | Pile fabric with soft, raised surface | Short minky plush used for baby toys |

| Product category | Stuffed toys made from plush fabric | Teddy bears, character plush, plush dolls |

| Emotional feel | Cozy, comforting, sometimes premium or “luxury” | “Plush comforter” for infants |

When a retailer lists a product as a “plush toy,” they expect all three: the right fabric, a soft stuffed form, and a comforting feeling. This is why, as a manufacturer, we pay attention not just to softness but also to the design language, facial expressions, and how the toy feels in real hands.

“Plush” is no longer only a technical word. It has become a promise of comfort and emotional connection—especially in children’s products and gift categories.

How do materials and fabric structures define plush characteristics?

The core of “plush” is fabric. The structure, fiber type, and pile length of the fabric decide how the toy feels, how it looks under light, and how well it lasts. Two toys can share the same shape but feel completely different because of fabric choice.

In our factory work, we look at fiber (polyester, cotton blends, recycled), pile height (short, medium, long), and base knit structure. These elements define key plush characteristics: softness, shine, stretch, durability, and safety (such as shedding behavior). Different combinations support different product goals: infant-safe comforters, premium collectibles, or mass-market promotional plush.

(Image suggestion: fabric swatch board showing short plush, minky, velboa, and long-pile faux fur.)

Common plush fabrics and what they feel like

Here is a simple view of widely used plush fabrics and their typical feeling:

Table 2 – Plush fabric types and key characteristics

| Fabric Type | Typical Pile Length | Key Feel & Look | Common Usage |

|---|---|---|---|

| Short plush | 1–3 mm | Smooth, neat, low-lint | Infant toys, cushions, mascots |

| Minky / coral fleece | 2–4 mm | Very soft, slightly stretchy, matte-satin | Baby blankets, baby plush, pillows |

| Velboa | 1–2 mm | Short, dense, good print clarity | Printed characters, branded mascots |

| Long plush / faux fur | 10+ mm | Fluffy, high-volume, “furry” | Bears, fantasy animals, home decor |

| Fleece (non-pile) | N/A | Soft but without clear pile direction | Simple soft toys, blankets, apparel trims |

How structure and fiber choice shape performance

Fabric structure influences:

- Softness and drape – how the toy falls and bends.

- Durability – resistance to pilling and wear.

- Print behavior – how clearly patterns and logos appear.

For example, velboa has a tight, short pile, so printed logos or detailed patterns look sharp. Minky has a beautiful soft hand feel, but very detailed small prints may appear softer or slightly blurred.

Fiber type also matters. Most plush toys use polyester because it is durable, colorfast, and easier to keep clean. Recycled polyester offers similar performance with an eco story that many brands now want. Cotton blends can feel natural but may shrink more and show wear faster.

When we plan a plush line, we start from the desired market positioning and use case. A baby comforter might use super-soft short minky with gentle color and tight control on shedding. A premium collector piece might use long-pile faux fur for a dramatic look and luxurious hand feel. In each case, material and structure turn the abstract word “plush” into a specific customer experience.

How does plush quality vary across different manufacturing techniques?

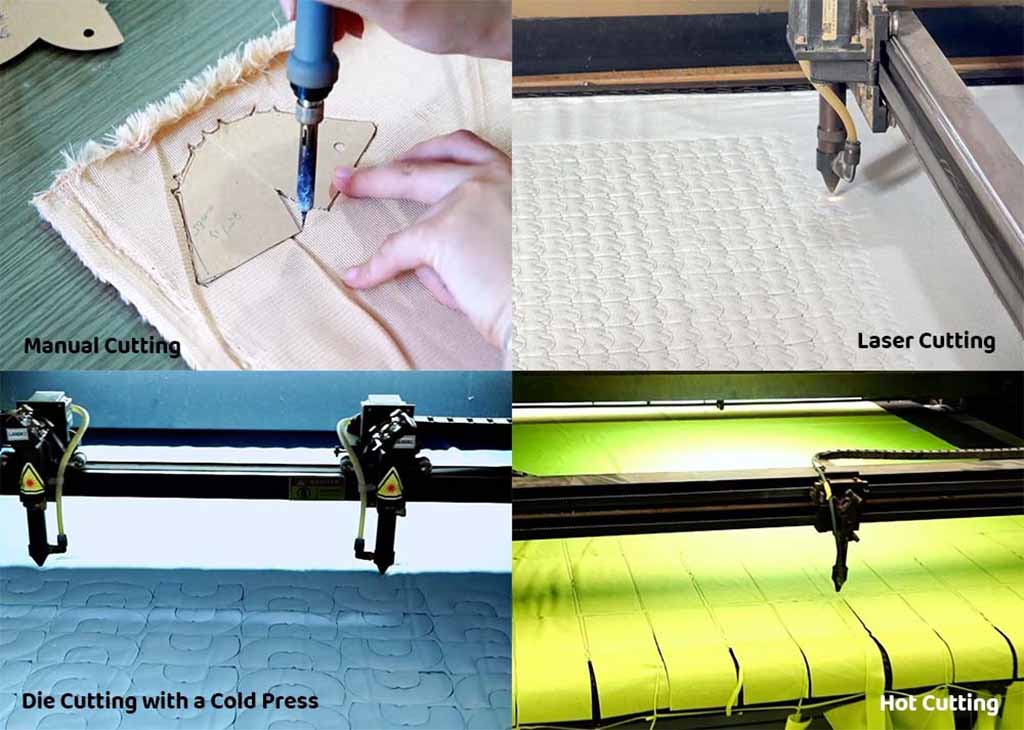

“Plush” is not only about fabric; it is also about how the toy is made. The same material can feel cheap or premium depending on cutting, sewing, stuffing, and finishing techniques. This is where manufacturing experience makes a big difference.

In our production lines, we see many quality drivers: pattern design, cutting accuracy, seam allowance control, stitching type, stuffing density, and how details like eyes and noses are attached. Better techniques create smoother shapes, stable seams, and safer, more durable toys. Lower-level techniques may still look okay in photos, but real users feel the difference quickly.

(Image suggestion: comparison of a high-quality plush seam versus a poorly aligned seam.)

Manufacturing methods and their impact on plush quality

You can think about quality differences in terms of key steps:

Table 3 – Manufacturing techniques and their effect on plush quality

| Process Area | Higher-Quality Approach | Lower-Quality Risk |

|---|---|---|

| Pattern cutting | Precise templates, consistent direction | Off-grain cutting, mismatched fabric direction |

| Sewing | Tight, even stitches, reinforced points | Loose stitches, skipped reinforcement |

| Stuffing | Layered filling, controlled density | Random stuffing, lumps, hollow areas |

| Detail attachment | Secure embroidery or locked fasteners | Weakly fixed parts that may detach |

| Finishing & QC | Trimming threads, shape adjustment, checks | Untrimmed threads, uneven shapes, minimal checks |

Why technique changes how “plush” feels and performs

Customers often say, “This plush just feels more expensive.” That feeling usually comes from:

- Smooth, symmetrical shape with no strange angles.

- Even stuffing that supports the design line.

- Seams that you can touch without feeling hard ridges or gaps.

From a brand point of view, this is crucial. “Plush” is a comfort product. If the toy feels cheap, it reduces trust in your entire range.

At Kinwin, we use a mix of machine sewing and hand finishing. Critical areas like facial curves, unusual shapes, or closing seams often need experienced handwork. We also perform needle detection and tensile tests as part of QC, which is important for markets like the USA and Europe.

When you talk with a manufacturer about plush, it helps to ask not only about materials but also about processes. How do they control stuffing density? How do they manage complex shapes? That is where the real quality differences appear.

What factors distinguish plush toys from other soft toy categories?

“Soft toy” is a broad term. Plush toys are one sub-category within it. Understanding the differences helps you plan your assortment and explain your products clearly to buyers and end consumers.

Plush toys are typically stuffed figures made from pile fabrics. Other soft toys might be made from flat fabrics (like cotton or fleece), foam, or even knitted yarn. While all of them are soft, they deliver different experiences and serve different roles. For example, a plush bear, a fabric cloth book, and a knitted doll all sit in the soft toy world, but each has its own feel, structure, and care needs.

(Image suggestion: a plush bear, a flat cloth book, and a knitted doll placed side by side.)

Plush toys versus other soft toy types

Below is a simple comparison:

Table 4 – Plush toys compared to other soft toy categories

| Category | Main Material & Construction | Typical Feel & Use |

|---|---|---|

| Plush toys | Pile fabrics + stuffing | Huggable, fluffy, emotional comfort |

| Fabric soft toys | Woven/knit fabrics, less pile | Soft but flatter; often educational or themed |

| Knitted / crocheted toys | Yarn-based | Textured, hand-made charm, niche appeal |

| Foam-based toys | Foam cores, sometimes fabric-covered | Soft but more structured (blocks, shapes) |

| Cloth books / panels | Flat textile layers with fillings | Sensory, educational, less “cuddly” |

What makes plush toys special in the soft toy universe

Plush toys stand out through:

- Strong emotional role – often “best friend” toys for children.

- Shape flexibility – able to represent animals, characters, food, transport, and more.

- Brand storytelling – easy to integrate mascots, logos, and IP characters.

Because plush toys blend softness, 3D form, and expressive faces, they are powerful branding tools. This is why many companies—not only toy brands—develop custom plush mascots for events, loyalty programs, or marketing campaigns.

At Kinwin, a large part of our OEM & ODM work is turning logos and 2D characters into plush forms. When clients say “we want a plush version,” they are asking for both a soft toy and a tangible symbol of their brand personality.

How is plush used across industries beyond toy production?

Today, “plush” goes far beyond classic teddy bears. Many industries use plush materials and plush products to add comfort, style, and emotional value to their offers. The word itself has expanded with these uses.

You see plush in home decor, pet products, travel accessories, fashion, and even promotional items. In each case, plush materials bring a certain message: cozy, friendly, and slightly indulgent. Because we are a toy-focused factory, we often support brand owners who want to extend their plush character into these new categories.

(Image suggestion: collage of a plush cushion, plush pet bed, plush keychain, and plush travel pillow.)

Cross-industry uses of plush

Here is a quick map of where plush shows up outside classic toys:

Table 5 – Plush applications beyond traditional toy lines

| Industry / Category | Plush Product Examples | Role of “Plush” in the Product Experience |

|---|---|---|

| Home & decor | Cushions, throws, plush blankets | Comfort, warmth, cozy interior styling |

| Travel & lifestyle | Neck pillows, eye masks, slippers | Soft support, relaxation |

| Pet products | Pet beds, plush squeaky toys | Comfort and play for animals |

| Fashion & accessories | Plush bags, keychains, hats | Fun, trend-driven, youthful image |

| Corporate & promo | Mascot plush, logo plush keyrings | Brand promotion and emotional connection |

Why brands choose plush for extensions

Plush materials help brands:

- Add a cozy edge to functional products (like travel pillows).

- Carry character IP across many product categories.

- Create giftable items with high perceived value but manageable cost.

For example, a children’s book character might appear as a plush toy, a plush cushion, and a plush backpack clip. For the end consumer, all of these feel related because the plush texture and character style are consistent.

As a manufacturer, we see more and more clients ask for such cross-category plush items. For many of them, “plush” is becoming part of their brand language, not just a material choice.

How do market trends influence the evolving meaning of “plush”?

The meaning of “plush” is not fixed. Market trends reshape it over time. What counted as “plush” in the past—maybe just a basic teddy bear—now includes weighted plush, reversible plush, eco plush, anime-style plush, and more. Each trend adds new expectations around design, function, and story.

Currently, I see several strong forces: sustainability, mental wellness, fandom culture, and social media aesthetics. These trends change how customers talk about plush, what they search for online, and which products retailers want from factories like ours.

(Image suggestion: flat lay of a weighted plush, an eco-labeled plush, and a stylized anime plush.)

Key trends shaping the modern idea of “plush”

You can understand today’s plush market through a few main trend lines:

Table 6 – Market trends and their impact on “plush”

| Trend Area | What Customers Expect from Plush | How “Plush” Meaning Shifts |

|---|---|---|

| Sustainability | Recycled fabrics, clear eco stories | Plush = soft + planet-conscious |

| Mental wellness | Weighted plush, calming colors, gentle faces | Plush = comfort, stress relief, emotional care |

| Fandom & IP | Character accuracy, collectibility | Plush = physical expression of fandom |

| Social media style | Cute, photogenic, “aesthetic” designs | Plush = lifestyle accessory, not just toy |

How brands and factories respond to these shifts

For brands, this means that a “plush line” must align with broader values, not just basic softness. Examples we see in real projects:

- Switch from standard fiberfill to recycled fiber and adding hangtags that explain the eco story.

- Developing weighted plush products that support relaxation, not only play.

- Designing collector editions with limited colorways or special packaging for fans.

- Creating plush that fits into Instagram- or TikTok-friendly color palettes and room styles.

At Kinwin, we adapt by sourcing new materials, updating our QC and testing processes, and guiding clients through the trade-offs between trend, safety, cost, and performance.

For you as a buyer, retailer, or brand owner, it helps to see “plush” as a living concept. It still means soft, stuffed, and comforting—but it also carries signals about lifestyle, values, and community. When you design or select plush products with these layers in mind, your offers feel more current, more meaningful, and more competitive.

Conclusion

In modern markets, “plush” means far more than just soft fabric. It combines material, construction, safety, emotion, and brand story into one powerful product type. When you choose the right plush fabrics, work with reliable manufacturing techniques, and stay close to trends like sustainability and mental wellness, your plush lines can stand out and stay relevant for many seasons. At Kinwin, we help global buyers turn ideas and characters into well-made plush products that feel truly “plush” in every sense—soft to touch, strong in quality, and rich in meaning for end users. If you are planning a new plush project or refining an existing range, you are welcome to reach me at [email protected] or visit kinwintoys.com to explore how our factory can support your success.