The plush toy industry has transformed dramatically in the last decade, and one of the most influential changes has been the adoption of 3D modeling. What used to rely heavily on hand sketches and trial-and-error sampling is now supported by digital sculpting, precision geometry, and simulation tools that help brands and factories predict real-world results before cutting a single piece of fabric.

For global buyers, 3D modeling creates clearer communication, fewer sampling rounds, lower development costs, and more consistent mass production outcomes. This guide explains how 3D modeling enhances every stage of plush toy design—from concept accuracy to final pre-production approval.

How 3D Modeling Improves Accuracy in Character Shape and Proportion?

Traditional plush design often relies on 2D character sheets that show the front, side, and back views. While useful, these views cannot fully capture the volumetric structure of a plush toy. A character with a stylized head, exaggerated limbs, or unique silhouette may look perfect in 2D but appear distorted once translated into fabric shapes.

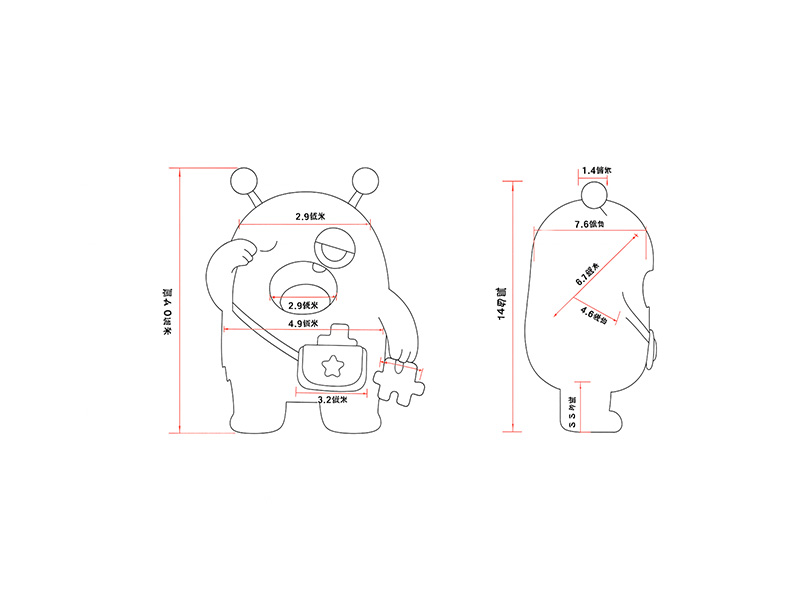

3D modeling solves this challenge by creating a complete volumetric form that represents the final plush geometry far more accurately. Designers can rotate the model from any angle, measure exact proportions, and confirm how the head compares to the body, how limbs attach, and how curves translate into real-world shapes.

Using 3D tools, creators can test exaggerated proportions, scale adjustments, and shape balance before passing the design to pattern makers. This is especially useful for licensed characters, where accuracy is essential, and for stylized characters requiring precise visual identity.

| Benefit of 3D Modeling | Description | Impact on Plush Design |

|---|---|---|

| Shape accuracy | True 3D volume reference | Prevents distortion |

| Proportion control | Exact geometric measurements | Higher aesthetic fidelity |

| Rotatable views | 360° inspection | Eliminates guesswork |

| Stylized features | Experiment with shapes quickly | Better creative execution |

| Consistency | Same reference for all teams | Reduces errors |

What Advantages Digital Sculpting Offers Over Traditional 2D Concepting?

While 2D concept drawings remain important for defining character personality and expression, digital sculpting offers deeper control over structure, curvature, and dimensional detail. Tools like ZBrush, Blender, or Nomad Sculpt allow designers to create lifelike forms with fine surface detail and optimized symmetry.

Unlike hand drawings, which can be interpreted differently by different departments, a 3D sculpt provides a unified reference that removes ambiguity. Pattern makers, sample makers, project managers, and licensors all reference the same geometry. This speeds up decision-making and ensures that details like nose placement, curve angles, and body fullness remain consistent.

Digital sculpting also allows rapid iteration. Designers can adjust scale, silhouette, or pose in minutes instead of redrawing full turnarounds. This flexibility reduces the typical number of sampling rounds needed and lowers development time and cost.

| Comparison | 2D Concepting | 3D Sculpting |

|---|---|---|

| Accuracy | Open to interpretation | Exact, measurable |

| Iteration speed | Slow redraws | Fast adjustments |

| Detail control | Limited by perspective | Full-depth modeling |

| Cross-team consistency | Varies by viewer | Universal reference |

| Suitability for complex shapes | Challenging | Ideal |

How 3D Models Support Efficient Pattern Making and Fabric Layout Planning?

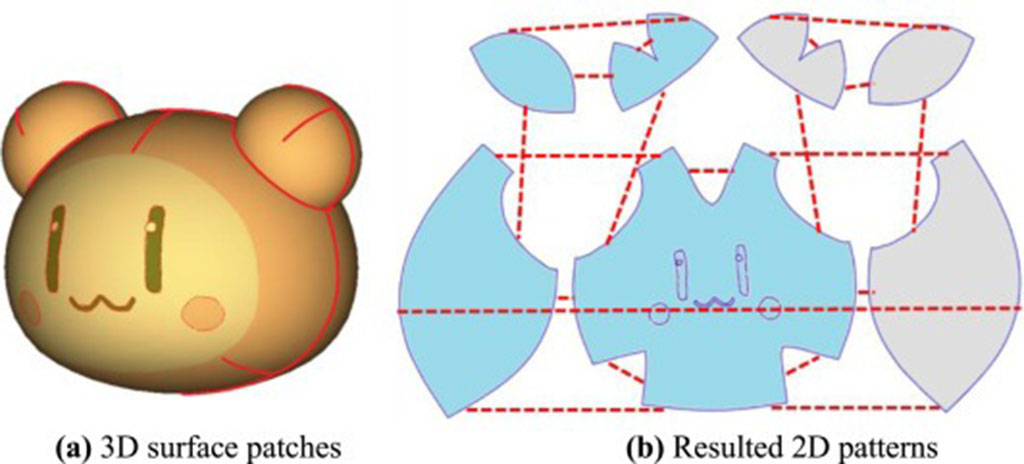

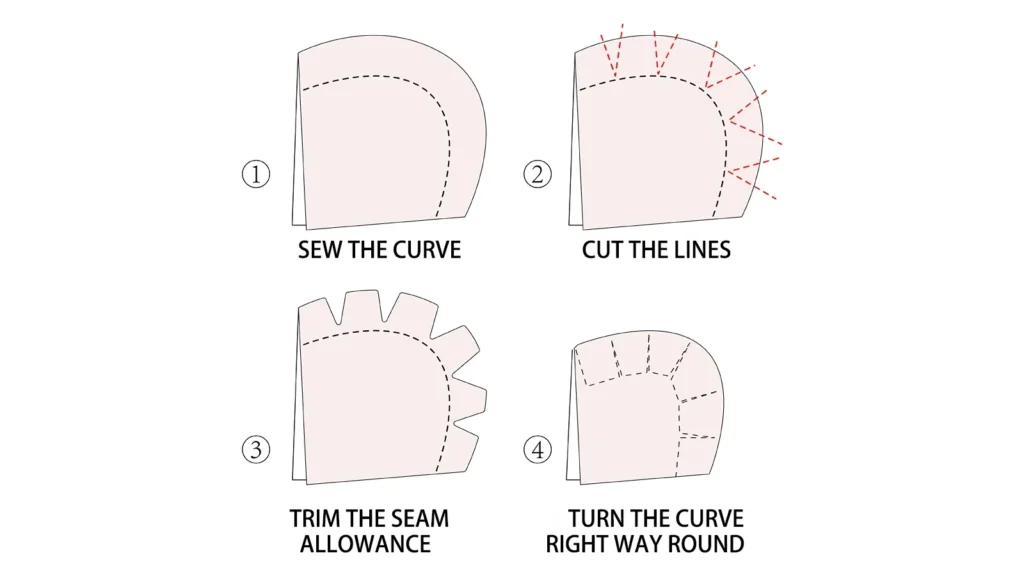

Pattern makers convert character geometry into flat fabric shapes, but this process becomes much easier when supported by a 3D model. In traditional workflows, pattern makers interpret 2D drawings, make educated guesses, and adjust repeatedly through sampling. A 3D model removes most uncertainty.

Using 3D-assisted pattern tools, pattern makers can project surfaces, test panel shapes, and map seam lines directly onto the model. This ensures that each piece contributes to the correct curvature and overall volume.

Fabric layout planning also improves because pattern makers can predict coverage more accurately, helping reduce waste and optimize fabric consumption. This is especially valuable for premium materials such as faux fur, high-pile minky, or specialty textured fabrics.

| Pattern-Making Enhancement | 3D Support Provided |

|---|---|

| Surface projection | Converts curves into flat patterns |

| Seam visualization | Shows how lines affect shape |

| Panel mapping | Ensures symmetry and balance |

| Fabric yield estimation | Predicts material consumption |

| Efficiency improvement | Reduces trial-and-error |

How Factories Use 3D Assets to Visualize Structure, Seams, and Construction Details?

Factories often use 3D models to improve internal communication among pattern makers, sewing technicians, and project teams. A detailed model helps each department understand structural elements such as seam placement, stuffing requirements, and the internal architecture of the plush.

3D models can highlight potential problem areas—thin limbs, top-heavy heads, tight curves, or structural stress points—before sampling begins. This allows engineering adjustments early, such as reinforcing seam areas, modifying angles, or adjusting panel shapes to improve durability.

Factories also use 3D models during the training of sewing teams. Workers who have never seen the cartoon or IP character can visualize the final plush in 3D, helping them understand how each sewing step contributes to the final shape.

| Construction Detail | 3D Model Visualization Advantage |

|---|---|

| Seams | Shows exact placement for accuracy |

| Reinforcement areas | Identifies stress points |

| Accessory attachment | Simulates placement and scale |

| Curves & contours | Helps prevent distortion |

| Panel alignment | Ensures matching edges |

How 3D Simulation Helps Predict Stuffing Behavior and Final Plush Form?

Stuffing behavior is one of the most unpredictable aspects of plush toy engineering. A plush toy can look perfect in patterns, but tone, softness, and shape may change dramatically once filled. 3D simulation tools help predict how different stuffing densities, bead weights, or foam inserts will behave inside the plush.

Simulations show how volume expands, how seams react to pressure, and whether the toy will maintain its intended proportions. Factories can test various firmness levels, allowing designers to choose the right filling strategy before creating physical samples. This cuts down sampling rounds and reduces material waste.

For plush toys with structured shapes—standing animals, mascots, figurine-like characters—3D simulation is valuable for stability testing. Factories can predict whether the plush will stand upright, remain balanced, or require weighted beads or internal foam.

| Stuffing Variable | Simulated Outcome |

|---|---|

| Density | Soft vs. firm appearance |

| Fiber type | Elasticity and rebound |

| Weighted beads | Stability improvement |

| Internal foam | Shape retention |

| Multi-zone stuffing | Balanced texture |

How 3D Modeling Streamlines Sampling, Revisions, and Pre-Production Approval?

A major advantage of 3D modeling is its ability to shorten the sampling timeline. Since the model provides a clear geometric guide, the first sample typically comes closer to the designer’s intention. This means fewer prototype iterations, less material waste, and lower sampling cost.

During revisions, designers and factories can overlay the physical sample and 3D model to identify discrepancies. Adjustments—such as modifying panel curves, shifting facial features, or increasing volume in certain areas—are easier to communicate when both parties reference the same digital model.

By the time the project reaches the Pre-Production Sample (PPS) stage, the 3D model ensures that the final version is fully aligned with the approved geometry, proportion, and character identity. It also becomes a long-term reference for future production reruns.

| Sampling Stage Benefit | 3D Modeling Effect |

|---|---|

| First sample accuracy | Higher precision |

| Revision clarity | Clear visual reference |

| Engineering alignment | Consistent across teams |

| PPS approval | Faster and more exact |

| Long-term reproduction | Ensures consistency |

Conclusion

3D modeling has become one of the most powerful tools in modern plush toy development. It strengthens communication, reduces sampling time, improves shape accuracy, enhances engineering decisions, and ensures consistent results from concept to mass production. For global brands working with overseas factories, adopting 3D modeling is no longer optional—it’s a strategic advantage that saves cost, time, and risk. Factories like Kinwin help buyers integrate 3D workflows into their projects to achieve smoother development and industry-leading quality.

📧 Contact: [email protected]

🌐 Visit: https://kinwintoys.com